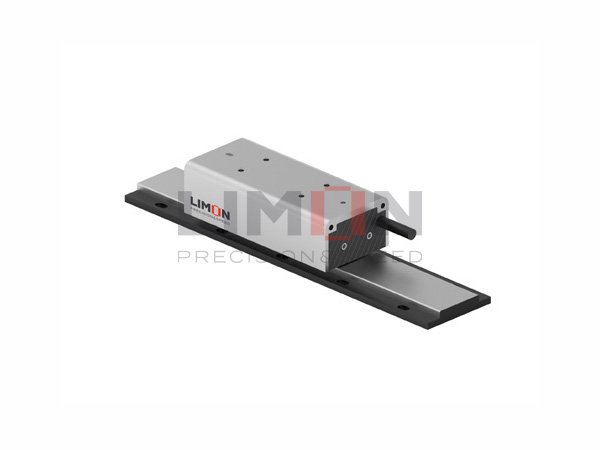

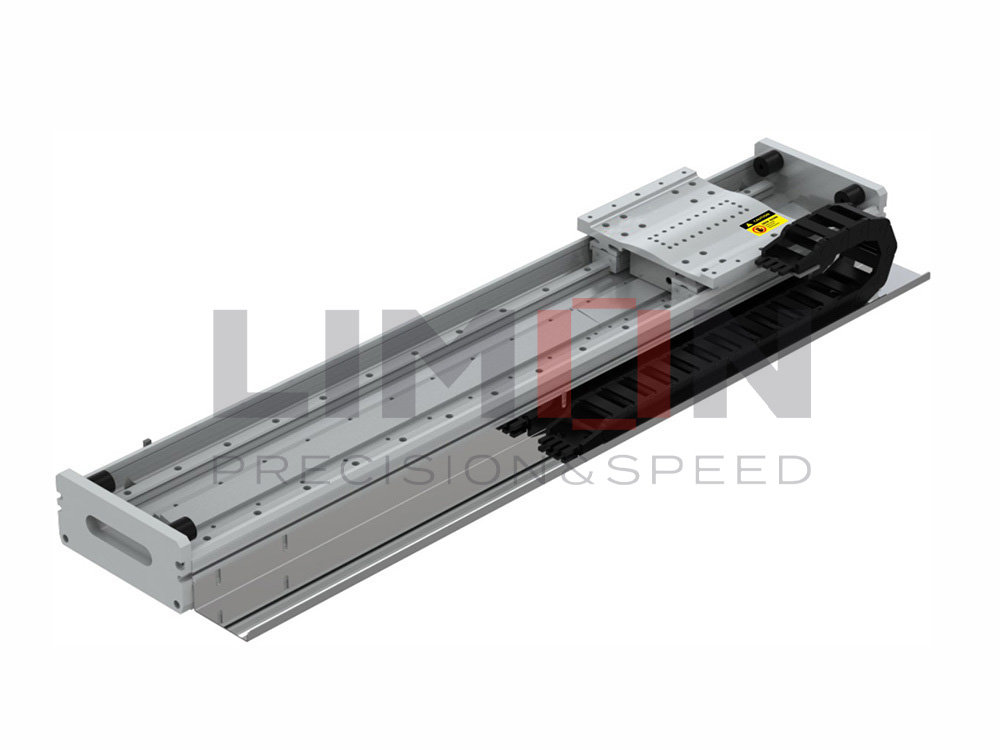

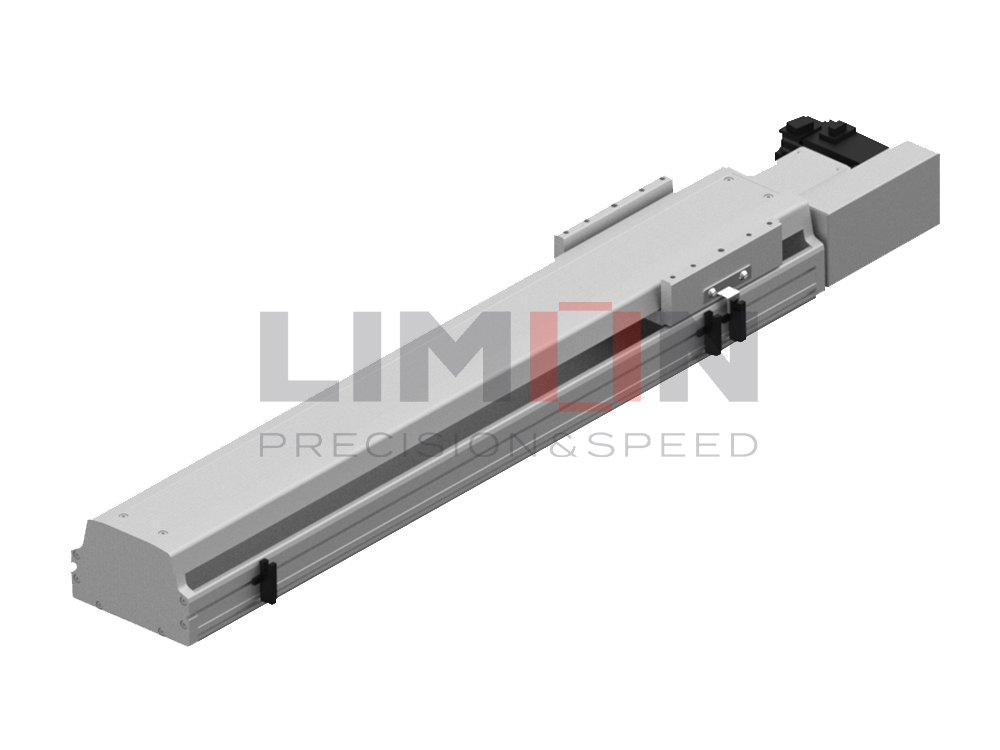

