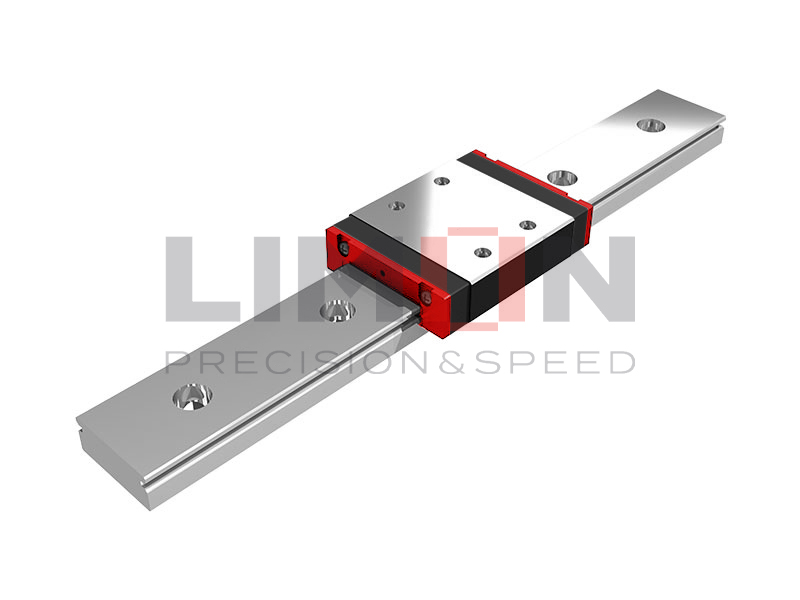

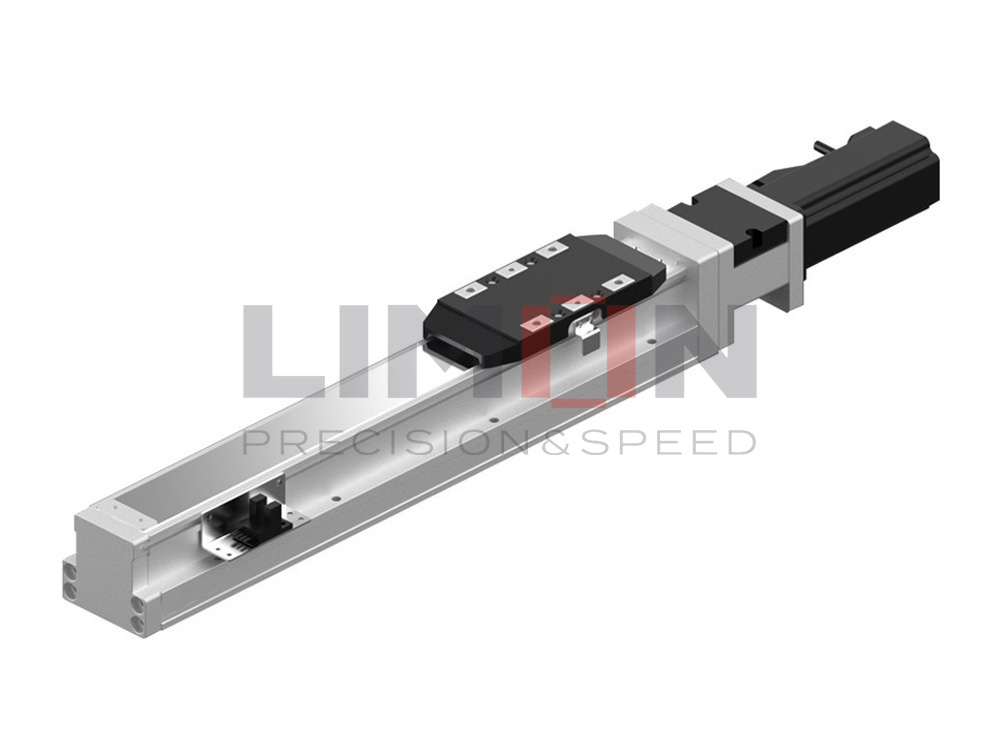

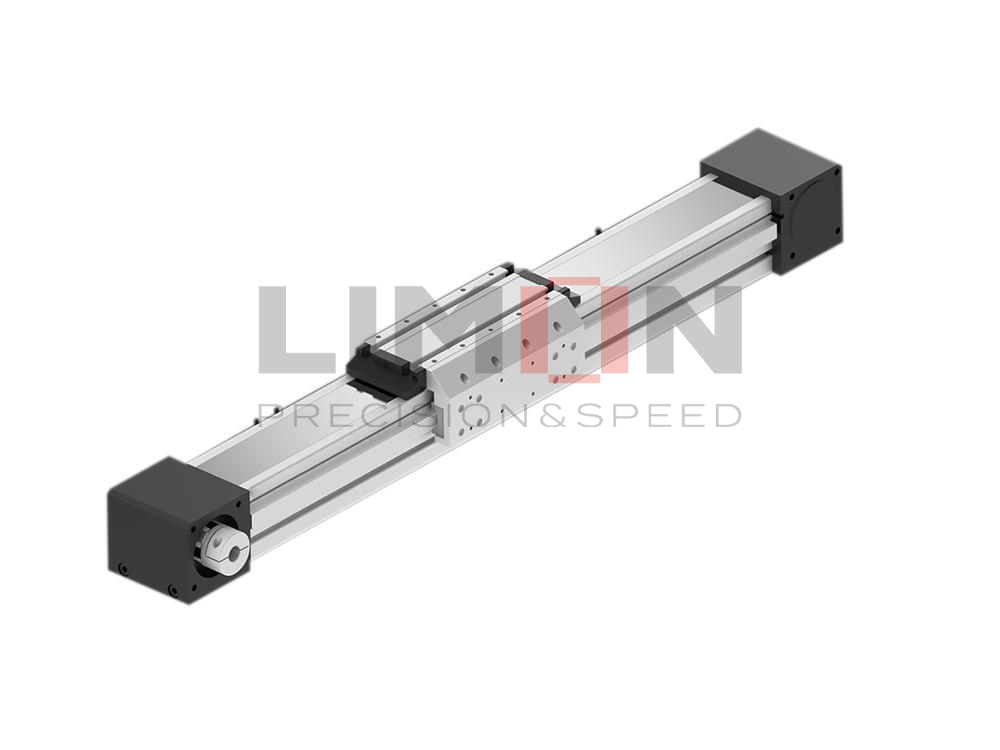

A ball screw linear actuator is a high-precision motion control device that transforms rotational motion into linear motion using a ball screw mechanism. Compared to traditional lead screw systems, this actuator delivers exceptional efficiency, positioning accuracy, and durability—making it a go-to solution for automation systems, robotics, and CNC machinery.

Why Use a Ball Screw Linear Actuator?

If your application demands high precision, low backlash, and consistent repeatability, a ball screw linear actuator is the smart investment. Its screw-driven design minimizes friction, enhances rigidity, and offers superior load-handling capability—far outperforming belt-driven alternatives in critical industrial environments.

Key Advantages of Ball Screw Linear Actuators

High Precision and Accuracy

The ball screw mechanism delivers micron-level accuracy with minimal backlash. Perfect for semiconductor equipment, CNC machining, and any system requiring ultra-precise positioning.

Efficiency and Low Friction

By using rolling ball bearings, friction is drastically reduced, resulting in higher mechanical efficiency and lower operational power consumption compared to lead screws.

High Load-Bearing Capacity

Designed for industrial-grade performance, ball screw linear actuators can handle heavy loads with stability—making them ideal for machining centers, robotic arms, and automated material handling systems.

