In precision-driven industries like automation, CNC machining, and robotics, the linear bushing plays a critical role in enabling smooth, controlled linear motion. From improving mechanical efficiency to extending equipment lifespan, understanding the value of linear bushings can make or break your engineering decision-making — especially in systems handling complex workflows like how to fulfill dropshipping orders on Shopify.

What Is a Linear Bushing Used For?

A linear bushing is designed to provide low-friction linear motion along a hardened shaft. It’s most commonly used in:

Industrial automation systems

CNC machines

3D printers

Robotic arms

E-commerce fulfillment machinery (including Shopify-based setups)

These components enable precise movement, reduce mechanical wear, and improve overall system performance.

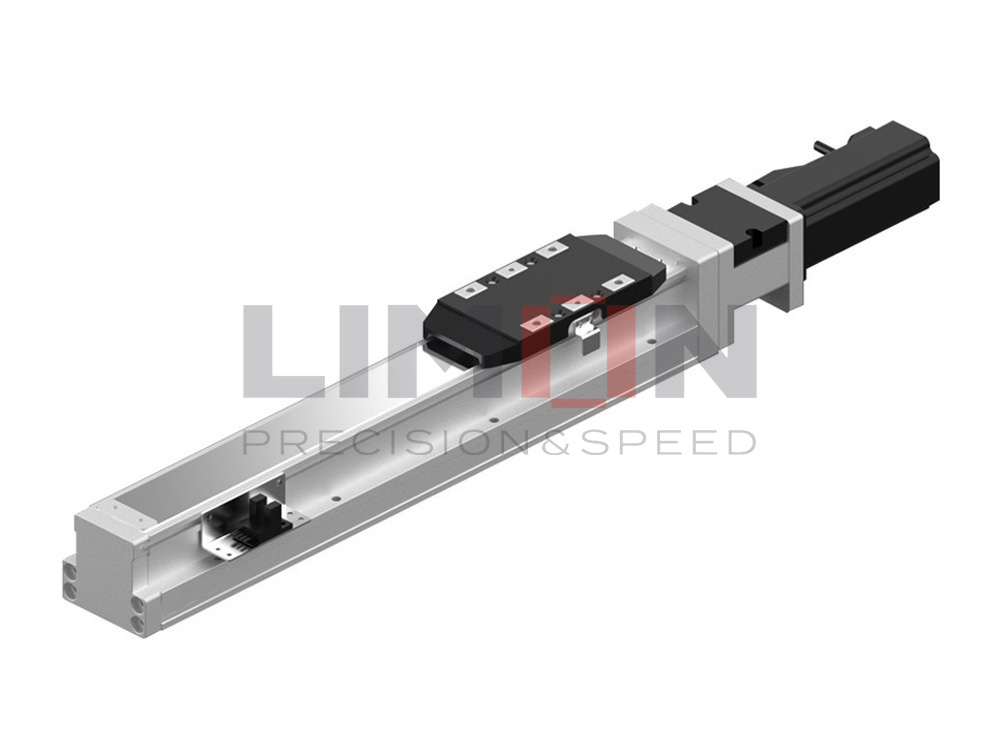

How Does a Linear Bushing Work?

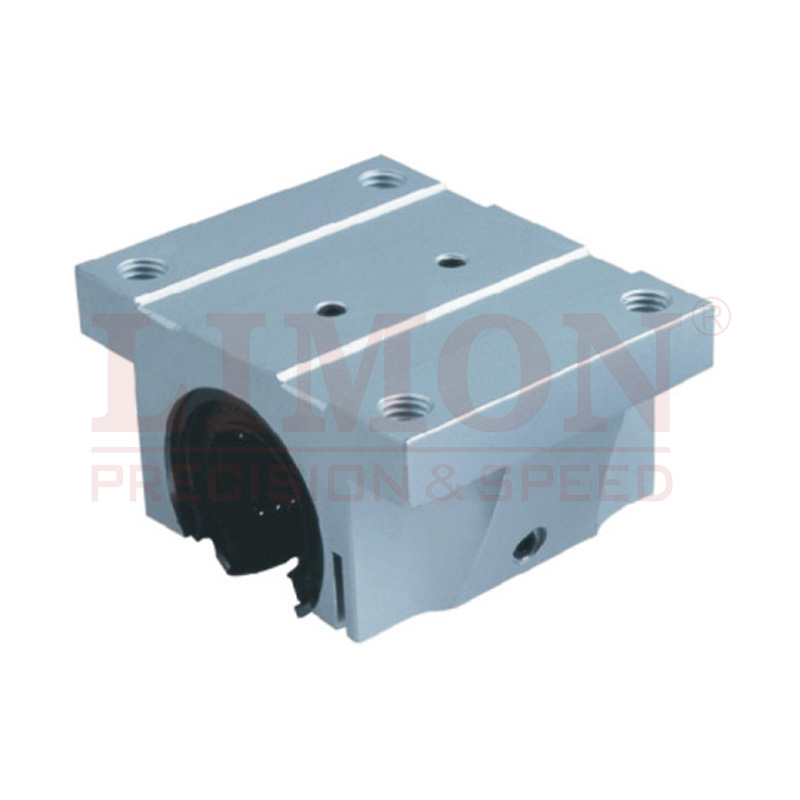

A linear bushing functions by incorporating rolling elements—typically ball bearings—inside a cylindrical housing. These elements circulate within the bushing to create smooth, guided linear motion. The structure generally includes:

An outer cylinder (usually steel or polymer)

Ball retainers to manage bearing circulation

A shaft interface for low-friction glide

This system minimizes friction and ensures high-accuracy motion, critical in applications where every micron matters—like the automation of how to fulfill dropshipping orders on Shopify.