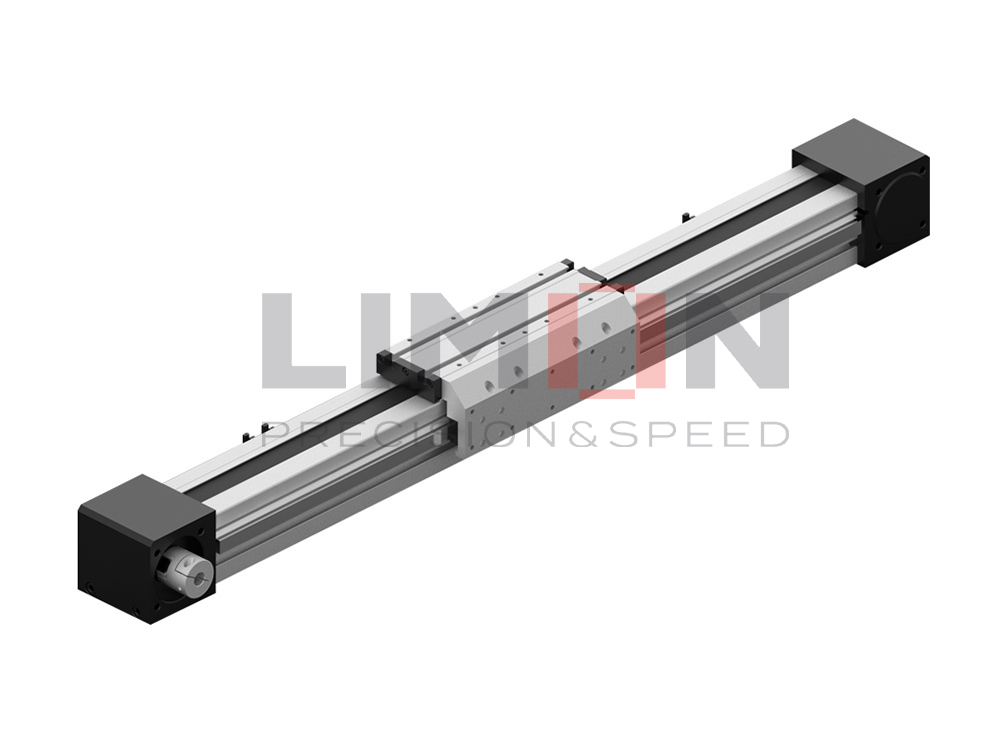

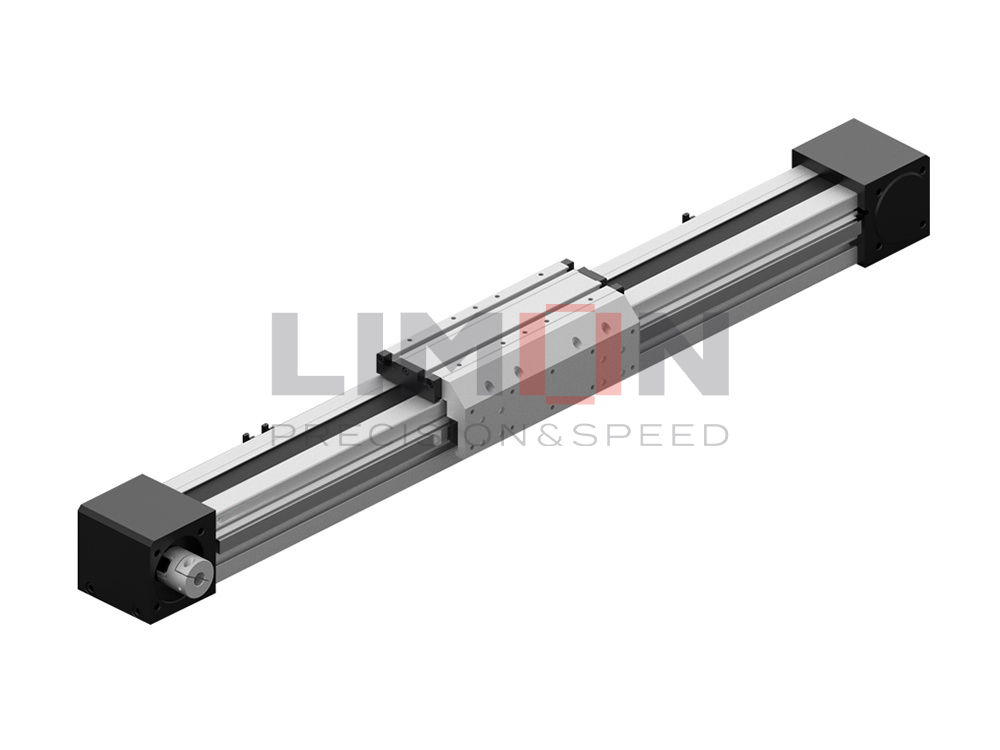

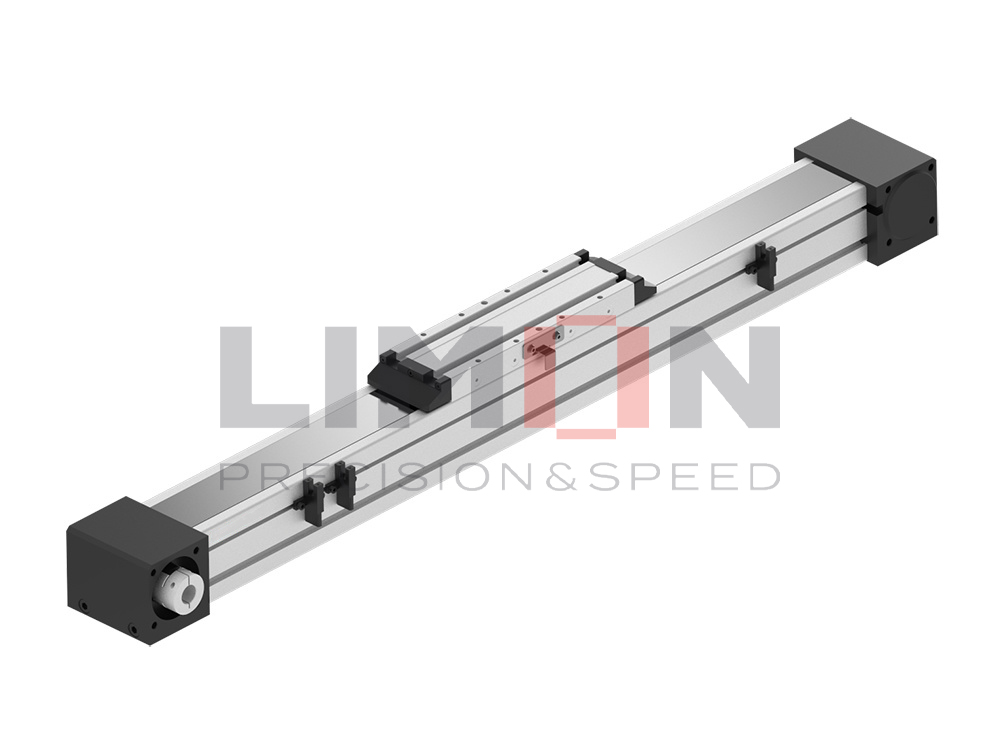

