The unique element of ball screws is the rolling balls in the helical groove which reduces the mechanical contact inside the linear ball screw assembly and replaces sliding friction with rolling friction. This mechanism significantly lessens the friction generated, which results in highly efficient power conversion. The efficiency of screws is measured by their capability to transform power utilized in exerting rotational force to the linear distance covered.

How is linear ball screw composed?

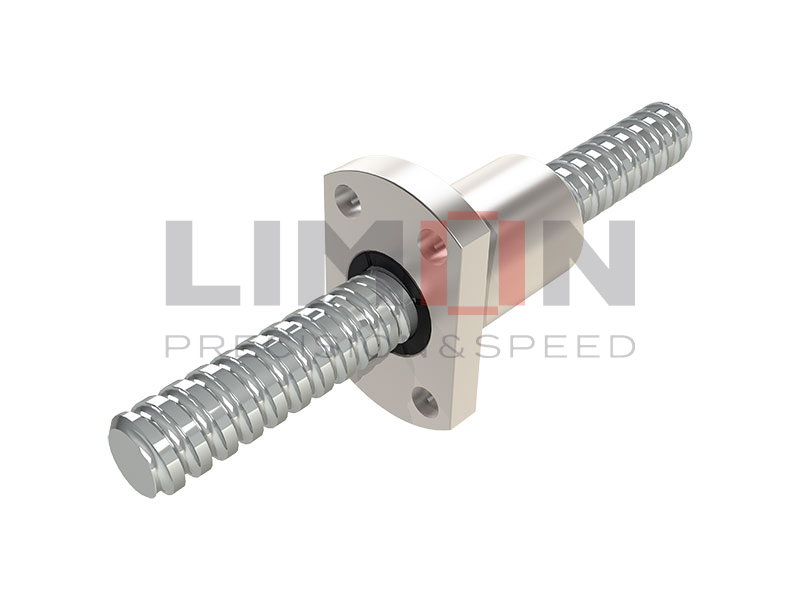

The main components of ball screws are the linear ball screw, ball screw nut, and the balls. We will discuss their important specifications and their impact on the operation.

What is linear ball screw types?

Ball screws may be categorized according to the mechanism of their ball recirculation. The ball recirculation mechanisms are grouped into internal recirculation and external recirculation systems.Internal Ball Recirculation, Deflector-Type Ball Screws, End Cap-Type Ball Screws, External Ball Recirculation.

We have different types of ball screws, we have rolled screws and ground screws, the precision of ground screw can reach to C3, the rolled screw can reach to C5.

How does a linear ball screw work?

A ball screw works in a similar way to a conventional lead screw, but the significant advantage of using a ball screw is that it uses balls running in the helical channel to transmit the load. In high precision applications it is often necessary to translate the rotary motion from a motor to linear motion for the payload. One way of achieving this is by using a linear ball screw.Ball bearings within a ball screw roll along the track in a similar way to ball bearings in a standard rotary ball race, therefore eliminating the sliding friction associated with linear ball screws. The ball bearings are continually recirculated through the ball screw nut, distributing the load and picking up lubrication along the way. Due to the use of rolling ball bearings within a ball screw, the internal friction is very low, meaning ball screws can offer a high level of efficiency and positional accuracy even at high torque and force loadings. Ball screws can be quite complicated and high-precision devices, meaning they can sometimes be slightly more costly compared to a typical lead screw. This is due to the complex machining and assembly techniques required to manufacture them. However, if your application requires a ball screw, the greater performance generally outweighs the cost.

What are the features of linear ball screw?

There are many advantages of using ball screws within your motion application:

- Highly efficient, requiring less torque – therefore smaller motor

- Higher accuracy grades for greater positional accuracy

- Lower friction – able to run at cooler temperatures

- Available in rolled and ground types

- Can be adjusted to increase/decrease preload

- Need to be replaced less frequently

- Available in screw diameters from 12mm to 80mm

What may cause premature failure of linear ball screws or ball screw nuts?

There are many factors that could lead to premature failure of a ball screw or ball nut. Several of the most common are listed below

- Lack of lubrication. Proper lubrication will help dissipate heat and reduce metal-to-metal wear of components. Insufficient lubrication is one of the primary reasons for premature ball screw or ball nut failure.

- Dirt or debris in the ball nut or ball paths preventing free circulation of the ball bearings. The ball bearings may get flats on them due to skidding and spalling, which may in turn damage the ball paths in the screw or the ball nut.

- Misalignment of the ball nut to screw which results in side loading or eccentric loading. It is very important that the ball nut only experiences axial loading. Side loading or eccentric loading may cause the ball bearings to wear flat in places. The bearings may even break out of the return tubes.

- Excessive speed. Exceeding the ball nut critical speed can lead to pickup fingers breaking, which will allow to the ball bearings to come out of the nut. Exceeding the screw critical speed will cause the screw to whip or vibrate and cause misalignment. Shaft speeds resulting in screw surface speeds above 8,000 inches per minute will reduce rated life.

- Others.

Where is a linear ball screw used?

Due to the small frictional resistance, ball screw are widely used in a variety of industrial equipment and precision instruments. Ball screws are used for heavy-duty applications requiring high speed, high throughput, high accuracy, and long service times. They are used in precise positioning systems, in automotive steering systems, in electric vehicles, in energy-generating machinery such as wind turbines, solar panels, and hydroelectric equipment, in aircraft machinery, and as a viewing system for the photolithography process.

Reasons to Choose LIMON Ball Screws

LIMON is the leading supplier of linear components. In order to meet customer’s demands, we are always keeping the pace of making innovations and developing new products and technical reformation. LIMON involved in ball screw industry from 2007 and with professional technical and sales team, now we sell very well and has dealers in European, Asian and South American countries. Feel free to contact us, if there is any question.