A: We pay great attention with the quality of our products and we have many quality certificates: ISO9001, ISO14001, CE European Union certification certificate, ROHS certificate etc.

Applicable industries of QE/QH series:

High precision measure equipment,Semiconductor equipment,Automatic equipment, can be widely applied in high-tech industry required high speed,low noise,low dust generation.

⑴ Low Noise Design

With SynchMotion technology, rolling elements are interposed between the partitions of SynchMotion to provide improved circulation. Due to the elimination of contact between the rolling elements, collision noise and sound levels are drastically reduced.

⑵ Self-Lubricant Design

The partition is a grouping of hollow ring-like structures formed with a through hole to facilitate circulation of the lubricant. Because of the special lubrication path design, the lubricant of the partition storage space can be refilled. Therefore, the frequency of lubricant refilling can be decreased.This is linear guideway is pre-lubricated. Performance testing at a 0.2C (basic dynamic load) shows that after running 4,000km no damage was apparent to either the rolling elements or the raceway.

⑶ Smooth Movement

In standard linear guideways, rolling elements on the load side of the guide block begin rolling and push their way through the raceway. When they contact other rolling elements they create counter-rotational friction. This results in a great variation of rolling resistance. The QH linear guideway, with SynchMotion technology prevents this condition. As the block starts to move, the rolling elements begin rolling consecutively and remain separated to prevent contact with one another thus keeping the element’s kinetic energy extremely stable in order to effectively reduce fluctuations in rolling resistance.

(4) High Speed Performance

This kind of series offers excellent high-speed performance due to the partitions of the SynchMotion structure. They are employed to separate the adjacent balls thereby resulting in low rolling traction and the metallic friction between adjacent balls is eliminated.

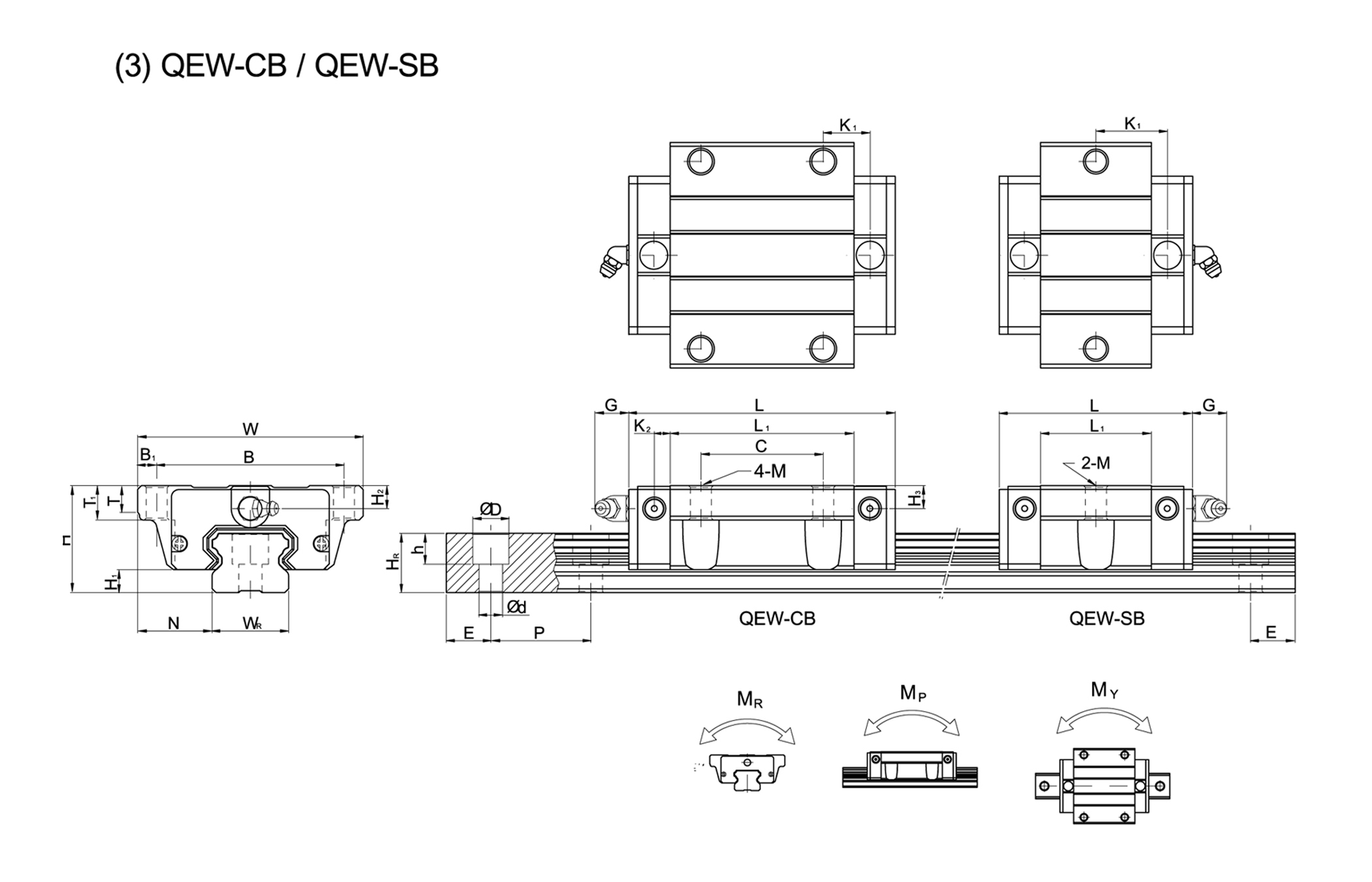

Model NO. | Dimensions of | Dimensions of | Dimensions of | Mounting Bolt for Rail | Basic Dynamic Load Rating | Basic Static Load Rating | Static Rated Moment | Weight | ||||||||||||||||||||||||

