A: We pay great attention with the quality of our products and we have many quality certificates: ISO9001, ISO14001, CE European Union certification certificate, ROHS certificate etc.

Applicable industries of R series:

CNC machining centers,Heavy duty cutting machine,CNC grinding machine

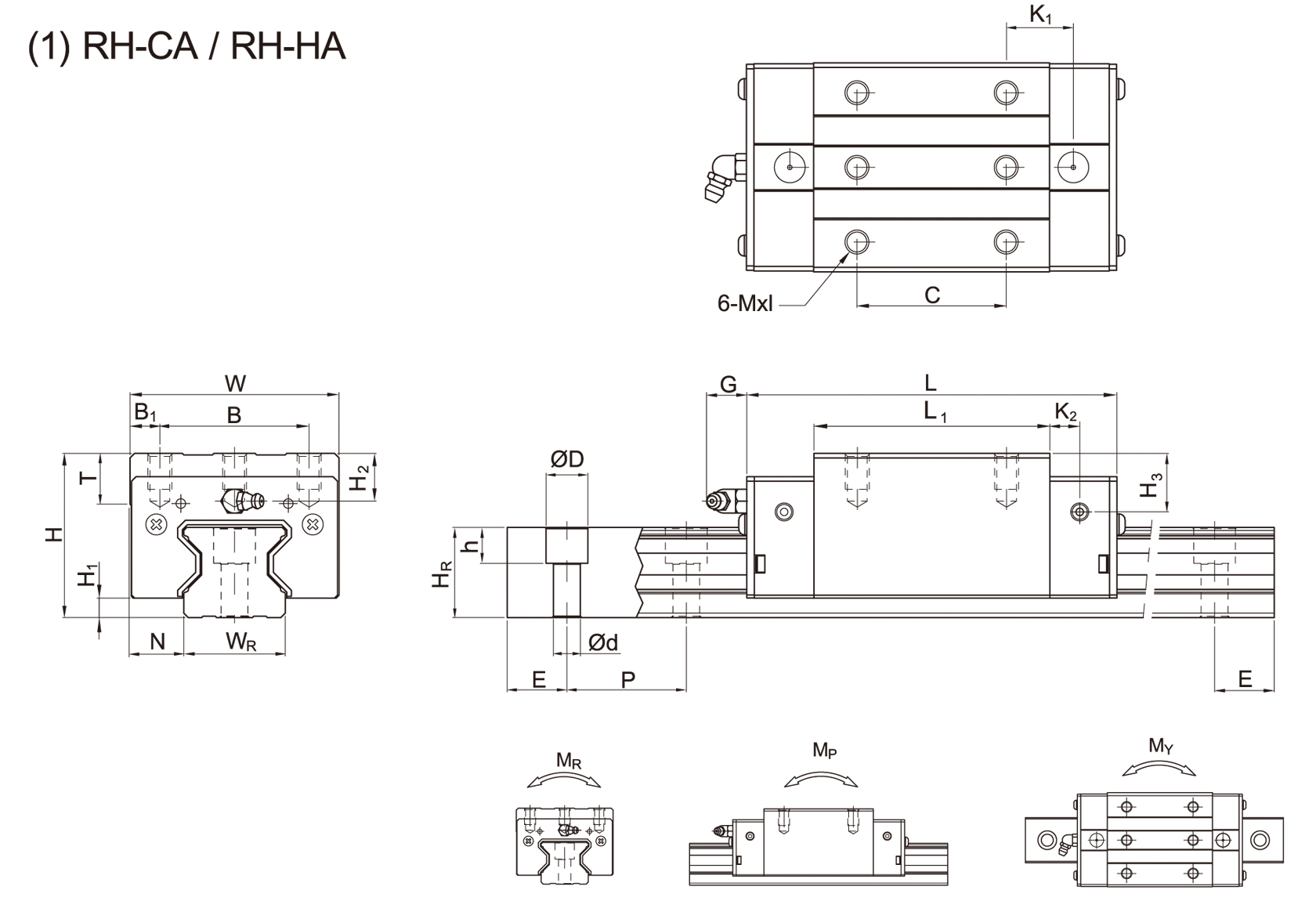

(1) Optimal design

FEM analysis was performed to determine the optimal structure of the block and the rail. The unique design of the circulation path allows the R series linear guideway to offer smoother linear motion.

(2)Super high rigidity

The R series is a type of linear guideway that uses rollers as the rolling elements. Rollers have a greater contact area than balls so that the roller guideway features higher load capacity and greater rigidity. The figure shows the rigidity of a roller and a ball with equal volume.

(3)Super high load capacity

With the four rows of rollers arranged at a contact angle of 45-degrees, the R series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. The R series has a higher load capacity in a smaller size than conventional, ball-type linear guideways.

(4)Operating life increased

Compare with the ball element, the contact pressure of rolling element is distributed on the line region. Therefore, stress concentration was reduced significantly and the R series offers longer running life. The nominal life of R series can be calculated by using Eq.

