In the world of precision motion control, the ball screw linear actuator is the go-to hero—delivering accuracy, efficiency, and reliability where it matters most. From CNC machinery to surgical robotics, this screw-driven marvel transforms rotary motion into flawless linear movement.

Let’s break down exactly why engineers swear by it.

What Is a Ball Screw Linear Actuator?

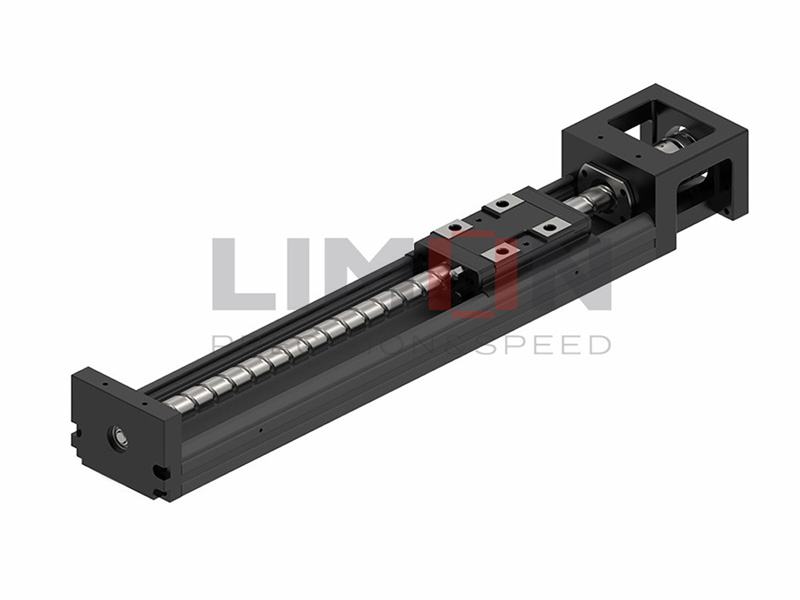

A ball screw linear actuator is a mechanical motion system that converts rotary motion into linear displacement via a ball screw mechanism. Engineered for high-precision and repeatable performance, it’s a staple in automation, semiconductor manufacturing, and advanced robotics.

Key Features of a Ball Screw Linear Actuator

High Precision and Accuracy

Thanks to its rolling ball interface, the ball screw linear actuator drastically reduces friction and eliminates backlash.

Perfect for tasks demanding sub-micron accuracy.

Common in semiconductor, medical device, and robotics industries.

It’s the difference between “close enough” and “flawless.”

High Efficiency and Low Friction

Compared to lead screw systems, a ball screw linear actuator offers:

Up to 90% mechanical efficiency

Smooth motion even under high loads

Lower energy consumption and operational cost

When every kilowatt counts, friction becomes your enemy—and this actuator is your shield.

Excellent Load-Bearing Capacity

The ball screw linear actuator handles heavy loads without sacrificing precision.

Even load distribution prevents localized wear

Ideal for CNC machines, injection molders, and automated production lines

It’s the bouncer at your automation club—strong, precise, and reliable.

Long Service Life and Durability

Because it relies on rolling rather than sliding, the ball screw linear actuator offers:

Lower wear and tear

Reduced maintenance intervals

Extended operational life

Think of it as the Swiss watch of actuators—built to last, engineered to perform.

Versatility in Industrial Applications

Whether you’re positioning a medical scanner or aligning a robotic welder, the ball screw linear actuator adapts with grace:

Used in electronics assembly, diagnostics, aerospace systems, and more

Easily integrates into complex automation frameworks

It’s your one-size-fits-all solution for precision motion control.

Conclusion: Why Choose a Ball Screw Linear Actuator?

If your business runs on precision and uptime, the choice is clear:

The ball screw linear actuator delivers superior accuracy, high load capacity, and low-maintenance durability. Its screw-driven architecture ensures efficient, reliable performance across mission-critical operations.

Whether you’re building the next-gen robotic assembly line or fine-tuning medical automation, this actuator doesn’t just perform—it elevates your entire system.

Ready to upgrade your motion system?

Let’s talk about how a ball screw linear actuator can optimize your industrial setup. Precision is no longer optional—it’s your competitive edge.

.