What Are Ball Screws, and Why Are They Essential?

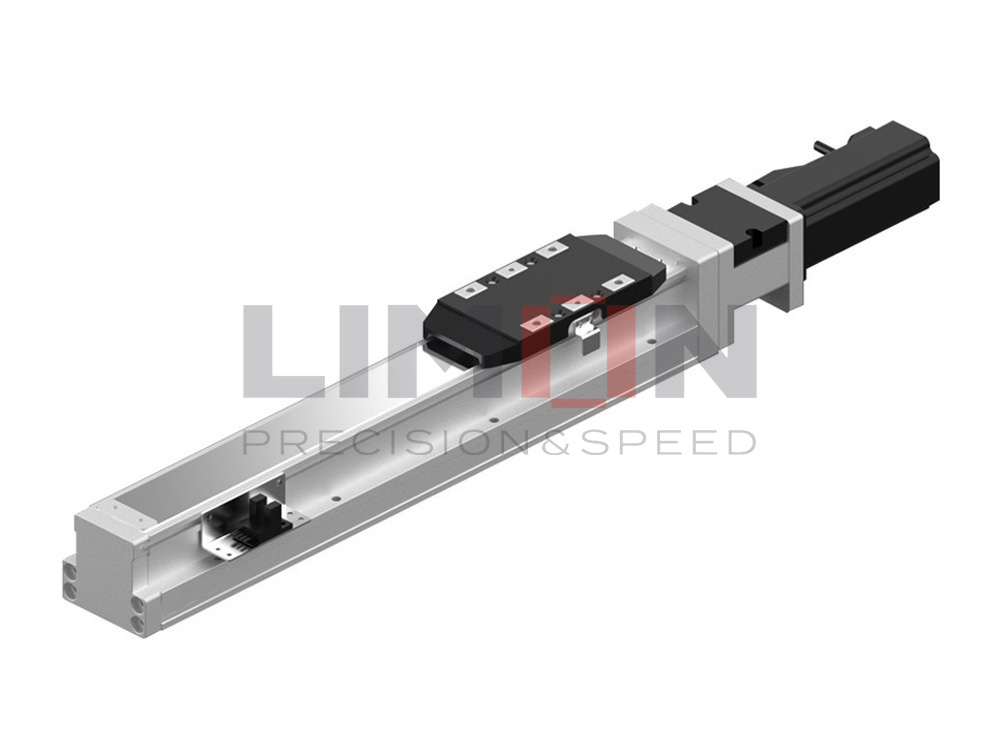

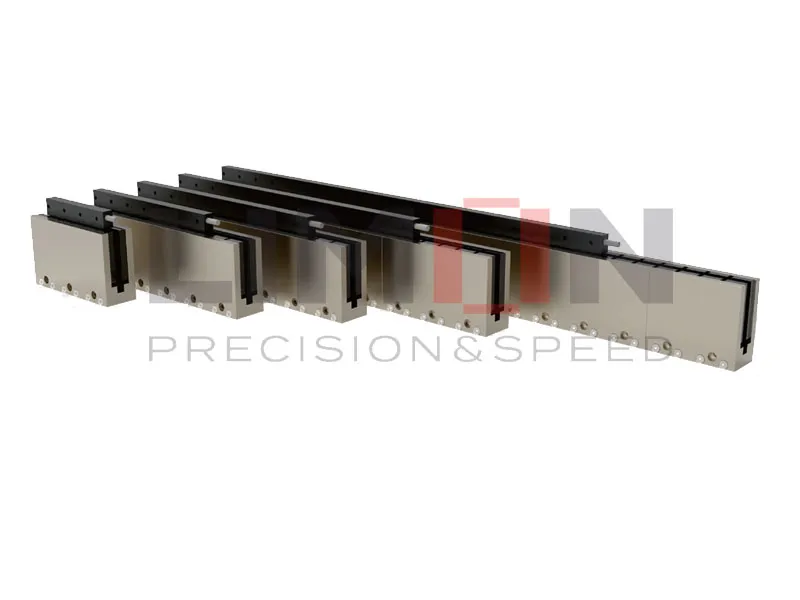

Before diving into the benefits, let’s clarify: what exactly are ball screws? They’re mechanical devices designed to convert rotary motion into linear motion with high efficiency and precision. Compared to lead screws, ball screws stand out for their reduced friction and superior load-bearing capacity.

For a detailed comparison between ball screws and lead screws, check out this guide.

Precision Redefined with Ball Screws

In industries where accuracy defines success, ball screws deliver unparalleled performance. Their low backlash and consistent motion control make them ideal for applications like:

- CNC machining

- Robotics

- Medical equipment

Imagine running a CNC machine where every cut matches your exact specifications. With ball screws, that level of precision isn’t just possible—it’s guaranteed.

Energy Efficiency That Drives Savings

Efficiency is a game-changer, especially when operating high-speed automation systems. Ball screws use rolling elements (ball bearings) instead of sliding friction, leading to:

- Smoother motion

- Lower energy consumption

- Reduced heat generation

This efficiency not only enhances performance but also significantly reduces energy costs over time.

Need proof? Learn more about how energy-efficient ball screws improve manufacturing processes on this blog.

Built to Last: Durability of Ball Screws

Industrial environments are tough, and equipment downtime can cost you more than just money. Thankfully, ball screws are designed for longevity. Their hardened surfaces and robust construction ensure:

- Resistance to wear and tear

- Performance consistency under high loads

- Longer service life

Regular maintenance is key, though. Here’s a step-by-step maintenance guide for ball screws.

Versatility Across Industries

One of the most attractive benefits of ball screws is their adaptability. No matter your industry, ball screws fit the bill. They’re commonly used in:

- Aerospace for precise component positioning

- Automotive assembly lines for high-load applications

- Robotics for smooth, precise movements

This versatility makes ball screws a universal solution for businesses aiming to improve efficiency and accuracy.

Are Ball Screws Cost-Effective? Absolutely!

While the initial investment in ball screws might seem steep, the long-term savings make them worth every penny. Here’s why:

- Lower maintenance costs

- Reduced downtime

- Energy efficiency leading to smaller utility bills

If you’re considering upgrading, read this article on calcuating ROI with ball screw.

Why Your Business Needs Ball Screws

If precision, efficiency, and durability are critical to your operations, ball screws are the upgrade your business needs. Over the years, I’ve seen companies transform their productivity by making this simple yet impactful change.

Take the Next Step with Ball Screws

Ready to optimize your industrial operations? Let’s connect and find the perfect ball screw solution for your business. Reach out today, or visit our product catalog to explore your options.