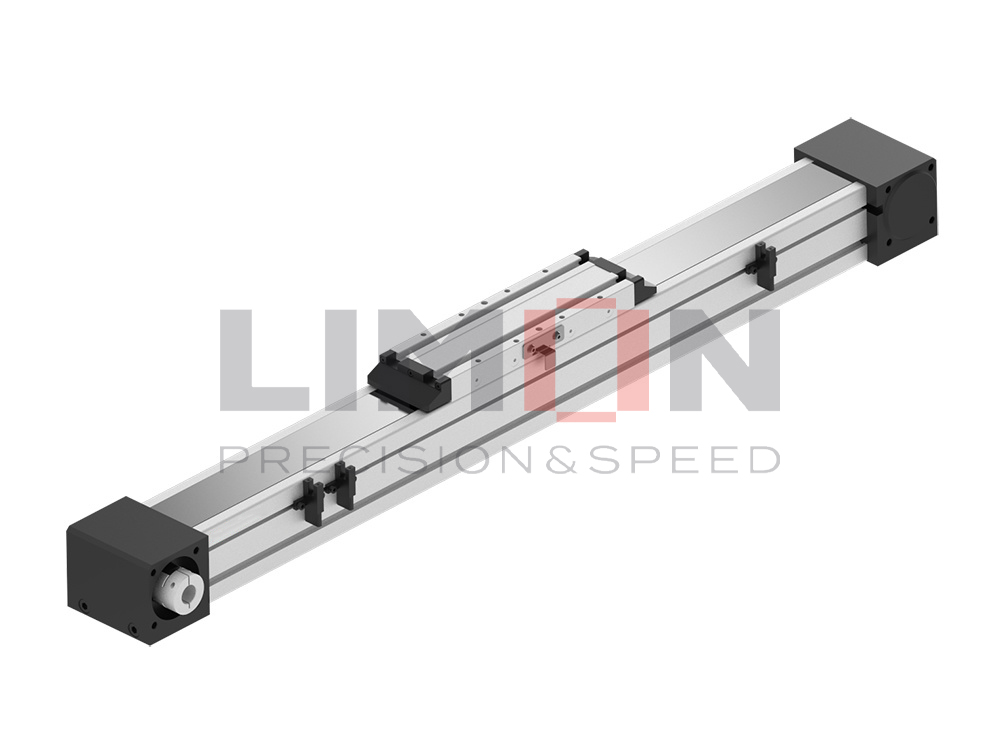

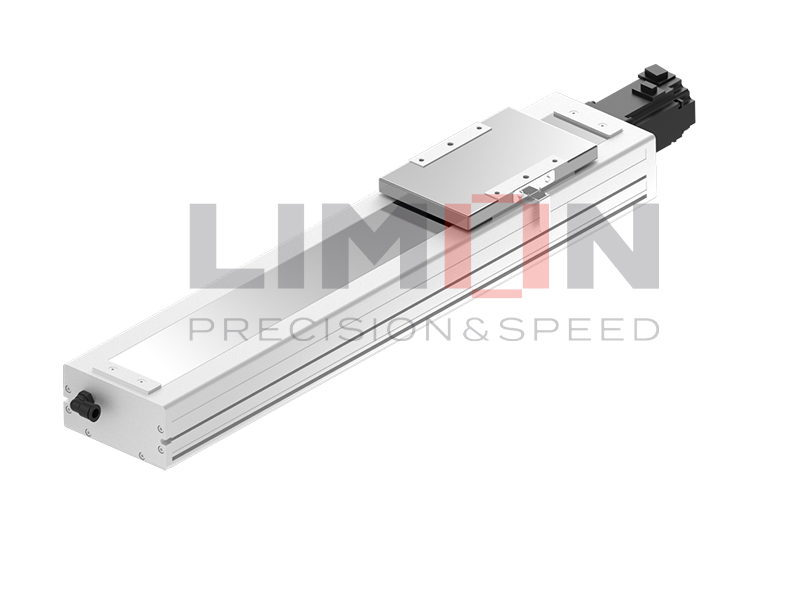

- Belt driven type linear module

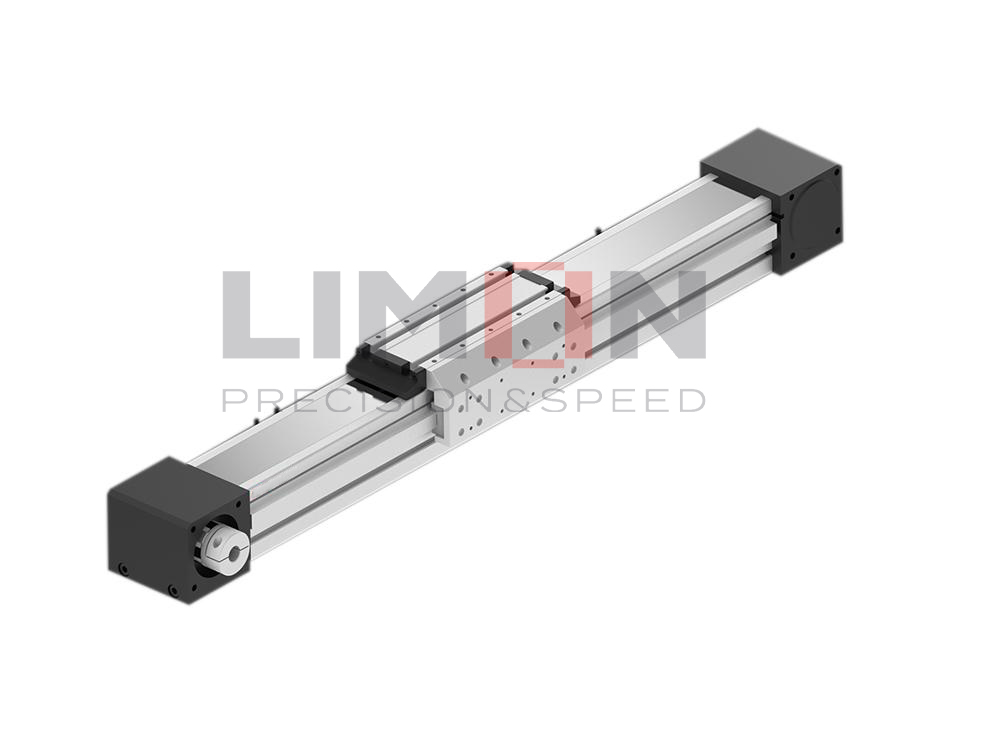

