When precision, speed, and longevity are non-negotiable, many industries turn to the linear motor actuator. But along with its premium performance comes a higher price tag compared to the traditional ball screw linear actuator. So—what drives this cost?

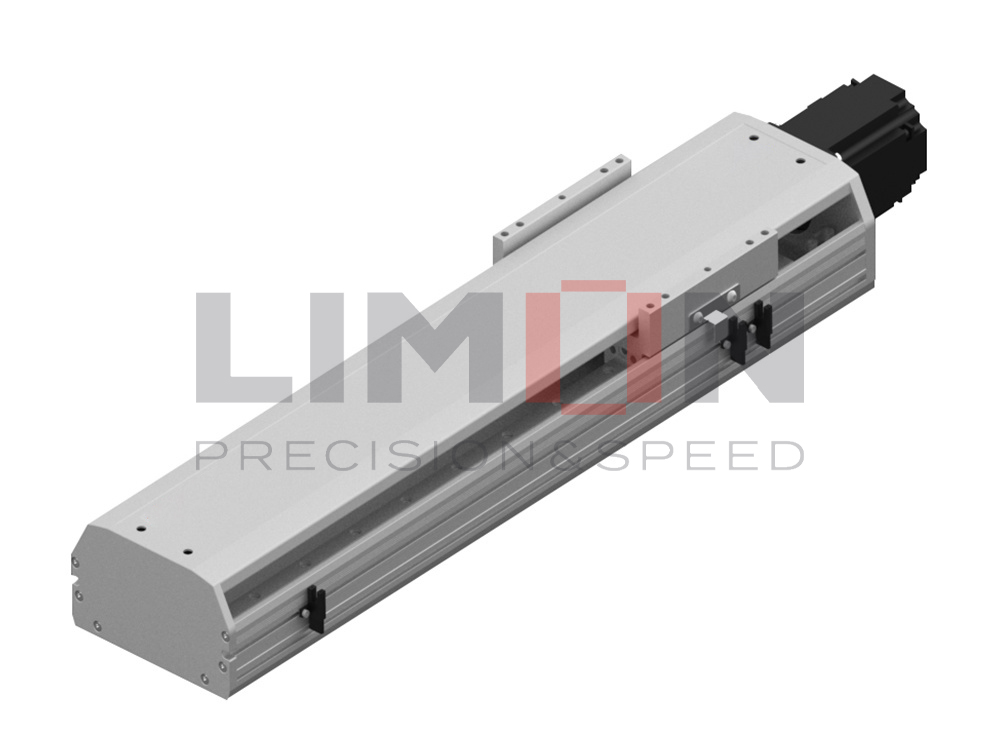

Core Component: Electromagnetic Drive System

The linear motor operates on a fundamental shift in motion mechanics. Instead of converting rotary motion into linear movement, it creates direct linear motion using an electromagnetic drive system. This system consists of:

A primary coil (stator) that generates a magnetic field

A secondary moving magnet (forcer) that rides the magnetic field to produce motion

This contactless drive removes all intermediate mechanical parts—no screws, no belts, no gears. The result? Near-zero friction, zero backlash, and ultra-smooth, high-speed performance.

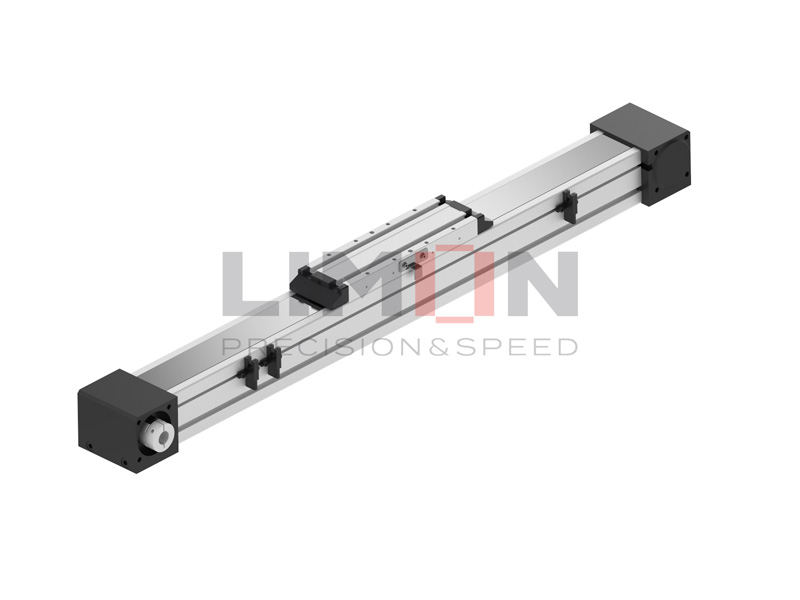

Why Is a Linear Motor Actuator More Expensive Than a Ball Screw Linear Actuator?

Several factors contribute to the higher cost of linear motor actuators—and each one ties directly to performance advantages:

1. Advanced Design, Zero Compromise

Unlike ball screw actuators, linear motors don’t rely on mechanical contact. This means:

No component wear

No mechanical backlash

No need for constant realignment or lubrication

They offer clean, contactless motion—ideal for high-precision environments like semiconductors and advanced robotics.

2. Superior Motion Performance

Linear motors excel in:

Acceleration

Top-end speed

Sub-micron positioning accuracy

This makes them the go-to choice for tasks where speed and precision must coexist, such as laser cutting, pick-and-place systems, or medical diagnostics.

3. High-End Materials and Complex Engineering

Building a linear motor actuator involves:

Premium magnets (often rare earth materials)

Precision-engineered windings

Sophisticated controllers and encoders

These components don’t come cheap—and neither does the advanced assembly process that ensures long-term performance with minimal maintenance.

4. Improved Energy Efficiency and Heat Dissipation

Without mechanical drag, a linear motor naturally:

Runs cooler

Converts power into motion more efficiently

Requires less frequent maintenance interventions

These operational advantages translate into a lower total cost of ownership over time, even if the initial investment is higher.

Summary

Yes, linear motor actuators come with a higher price tag—but what you gain in return is next-level performance:

Direct drive without wear-and-tear components

Precision at speed, with exceptional control

Lower maintenance and longer service life

Greater energy efficiency for long-term ROI

In industries where reliability and motion accuracy are mission-critical, the choice is clear.

Explore Precision Motion with LIMON

Looking to upgrade to a linear motor actuator? Visit LIMON for expert-engineered solutions that deliver superior motion control, long-term durability, and industry-leading support.

2.jpg)