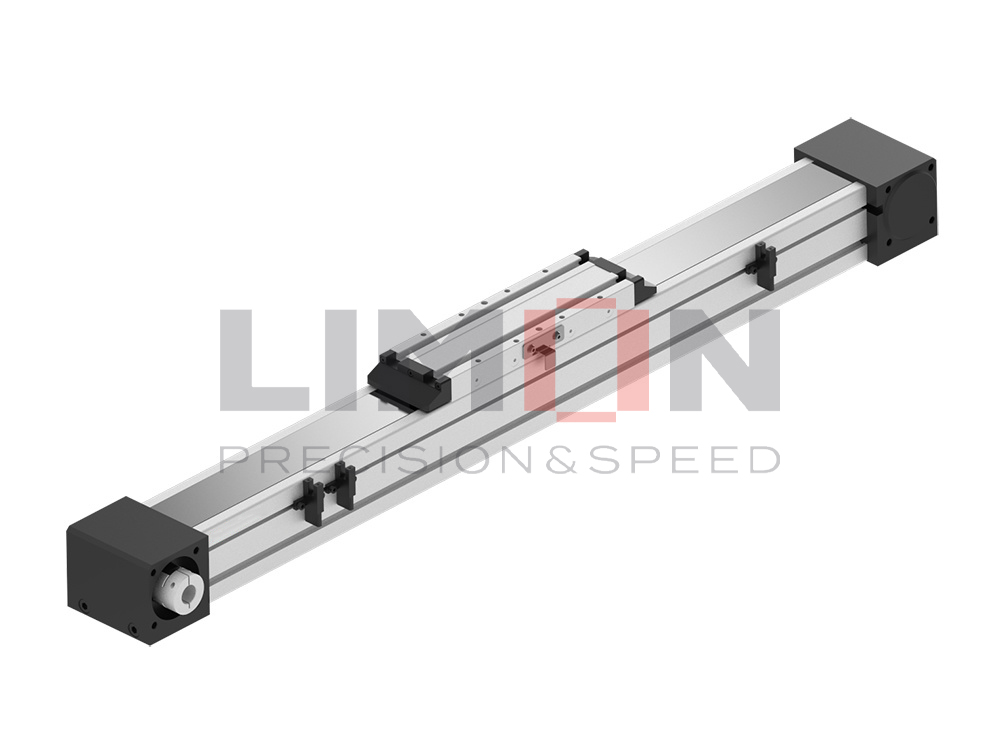

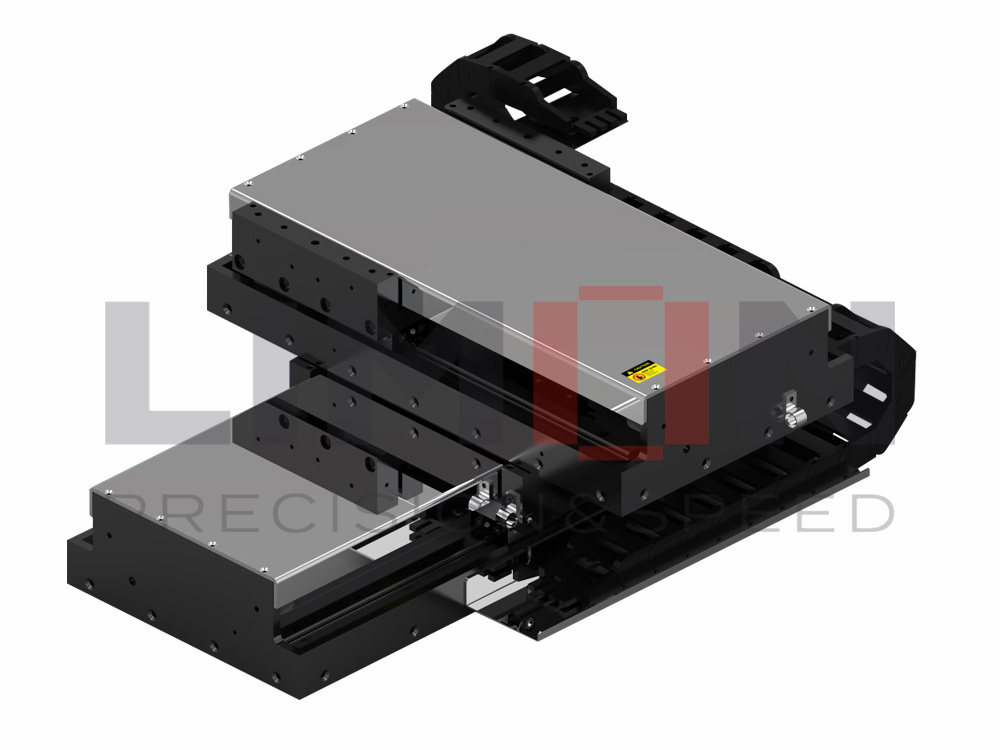

Linear guideways play a fundamental role in ensuring the accuracy and repeatability required in the manufacturing of precision instruments. Their ability to maintain exact positioning with minimal deviation is crucial for applications such as semiconductor production, laboratory equipment, and medical devices. The integration of high-precision linear guideways enhances the overall performance and reliability of intricate machinery.

How Does the Low-Friction Characteristic Improve the Operating Efficiency and Service Life of Linear Guideways?

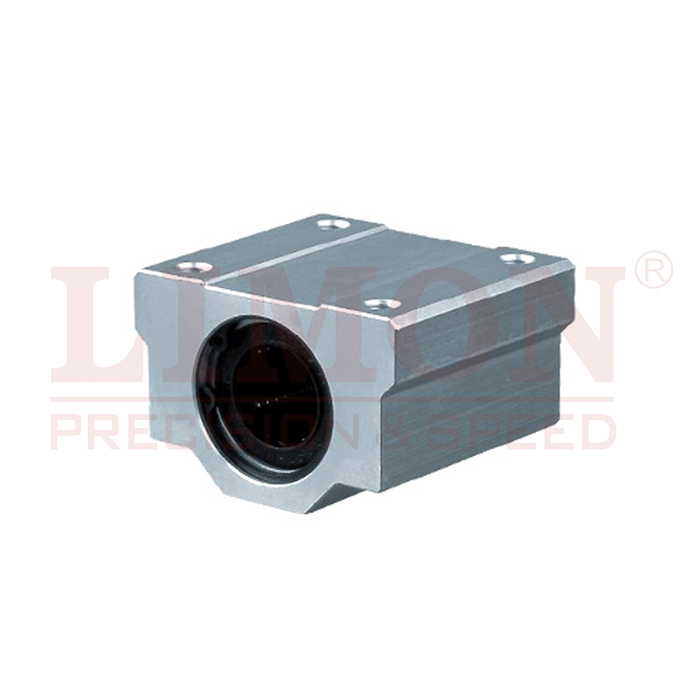

The low-friction characteristic of linear guideways minimizes resistance, reducing wear and tear while enhancing energy efficiency. This results in smoother motion, increased precision, and extended operational lifespan. By decreasing mechanical stress, these components improve overall system efficiency, ensuring long-term performance in high-demand applications such as automation, CNC machinery, and robotics.

Conclusion

Precision and low-friction linear guideways enhance efficiency, durability, and reliability in precision instrument manufacturing, ensuring optimal performance and longevity.