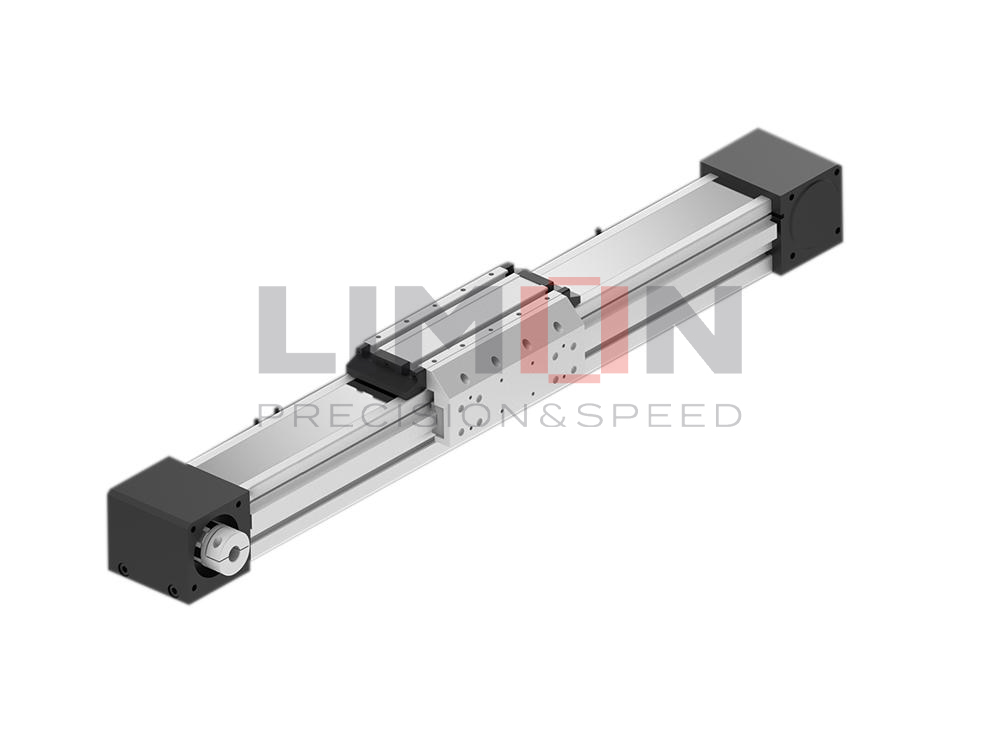

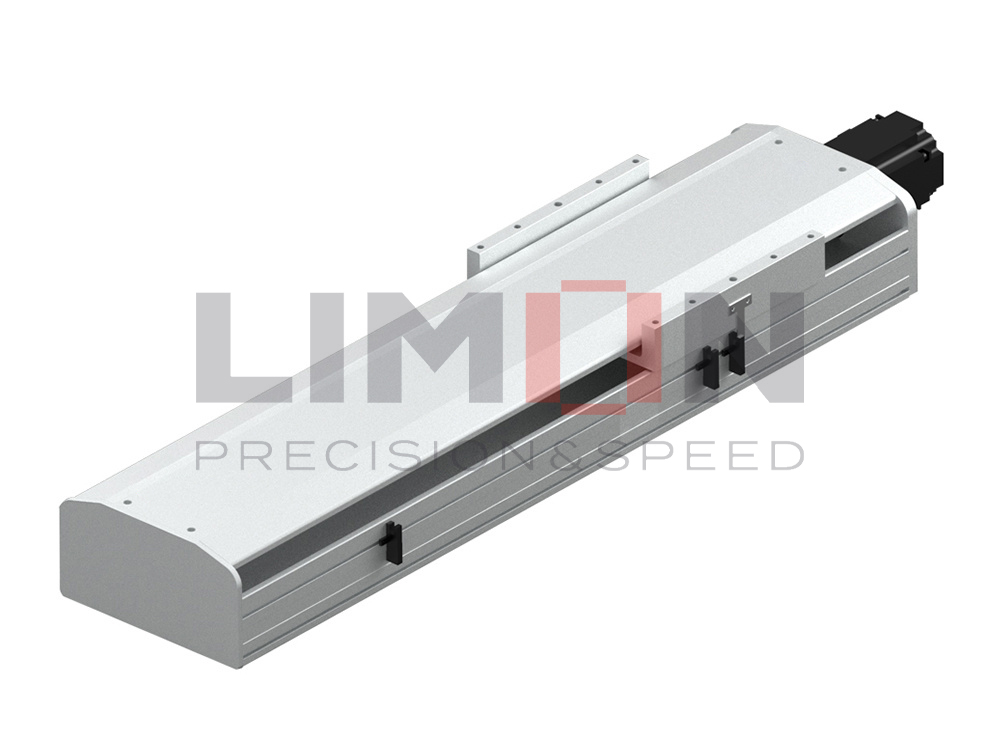

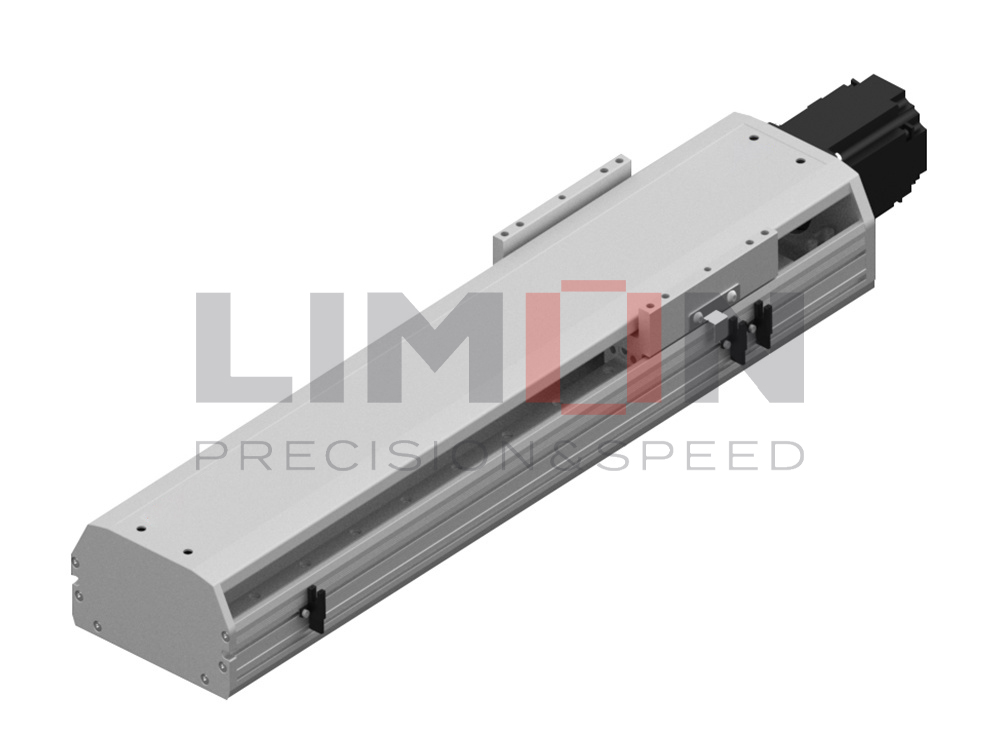