Smooth and Consistent Motion

The ball bearing interface ensures quiet, smooth, and vibration-free movement—essential for high-speed automation and robotic systems where precision is non-negotiable.

Extended Service Life

Thanks to the low-friction rolling action, ball screw actuators offer a longer lifespan when properly lubricated and maintained, reducing your total cost of ownership.

Superior Rigidity and Stability

With a robust screw-driven structure, these actuators resist deflection under heavy loads, delivering stable and reliable motion across long travel lengths.

Common Applications of Ball Screw Linear Actuators

Ball screw linear actuators are widely implemented across mission-critical sectors:

CNC Machining – For ultra-precise control in milling, drilling, and routing.

Industrial Automation – From pick-and-place systems to robotic arms, enabling accurate positioning.

Medical Equipment – Ensuring micro-level control in imaging and surgical systems.

Semiconductor Manufacturing – Providing cleanroom-compatible, high-resolution motion.

Aerospace & Automotive – Supporting dynamic testing and component prototyping with reliable motion control.

Conclusion

For industries that rely on precision, efficiency, and high-duty performance, a ball screw linear actuator is the clear winner. Whether you’re upgrading an existing system or designing a new solution, integrating ball screw technology into your linear motion platform will deliver unmatched results in speed, accuracy, and reliability.