What Is the Purpose of a Bushing?

At its core, a bushing:

Supports and guides linear motion

Reduces metal-to-metal contact

Minimizes wear and vibration

Extends component lifespan

It acts as a protective interface between the moving part and the shaft, ensuring stable, repeatable performance over time.

Linear Rod Bearings vs. Bushings: What’s the Difference?

While both components support linear motion, there are key differences:

| Feature | Linear Rod Bearing | Linear Bushing |

|---|---|---|

| Motion | Rolling | Sliding or rolling |

| Friction | Very low | Low |

| Speed Suitability | High-speed | Medium to high |

| Maintenance | Requires lubrication | May be oil-free |

| Ideal Usage | CNC, robotics | General automation, high load |

Linear rod bearings are optimized for precision and speed, while oil-free bushings may be better suited for harsh or lubrication-limited environments.

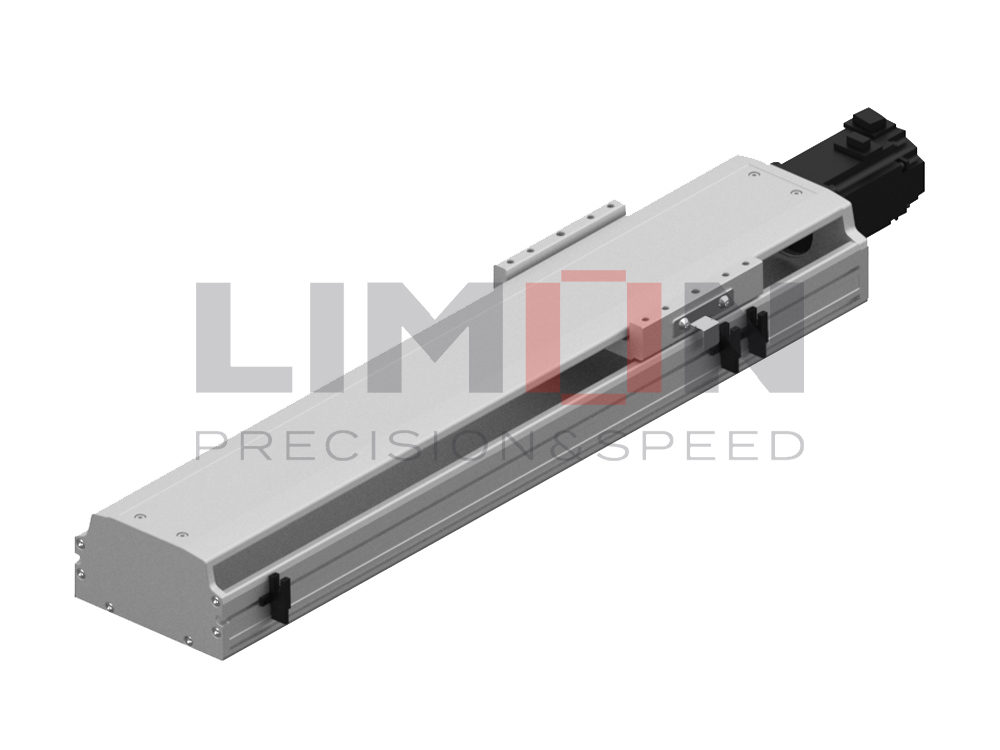

Key Advantages of Linear Bushings

Why are linear bushings so widely used? Here’s what they bring to the table:

Reduced Friction: Ball bearings lower resistance, boosting performance

High Precision: Perfect for repeatable linear movement in automation

Robust Load Capacity: Supports axial and radial loads

Durability: Withstands rugged conditions with minimal degradation

Versatility: Fits a wide range of industrial applications

These benefits are crucial for maintaining uptime in systems engineered for tasks like how to fulfill dropshipping orders on Shopify, where accuracy and efficiency must scale with demand.

Can You Replace Bushings Yourself?

Yes — and with the right tools and process, it’s straightforward.

Step-by-Step Bushing Replacement:

Identify the Right Bushing: Match size, type, and material specs.

Remove the Worn Component: Carefully extract the old bushing without damaging the shaft.

Clean the Shaft: Eliminate debris and residue.

Install the New Bushing: Align and insert gently.

Test for Smooth Operation: Move the shaft to check for friction or play.

Proper maintenance ensures your system runs smoothly — a must in lean setups like dropshipping fulfillment workflows.

Final Thoughts: The Strategic Role of Linear Bushings

From precision manufacturing to e-commerce logistics, the linear bushing remains a cornerstone of modern mechanical design. Its ability to provide frictionless linear motion, increase equipment life, and maintain system accuracy makes it indispensable — especially in industries seeking to automate critical processes like how to fulfill dropshipping orders on Shopify.