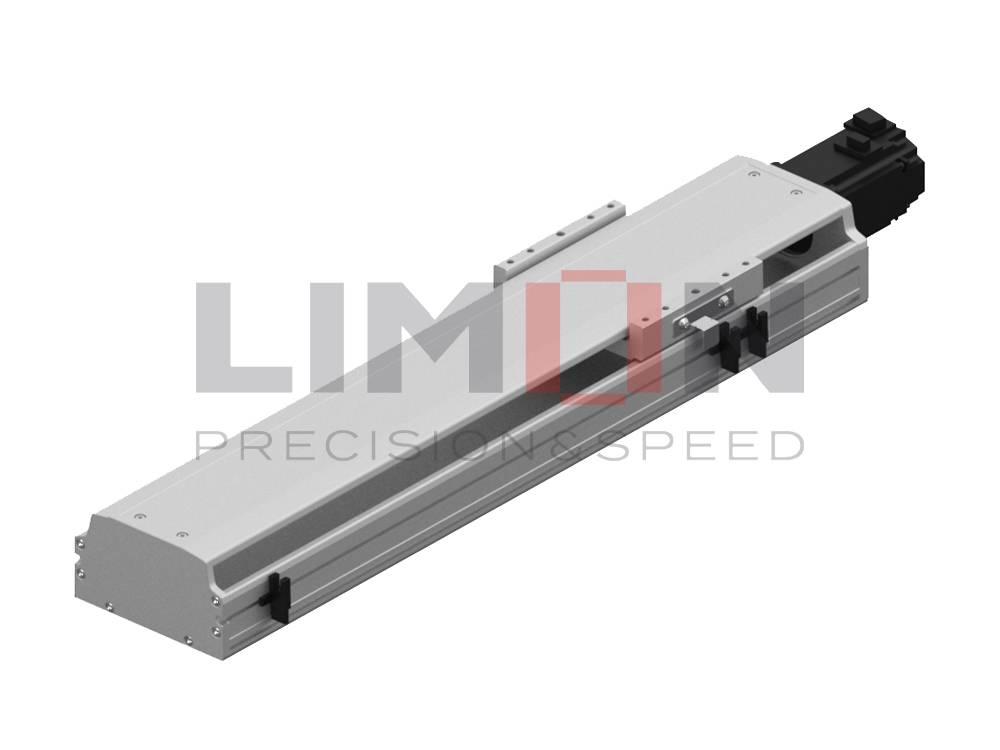

The positioning accuracy is ±0.05mm, maximum speed 5m/s. - Ball screw driven type linear module

