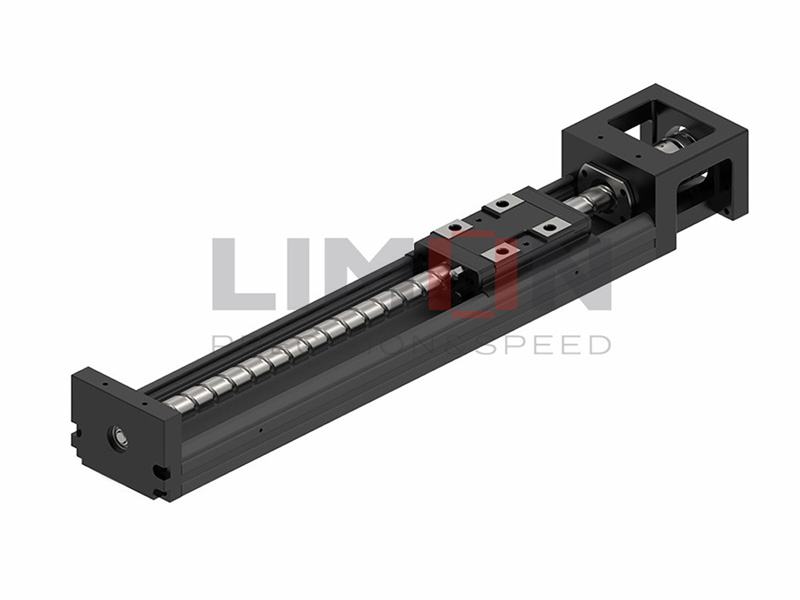

When it comes to motion control in industrial automation, rolling ball screws are the backbone of precision and repeatability. Whether you’re fine-tuning CNC machinery or building next-gen robotics, meeting strict precision standards is non-negotiable. Let’s break down the critical parameters that define a high-performance rolled lead screw.

Pitch Accuracy: The Core of Transmission Precision

The pitch accuracy of a rolling ball screw is the foundation of its positioning precision. It determines how consistently the nut moves per rotation.

Required tolerance: typically within ±0.001mm

Impact: Ensures high transmission accuracy and smooth linear motion

Industrial relevance: Critical in applications like CNC machining, medical devices, and semiconductor systems

Roundness Accuracy: Keeping the Cylindrical Form Perfect

Roundness accuracy refers to the deviation in the screw’s cylindrical surface. Although less critical than pitch, it still affects contact uniformity between the ball and raceway.

Standard requirement: within 0.002mm

Impact: Maintains consistent rolling performance and load distribution

Surface Roughness: The Finish That Drives Performance

A smooth surface is more than aesthetic—surface roughness directly affects friction, noise, and wear.

Optimal range: Ra0.8 to Ra1.6

Impact: Enhances transmission efficiency and extends service life

Straightness: The Spine of Precise Movement

Straightness defines how true the screw remains along its length. Even minor deviations can cause misalignment and binding.

Allowable tolerance: not exceeding 0.2mm over full length

Impact: Ensures smooth, low-friction linear movement

Hardness: Engineered for Wear and Corrosion Resistance

Hardness is crucial for wear resistance and long-term durability, especially in high-cycle environments.

Typical range: HRC58–HRC62

Impact: Supports high loads and resists surface fatigue

Tensile Strength: The Backbone of Load Capacity

A high tensile strength gives the rolled ball screw its ability to carry heavy loads without deformation.

Industry benchmark: ≥ 1900 N/mm²

Impact: Key factor in mechanical reliability and structural integrity

Fatigue Resistance: Built for the Long Haul

Fatigue resistance is the ability of a rolling screw to withstand repeated stress without failing.

Expected endurance: ≥ 10⁷ cycles

Impact: Critical for high-duty-cycle operations and automation

In precision engineering, a ball screw’s performance is only as good as its compliance with these standards. Whether you’re sourcing components or building high-end motion systems, these parameters aren’t optional—they’re essential.