Misaligned or unstable motion systems cause breakdowns, accuracy loss, and reduced machine life. Linear rails offer a reliable, precise solution for guiding heavy loads in straight-line motion.

Linear rails are mechanical components that guide linear motion with high accuracy and rigidity. Available in various types, they enhance efficiency in CNC machines, automation lines, and medical devices.

Continue reading to explore types, principles, and real-world uses.

Understanding the Fundamental Principle of Linear Rails

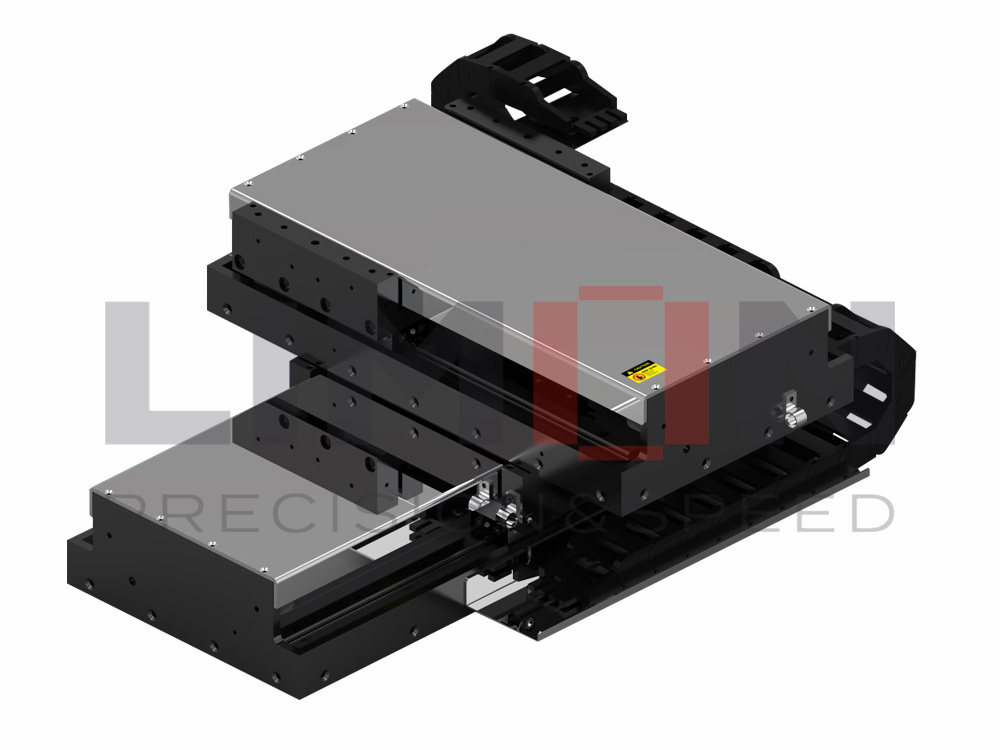

Linear rails (also called linear guideways or linear motion guides) are systems designed to guide movement along a straight line with minimal friction. They consist of two main components: a rail and a block (or carriage) that slides along the rail. Inside the block, recirculating ball or roller elements help distribute load and ensure smooth, precise motion.

The working principle is based on rolling contact. Unlike plain sliding, the rolling mechanism—either balls or rollers—reduces resistance dramatically. This allows for:

Smooth, high-speed motion

Accurate positioning

High load-bearing capacity

Long operational life

Preloaded designs reduce play (backlash), and integrated seals protect internal components from dust and debris. This makes linear rails ideal for repeatable positioning in demanding industrial conditions.

What Are the Different Types of Linear Rails?

There are several types of linear rails, each optimized for specific load conditions, environments, and precision requirements.

1. Profiled Rail Guides (Linear Guideways)

These are the most common type in precision machinery. They consist of a rail with a defined groove shape and a matching block containing recirculating ball bearings.

Key benefits:

High rigidity

High precision

Excellent load capacity in all directions

Used in: CNC machines, 3D printers, semiconductor tools

2. Round Shaft Linear Rails

These use a cylindrical rail and a bushing-style bearing that slides or rolls along it. They are easier to mount and more tolerant to misalignment.

Key benefits:

Low cost

Easy to align

Moderate accuracy

Used in: Packaging machines, material transport, low-cost automation

3. Roller-Type Linear Rails

Instead of balls, these rails use cylindrical rollers inside the block, offering more contact area and higher load support.

Key benefits:

Increased load rating

Enhanced rigidity under vibration

Used in: Heavy machinery, press tools, automotive production lines

4. Miniature Linear Rails

Compact versions of profiled rails used where space is limited.

Key benefits:

Space-saving

Precision movement in tight configurations

Used in: Lab automation, optics systems, micro-machines

Comparison Table: Types of Linear Rails

| Type | Structure | Key Benefits | Typical Applications |

|---|---|---|---|

| Profiled Rail Guides | Rectangular rail + recirculating ball block | High rigidity, precision, load in all directions | CNC machines, 3D printers, automation systems |

| Round Shaft Rails | Cylindrical shaft + linear bushing | Easy alignment, affordable, good for moderate precision | Packaging lines, light-duty equipment |

| Roller-Type Rails | Rectangular rail + roller-bearing block | Very high load capacity, vibration-resistant | Automotive, presses, heavy machinery |

| Miniature Linear Rails | Compact profiled rail + small block | Space-saving, accurate micro-movement | Optical instruments, lab automation, electronics |

Each rail type serves different mechanical needs—proper selection depends on the environment, load profile, speed, and alignment tolerance.

What Are the Applications and Benefits of Linear Rails?

Linear rails are vital in any machine where accurate linear positioning is essential. They enable systems to move with speed and precision, supporting static or dynamic loads.

Key Applications:

CNC Machinery: Enables precise tool paths on X, Y, and Z axes

Robotics: Supports actuators, end effectors, and collaborative arms

Medical Equipment: Assists in imaging devices and patient transport systems

3D Printing: Guides printer heads with high-resolution accuracy

Assembly Lines: Ensures consistent part placement in automated systems

Benefits of Linear Rails:

High Load Capacity: Rails distribute load evenly, minimizing wear

Low Friction: Reduces motor effort and energy usage

Durability: Hardened steel rails with proper lubrication last thousands of hours

High Repeatability: Ideal for repetitive operations requiring consistency

Compact Design: Offers strong performance in small spaces

Reduced Maintenance: Pre-lubricated, sealed units require minimal upkeep

By using linear rails, manufacturers achieve more reliable, quiet, and efficient motion, boosting productivity while reducing machine fatigue and alignment issues.

Summary

Linear rails deliver smooth, precise motion—making them essential for efficient, accurate, and durable machine design across modern industries.For further questions please contact [email protected]