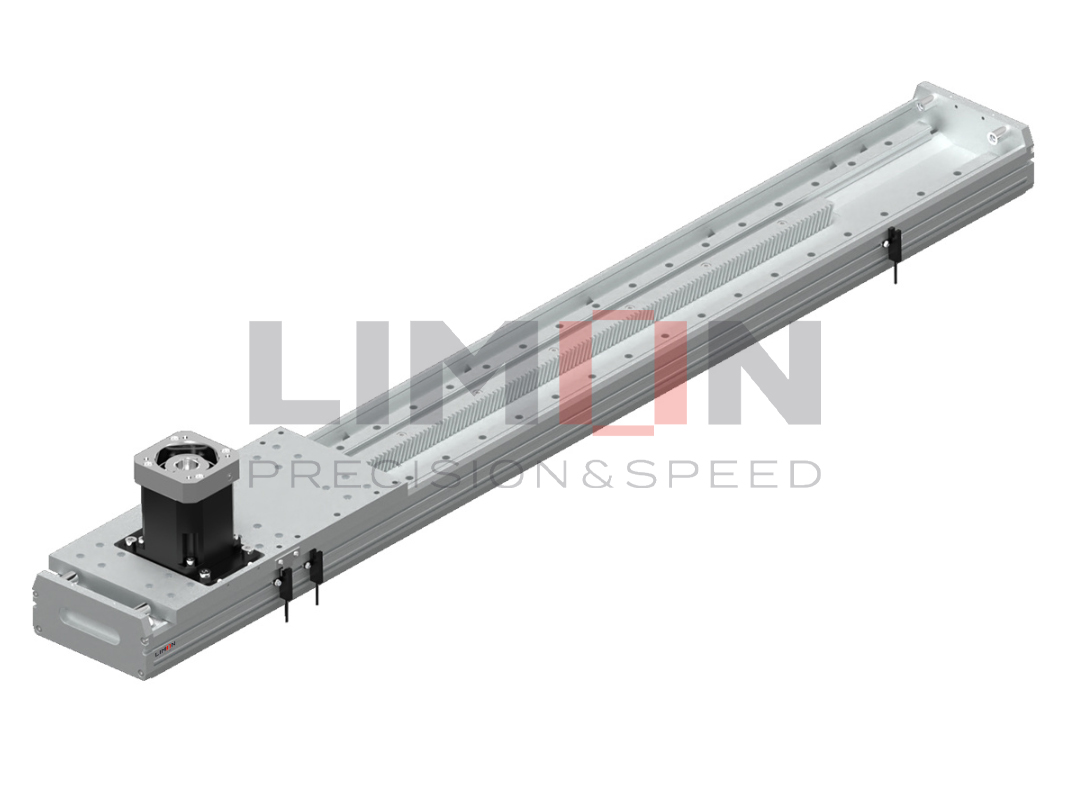

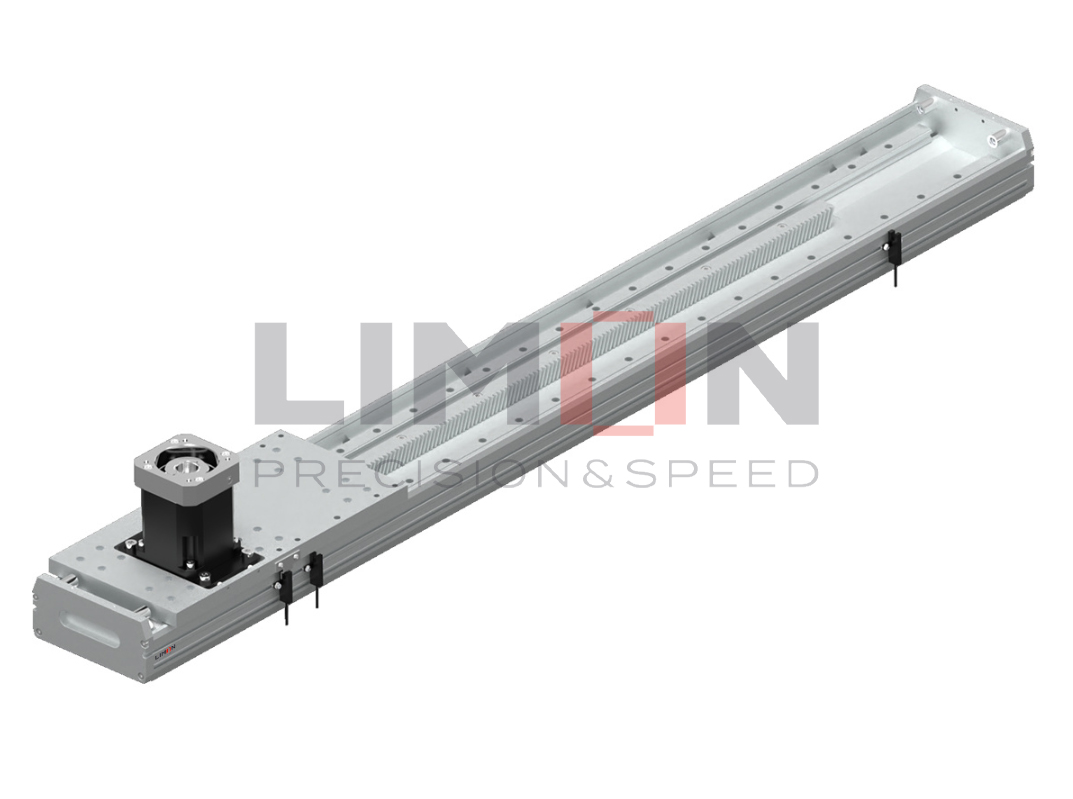

The positioning accuracy is ±0.01mm, maximum speed 1m/s. - Linear motor driven type linear module

