The hollow rotary actuator is driven by motor to realize automatic Angle adjustment. Finishing worm gear or gear drive, Angle adjustment unlimited. Precision shafting design, ensure precision high, large load; Stepper motor and transmission parts are connected through imported high-quality elastic couplings to eliminate space and machining position errors.

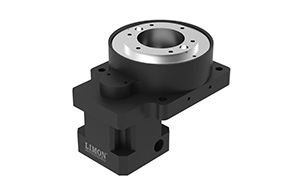

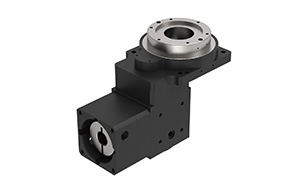

Hollow Rotary Actuator

Hollow Rotary Actuator

The Hollow Rotary Actuator is one kind of product for the circular motion between the cam index and DD motor. With a balance between the two, the repetitive positioning accuracy is no more than 5 seconds, the motor is easy to prepare and the load is stable. It can be matched with AC servo motor or stepper motor for arbitrary Angle segmentation, which can realize the multi-point orientation as DD motor but also has better cost performance than DD motor. And it is widely used in diverse rotary applications.

Characteristic:

- High load

- High stiffness

- Digital control

- Multi-points positioning

- High positioning accuracy

- Arbitrary configuration of motor

- Replace six-axis solution

DY200 Hollow Rotary Actuator

DY130 Hollow Rotary Actuator

DY85 Hollow Rotary Actuator

DY60 Hollow Rotary Actuator

How does hollow rotary actuator work?

Technical Blogs

Knowleage

How accurate are hollow rotary actuator?

Accurate data: Now LIMON hollow rotary actuators are sized in 60, 85, 135, 200. The surface is through high and middle heat treatment which the grinding precision can be ISO6 and surface hardness HRC 65. Also the repetitive accuracy is ±15arc-sec, and concentricity&flatness ±0.05 mm.

What is the advantage of a hollow rotary actuator?

- Large-Diameter, Hollow Output Table Makes Simple Wiring and Piping Possible

- Contributes to Easier Equipment Design

- High Power and Rigidity

- Direct Coupling for Higher Reliability

- Bottom and Workbench Contact, except the four screw holes, the center ring directly below the bearing also contacts the worktable.

- Our pinion module is larger than other brands, other brand modulus is 0.8-0.9, we are 1.25, so at high deceleration ratio of 18, our gear strength is better.

- There are steel rings at the bottom, and the load is borne by steel parts, in case the bearing presses the aluminium structure to deform clearance.

- An integrated design of gear and cross roller bearings is under developing, it can improve rotation accuracy and stability.

- Electroless nickel plating on working face, heat-treat, to prevent rusting and scratching.

What is a hollow rotary actuator used for?

Now the hollow rotary actuator is applied in different industries especially in the 3C industry like the grinding machine of mobile phone shells, also visual testing equipment, Laser equipment industry, Semi-conduct equipment industry, also highly matched with the linear module for some applications, etc. It can be used for applications in which accurate positioning and heavy load tolerance capacity is a must.

What is the difference between linear actuator and rotary actuator?

A linear module moves in a straight line, usually in a back and forth motion. In contrast, a hollow rotary actuator moves along a circle at a specific Angle with reference to the midpoint of the circle, enabling 360 degrees of multi-point positioning.