MR | MP | MY | Block | Rail | ||||||||||||||||||||||||||||

H | H1 | N | W | B | B1 | C | L1 | L | K1 | K2 | G | M | T | T1 | H2 | H3 | WR | HR | D | h | d | P | E | (mm) | C(kN) | C0(kN) | ||||||

QEW15SB | 24 | 4 | 18.5 | 52 | 41 | 5.5 | – | 23.1 | 40.1 | 14.8 | 3.5 | 5.7 | ø5 | 5 | 7 | 5.5 | 6 | 15 | 12.5 | 6 | 4.5 | 3.5 | 60 | 20 | M3x16 | 8.56 | 8.79 | 0.07 | 0.03 | 0.03 | 0.12 | 1.25 |

QEW15CB | 26 | 39.8 | 56.8 | 10.15 | 12.53 | 15.28 | 0.12 | 0.09 | 0.09 | 0.21 | ||||||||||||||||||||||

QEW20SB | 28 | 6 | 19.5 | 59 | 49 | 5 | – | 29 | 50 | 18.75 | 4.15 | 12 | ø6 | 7 | 9 | 6 | 6.5 | 20 | 15.5 | 9.5 | 8.5 | 6 | 60 | 20 | M5x16 | 11.57 | 12.18 | 0.13 | 0.05 | 0.05 | 0.19 | 2.08 |

QEW20CB | 32 | 48.1 | 69.1 | 12.3 | 16.50 | 20.21 | 0.21 | 0.15 | 0.15 | 0.31 | ||||||||||||||||||||||

QEW25SB | 33 | 6.2 | 25 | 73 | 60 | 6.5 | – | 35.5 | 60.1 | 21.9 | 5 | 12 | ø8 | 7.5 | 10 | 8 | 8 | 23 | 18 | 11 | 9 | 7 | 60 | 20 | M6x20 | 18.24 | 18.90 | 0.22 | 0.10 | 0.10 | 0.34 | 2.67 |

QEW25CB | 35 | 59 | 83.6 | 16.15 | 16.03 | 31.49 | 0.37 | 0.29 | 0.29 | 0.58 | ||||||||||||||||||||||

QEW30SB | 42 | 10 | 31 | 90 | 72 | 9 | – | 41.5 | 67.5 | 25.75 | 6 | 12 | ø10 | 7 | 10 | 8 | 9 | 28 | 23 | 11 | 9 | 7 | 80 | 20 | M6x25 | 26.27 | 27.82 | 0.40 | 0.18 | 0.18 | 0.61 | 4.35 |

QEW30CB | 40 | 70.1 | 96.1 | 20.05 | 37.92 | 46.63 | 0.67 | 0.51 | 0.51 | 1.03 | ||||||||||||||||||||||

QEW35SB | 48 | 11 | 33 | 100 | 82 | 9 | – | 51 | 76 | 30.3 | 6.25 | 12 | ø10 | 10 | 13 | 8.5 | 8.5 | 34 | 27.5 | 14 | 12 | 9 | 80 | 20 | M8x25 | 36.39 | 36.43 | 0.61 | 0.33 | 0.33 | 0.77 | 6.14 |

QEW35CB | 50 | 83 | 108 | 21.3 | 51.18 | 59.28 | 1.00 | 0.75 | 0.75 | 1.19 | ||||||||||||||||||||||

Note:1kgf = 9.81N | ||||||||||||||||||||||||||||||||

A: We pay great attention with the quality of our products and we have many quality certificates: ISO9001, ISO14001, CE European Union certification certificate, ROHS certificate etc.

A: Yes, sample is available. If you are interested, you can contact us by e-mail ([email protected]) to get more photos and information.

A: Normal order delivery of linear motion products is generally controlled within 1-2 months.

Normal order delivery for linear unit and higher precision products is generally controlled within 7-15 working days.

A: Our cooperating transportation companies include DHL, TNT, UPS, etc. Sea transportation, air transportation and express delivery are all available. If you have a specific carrier, please let us know when you place the order.

A: You can contact us by e-mail ([email protected] ) and we will recommend the most suitable project according to your requirements.

A: T/T in advance.

A: LIMON agent in Asia: Singapore, Japan, India

LIMON agent in Europe: Hungary, Turkey, Israel

LIMON agent in South America: Brazil

A: LIMON do quite well in Europe, Asia and South America, also China is a potential market for us. Now LIMON’s distributors have covered more than 32 country and regions.

A: We are really looking forward to having you as a solid partner of LIMON. Please contact us by e-mail ([email protected] ) , we can start talk and get to know more about each other.

Welcome to discuss your purchasing requirements with our customer service.