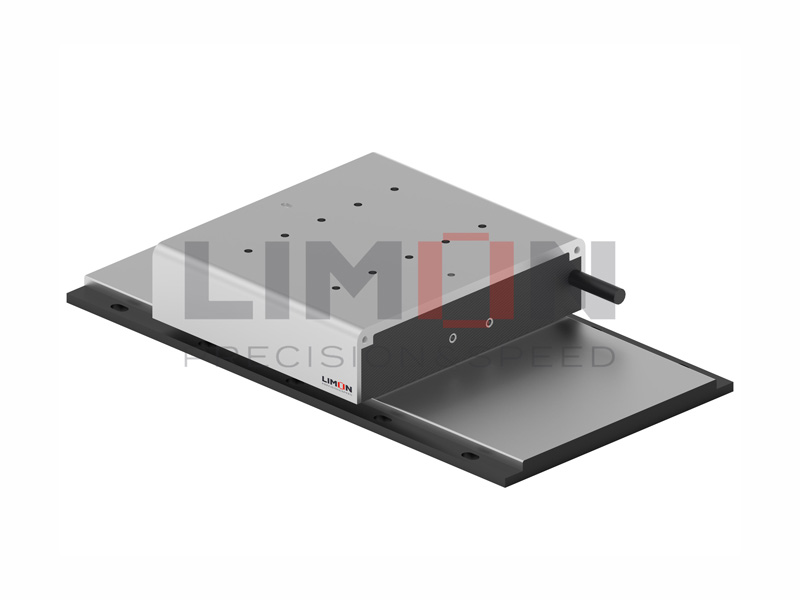

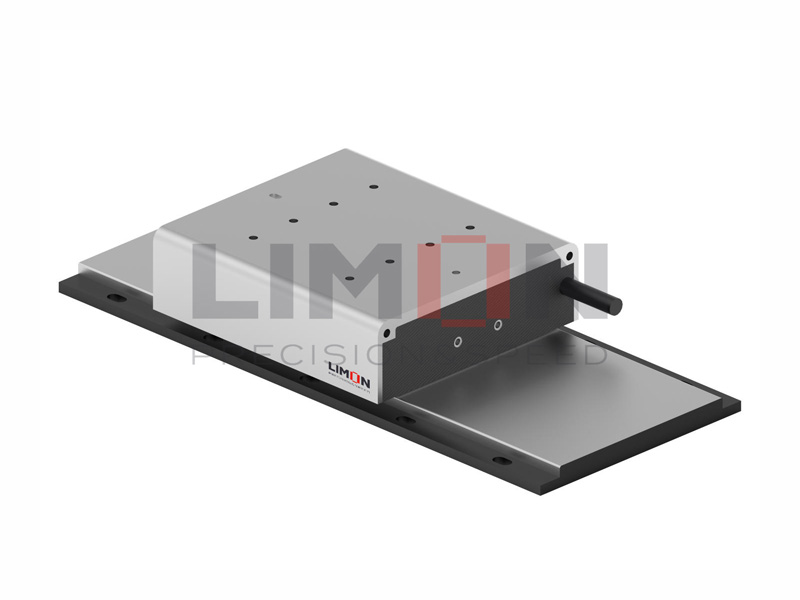

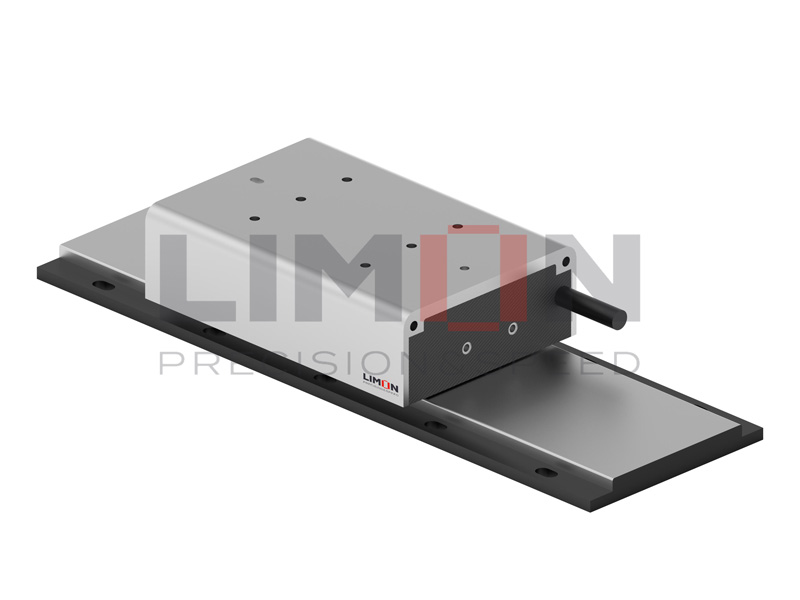

Linear Module

Linear Module

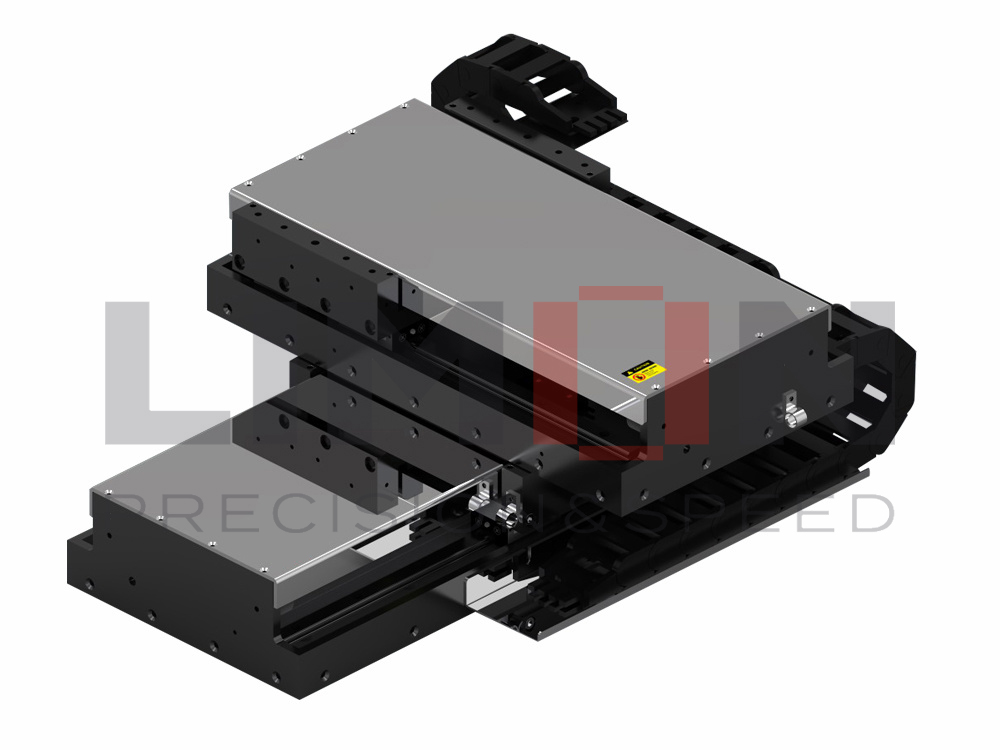

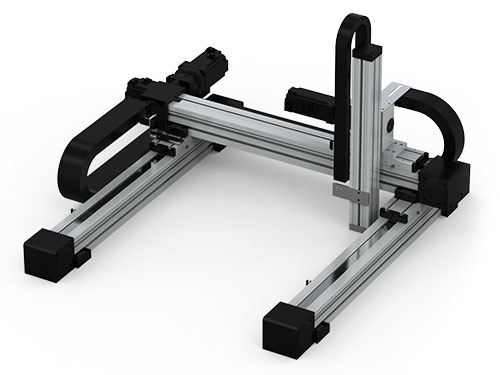

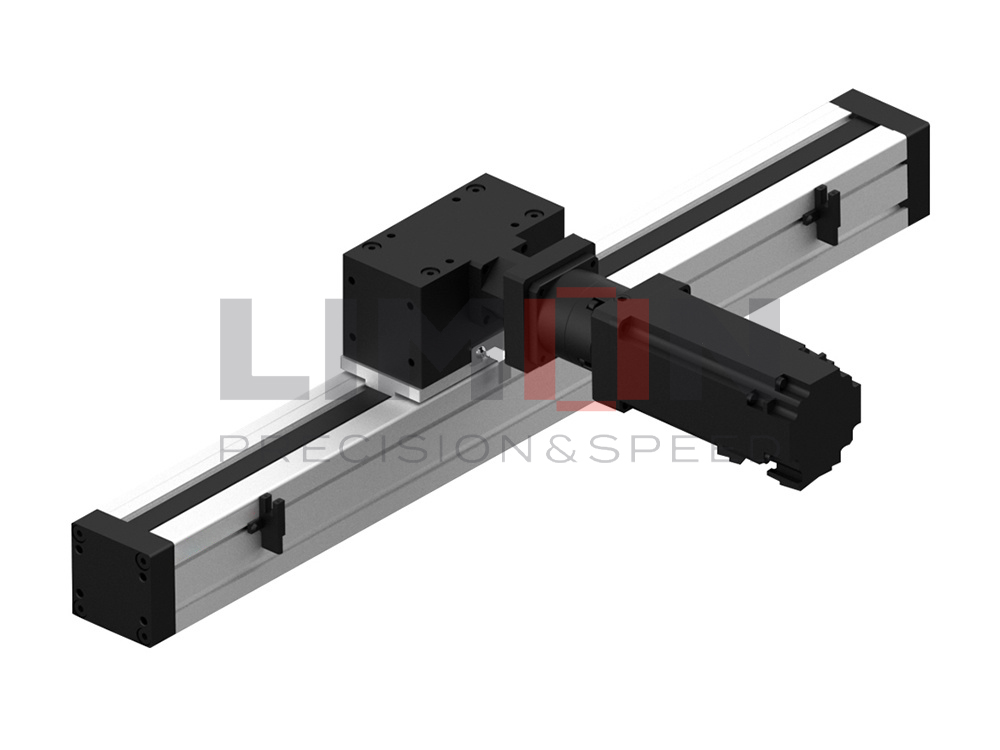

The linear module is a mechanical structure that provides linear motion. It can be used horizontally or vertically. It can also be combined into a specific motion mechanism–that is, multi-axis motion commonly referred to as XY axis, XYZ axis, etc. in the automation industry mechanism.

LIMON linear module is usually used with a power motor. It can be used to automatically reciprocate the work piece by installing other required work pieces on the block to form a complete conveying motion device and setting a suitable motor forward and reverse program. Thereby achieving the purpose of mass production and intensive production of equipment.

Our company’s linear module products are widely used in automated production equipment, dispensing, painting, picking and placing.

What are the main types of linear module?

Characteristics

- Belt, ball screw and linear motor driven type

- Max.Stroke 12 meters for belt type and 1.5 meters for ball screw type.

- Clean room protection class 10

- Customized solution

- High speed

- High precision

- Components available

- Both close and open type for different working environment are available

- Wide product range for all the applications

- All options for the simple assembly of multi-axis systems

What is the difference between repeatability and accuracy of these three types linear module?

- Belt driven type linear module (±0.05)

- Ball screw driven type linear module(±0.01)

- Linear motor driven type linear module(±0.001)

Technical Blogs

Knowleage

How does the linear module works?

The name of linear module is also varied, including linear unit, electric cylinder, slide table and mechanical arm. Although the name is different, its working principle is the same.

It can be divided into belt driven, ball screw driven type and linear motor driven type, and the working principle of first two are the same. They are the modular product which integrates servo motor, screw and timing belt, which convert the servo motor rotation movement into linear motion, at the same time, convert the best advantage of servo motor: speed control precision, precise control of speed, revolution and torque into precise speed, position and thrust control of the actuator, and finally achieve high-precision linear motion. For linear motor driven type, it converts electric energy into linear motion mechanical energy without any intermediate conversion mechanism.