Model NO. | Dimensions of | Dimensions of | Dimensions of | Mounting Bolt for Rail | Basic Dynamic Load Rating | Basic Static Load Rating | Static Rated Moment | Weight | |||||||||||||||||||||||

MR | MP | MY | Block | Rail | |||||||||||||||||||||||||||

H | H1 | N | W | B | B1 | C | L1 | L | K1 | K2 | G | MxL | T | H2 | H3 | WR | HR | D | h | d | P | E | (mm) | C(kN) | C0(kN) | ||||||

RH15CA | 24 | 4 | 9.5 | 34 | 26 | 4 | 26 | 45 | 68 | 13.4 | 4.7 | 5.3 | M4x8 | 6 | 7.6 | 10.1 | 15 | 16.5 | 7.5 | 5.7 | 4.5 | 30 | 20 | M4x16 | 11.3 | 24 | 0.311 | 0.17 | 0.17 | 0.2 | 1.8 |

RH20CA | 34 | 5 | 12 | 44 | 32 | 6 | 36 | 57.5 | 86 | 15.8 | 6 | 5.3 | M5x8 | 8 | 8.3 | 8.3 | 20 | 21 | 9.5 | 8.5 | 6 | 30 | 20 | M5x20 | 21.3 | 46.7 | 0.647 | 0.46 | 0.46 | 0.40 | 2.76 |

RH20HA | 50 | 77.5 | 106 | 18.8 | 26.9 | 63 | 0.872 | 0.837 | 0.837 | 0.53 | |||||||||||||||||||||

RH25CA | 40 | 5.5 | 12.5 | 48 | 35 | 6.5 | 35 | 64.5 | 97.9 | 20.75 | 7.25 | 12 | M6x8 | 9.5 | 10.2 | 10 | 23 | 23.6 | 11 | 9 | 7 | 30 | 20 | M6x20 | 27.7 | 57.1 | 0.758 | 0.605 | 0.605 | 0.61 | 3.08 |

RH25HA | 50 | 81 | 114.4 | 21.5 | 33.9 | 73.4 | 0.975 | 0.991 | 0.991 | 0.75 | |||||||||||||||||||||

RH30CA | 45 | 6 | 16 | 60 | 40 | 10 | 40 | 71 | 109.8 | 23.5 | 8 | 12 | M8x10 | 9.5 | 9.5 | 10.3 | 28 | 28 | 14 | 12 | 9 | 40 | 20 | M8x25 | 39.1 | 82.1 | 1.445 | 1.06 | 1.06 | 0.90 | 4.41 |

RH30HA | 60 | 93 | 131.8 | 24.5 | 48.1 | 105 | 1.846 | 1.71 | 1.71 | 1.16 | |||||||||||||||||||||

RH35CA | 55 | 6.5 | 18 | 70 | 50 | 10 | 50 | 79 | 124 | 22.5 | 10 | 12 | M8x12 | 12 | 16 | 19.6 | 34 | 30.2 | 14 | 12 | 9 | 40 | 20 | M8x25 | 57.9 | 105.2 | 2.17 | 1.44 | 1.44 | 1.57 | 6.06 |

RH35HA | 72 | 106.5 | 151.5 | 25.25 | 73.1 | 142 | 2.93 | 2.60 | 2.60 | 2.06 | |||||||||||||||||||||

RH45CA | 70 | 8 | 20.5 | 86 | 60 | 13 | 60 | 106 | 153.2 | 31 | 10 | 12.9 | M10x17 | 16 | 20 | 24 | 45 | 38 | 20 | 17 | 14 | 52.5 | 22.5 | M12x35 | 92.6 | 178.8 | 4.52 | 3.05 | 3.05 | 3.18 | 9.97 |

RH45HA | 80 | 139.8 | 187 | 37.9 | 116 | 230.9 | 6.33 | 5.47 | 5.47 | 4.13 | |||||||||||||||||||||

RH55CA | 80 | 10 | 23.5 | 100 | 75 | 12.5 | 75 | 125.5 | 183.7 | 37.75 | 12.5 | 12.9 | M12x18 | 17.5 | 22 | 27.5 | 53 | 44 | 23 | 20 | 16 | 60 | 30 | M14x45 | 130.5 | 252 | 8.01 | 5.4 | 5.4 | 4.89 | 13.98 |

RH55HA | 95 | 173.8 | 232 | 51.9 | 167.8 | 348 | 11.15 | 10.25 | 10.25 | 6.68 | |||||||||||||||||||||

RH65CA | 90 | 12 | 31.5 | 126 | 76 | 25 | 70 | 160 | 232 | 60.8 | 15.8 | 12.9 | M16x20 | 25 | 15 | 15 | 63 | 53 | 26 | 22 | 18 | 75 | 35 | M16x50 | 213 | 411.6 | 16.20 | 11.59 | 11.59 | 8.89 | 20.22 |

RH65HA | 120 | 223 | 295 | 67.3 | 275.3 | 572.7 | 22.55 | 22.17 | 22.17 | 12.13 | |||||||||||||||||||||

Note: 1. 1kgf = 9.81N | |||||||||||||||||||||||||||||||

A: We pay great attention with the quality of our products and we have many quality certificates: ISO9001, ISO14001, CE European Union certification certificate, ROHS certificate etc.

A: Yes, sample is available. If you are interested, you can contact us by e-mail ([email protected]) to get more photos and information.

A: Normal order delivery of linear motion products is generally controlled within 1-2 months.

Normal order delivery for linear unit and higher precision products is generally controlled within 7-15 working days.

A: Our cooperating transportation companies include DHL, TNT, UPS, etc. Sea transportation, air transportation and express delivery are all available. If you have a specific carrier, please let us know when you place the order.

A: You can contact us by e-mail ([email protected] ) and we will recommend the most suitable project according to your requirements.

A: T/T in advance.

A: LIMON agent in Asia: Singapore, Japan, India

LIMON agent in Europe: Hungary, Turkey, Israel

LIMON agent in South America: Brazil

A: LIMON do quite well in Europe, Asia and South America, also China is a potential market for us. Now LIMON’s distributors have covered more than 32 country and regions.

A: We are really looking forward to having you as a solid partner of LIMON. Please contact us by e-mail ([email protected] ) , we can start talk and get to know more about each other.

Welcome to discuss your purchasing requirements with our customer service.