In the world of industrial automation and mechanical design, choosing the right type of bushing is crucial for performance, reliability, and maintenance strategy. Whether you’re building a CNC machine or optimizing equipment for how to fulfill dropshipping orders on Shopify, understanding the differences between linear bushings and oil-free bushings will steer you toward smarter decisions.

1. Lubrication Requirements

Linear Bushing

Requires external lubrication (oil or grease).

Essential for reducing friction and extending lifespan.

Ideal for high-speed, precision-based applications like robotics and factory automation.

Oil-Free Bushing

Self-lubricating: made with embedded solid lubricants like graphite or PTFE.

No need for external lubrication — a major plus in environments where maintenance is a challenge.

Especially useful in packaging lines, food-grade machinery, or environments involving dust and debris.

2. Structure & Material Composition

Linear Bushing Construction

Made of steel or engineered plastic housings.

Contains multiple recirculating ball bearings for ultra-smooth linear motion along a shaft.

Designed for applications requiring high precision and low friction.

Oil-Free Bushing Construction

Built from sintered bronze, composites, or engineered polymers.

Internal solid lubricants eliminate the need for routine oiling.

Offers quiet operation and long life, even under challenging conditions.

3. Applications & Ideal Use Cases

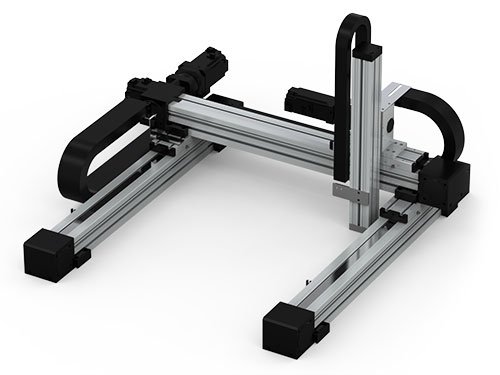

Where Linear Bushings Shine

CNC machinery

3D printers

Medical automation

Robotics

Assembly lines that require high-speed linear motion

These are also common in modern e-commerce fulfillment systems — particularly in automated solutions for how to fulfill dropshipping orders on Shopify, where precision and repeatability matter.

Where Oil-Free Bushings Win

Food & beverage equipment

Cleanrooms

Outdoor or dusty environments

High-temperature systems

Areas with restricted access for maintenance

They’re a favorite in “set-and-forget” machinery that just needs to run — no lube, no fuss.

4. Maintenance Requirements

Linear Bushings

Require regular maintenance and periodic relubrication.

Can deliver top performance but demand attention over time.

Oil-Free Bushings

Zero maintenance.

Perfect for companies that value uptime over tinkering.

Fewer moving parts, fewer headaches.

Materials Used in Linear Bushings

Choosing the right material isn’t just about durability — it’s about aligning with your application, budget, and environmental constraints.

Bearing Steel (e.g., SUJ2, 52100 Steel)

Excellent wear resistance

Ideal for high-load, high-speed operations

Requires lubrication

Stainless Steel (e.g., SUS440C, SUS304)

Corrosion-resistant

Perfect for cleanrooms, medical, or food-grade environments

Bronze (e.g., Sintered Bronze, Phosphor Bronze)

Common in oil-free bushing designs

Infused with solid lubricants for self-lubricating properties

Engineering Plastics (PTFE, POM, PA, UHMW-PE)

Lightweight, chemical-resistant, and maintenance-free

Great for applications with limited load or in corrosive conditions

Composite Materials (PTFE-coated metals, fiber-reinforced polymers)

Combine the strength of metals with the low friction of polymers

Long service life and ideal for harsh or high-load applications

Final Takeaway

The right bushing for your project depends on what you value most — precision, maintenance-free performance, or resilience in extreme environments.

Choose linear bushings when precision linear motion and high-speed operation are your top priorities.

Choose oil-free bushings when maintenance-free performance in harsh or sensitive environments is critical.