What is the difference between repeatability and accuracy of these three types linear module?

- Belt driven type linear module (±0.05)

- Ball screw driven type linear module(±0.01)

- Linear motor driven type linear module(±0.001)

What is a linear module used for?

Linear modules combine highly sophisticated movements with high rigidity. They can be easily installed and are generally designed for average loads. In contrast, linear stages are especially suitable for moment loads due to the structure of the guide system. The various motorised versions can be used in many sectors of conveyor technology and automation.

Packaging industry–Linear modules have long time used in packaging applications, in this industry flexibility is the most important thing and in this parts linear modules can provide a reliable solution for pick and packing.

Automotive industry–Linear module high precision makes popular used in pressure machine, test instruments, etc.

Automation Industry–Food machinery, ceramic machinery, welding machinery, spraying equipment, lifting platform, etc

Military industry–Linear module it’s high precision can used for simulation aircraft, simulation, etc.

Coating industry–Automatic spraying machine, Automatic book machine, Automatic dispensing machine.

3C industry–Mobile phone dispensing, testing.

LCD panel industry–Handling and transplanting of LCD panel, testing.

Food industry–Food packing, and handling.

LIMON always concentrate on enriching the value of our products for our customers, we have the ability to design and also can provide customized solutions. Our engineering team is rich experienced, we have the ability to design and also customized solutions. We are committed to supply more efficient and satisfied cases to the clients. Before sales, by using LIMON calculate system and considering the risk analysis, our engineers will choose the most safe, and cost-effective type for our customers.

We have been working with our Taiwan engineers since 2012. Both ball screw driven type and belt driven type are designed to be very flexible with multiple components ability, it is easy to assemble.

Stronger, faster, and able to support more weight than competing choices, LIMON’s extremely efficient electric cylinder type linear actuators were conceived to save space, save energy, save time, and save labor costs.

s.jpg)