In modern automation systems, precision and durability are non-negotiable. Enter the roller type linear guide—a breakthrough motion technology that replaces conventional ball-bearing or sliding systems with cylindrical rollers for superior rigidity, contaminant resistance, and maintenance-free operation.

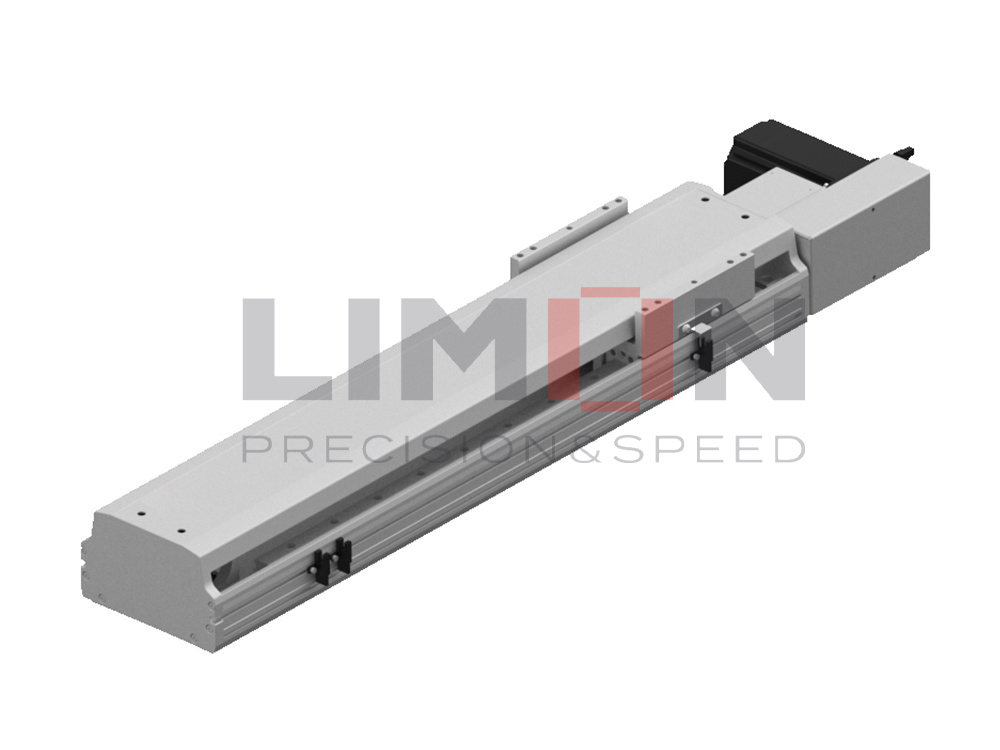

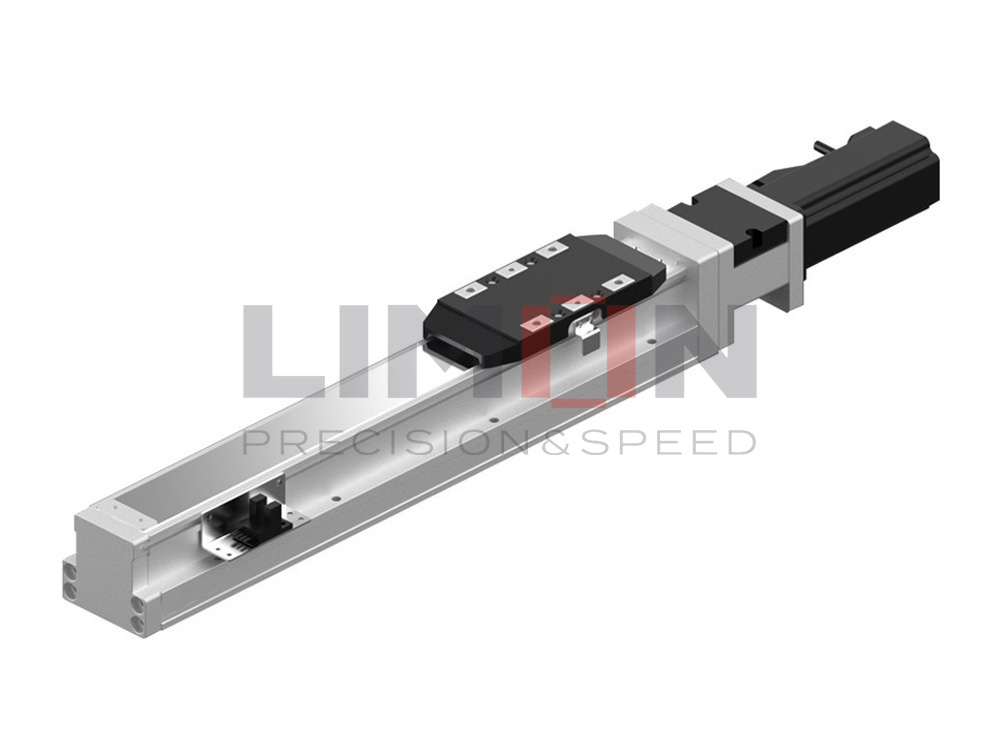

Developed by top linear guide manufacturers like LIMON, these guides utilize a V-shaped roller-and-rail design to achieve ultra-smooth, high-load motion, even in the harshest environments. Whether you’re automating food packaging, semiconductor handling, or heavy equipment, roller type linear guides provide the kind of stability your system can build on.

Why Use a Roller Type Linear Guide?

Unlike traditional linear motion systems, the roller type linear guide stands out in several ways:

No Lubrication Required – Maintenance-free design reduces downtime.

Dust & Debris Resistant – V-groove rollers self-clean with each pass.

High Load Capacity – Ideal for heavy-duty industrial applications.

Longevity – Precision-ground rails resist wear, even under high-frequency motion.

Comparison: Traditional Guides vs. LIMON Roller Type Linear Guide

| Feature | Regular Guides | LIMON Roller Type Linear Guide |

|---|---|---|

| Contaminant Resistance | Prone to clogging | Self-cleaning V-groove rollers |

| Maintenance | Frequent lubrication needed | Zero-lubrication operation |

| Modularity | Fixed configurations | Modular components for custom layouts |

| Precision | Moderate | Micron-level repeatability |

Why Choose LIMON as Your Linear Guide Manufacturer?

1. Built for Harsh Environments

LIMON’s patented V-roller design actively expels contaminants, from metal shavings to flour dust. Stainless steel variants resist corrosion—ideal for food processing, marine, and pharmaceutical industries.

2. Precision That Powers Innovation

Engineered for robotics and semiconductor applications, these guides deliver micron-level positioning accuracy with minimal vibration.

3. Modular for Any Workflow

Thanks to modular design, LIMON roller guides integrate seamlessly across multi-axis setups. Vertical, horizontal, or overhead—configure your assembly line your way.

4. Maintenance-Free Operation

With no oil or grease required, your team spends less time servicing machinery and more time producing. Perfect for cleanroom or food-grade environments.

5. Sustainable Engineering

Zero-lubricant waste. Longer system lifespan. LIMON’s design supports green manufacturing and circular economy goals.

6. Global Support with Local Insight

From CAD libraries to custom mounting kits, LIMON provides end-to-end engineering support for industries including automotive, aerospace, packaging, and medical devices.

Conclusion: Roller Type Linear Guides by LIMON Deliver Precision, Durability, and Peace of Mind

If your automation system demands zero downtime, high-load handling, and micron-level accuracy, there’s only one answer: roller type linear guides from LIMON. As one of the most trusted linear guide manufacturers worldwide, LIMON combines innovative engineering with real-world reliability.