A: We pay great attention with the quality of our products and we have many quality certificates: ISO9001, ISO14001, CE European Union certification certificate, ROHS certificate etc.

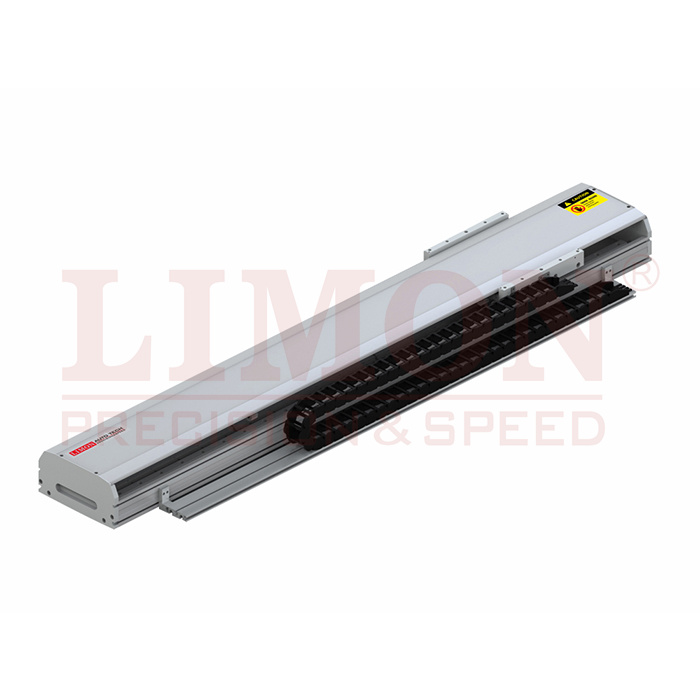

Linear Motor Driven

WLO Series

WLO14

Classification: WLO Series

Drive type: Motor drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 148*89mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

| Technical Parameters | Type | WLO14- C1 | WLO14- C2 |

| Driving Method | Linear Motor Driven Type With Iron Core | ||

| Repetitive Accuracy (μ) | 5 #1 | ||

| Continuous Thrust(N) | 40 | 80 | |

| Max Thrust(N) | 120 | 240 | |

| Max Accelerated Speed (M/S²) | 4G | ||

| Max Speed (MM/S) | 4000 | ||

| Basic Specification | Standard Stroke (mm) | 143-2303 mm/108 pitch | |

| Max Outline of Main Engine’s Cross Section | 148*89 | ||

| High Stiffness Linear Guide (mm) | 15 Guide 2PCS | ||

| Internal Capacity of Caterpillar Band | 17*25 | ||

| Home Sensor | EE-SX672(NPN) | ||

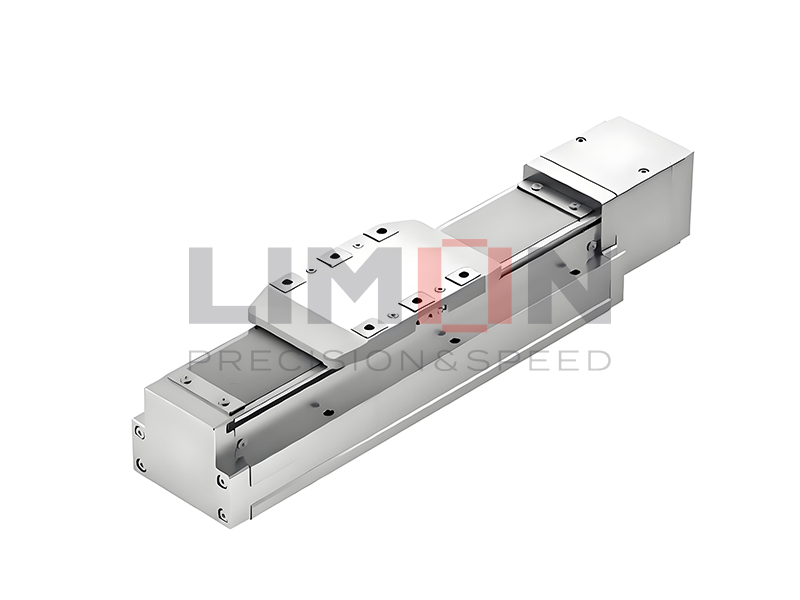

WLO17

Classification: WLO Series

Drive type: Motor drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section:183*102mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

| Technical Parameters | Type | WLO17-C1 | WLO17-C2 |

| Driving Method | Linear Motor Driven Type With Iron Core | ||

| Repetitive Accuracy (μ) | 5 #1 | ||

| Continuous Thrust(N) | 80 | 160 | |

| Max Thrust(N) | 240 | 480 | |

| Max Accelerated Speed (M/S²) | 4G | ||

| Max Speed (MM/S) | 4000 | ||

| Basic Specification | Standard Stroke (mm) | 143-2303 mm/108 pitch | |

| Max Outline of Main Engine’s Cross Section | 183*102 | ||

| High Stiffness Linear Guide (mm) | 20 Guide 2PCS | ||

| Internal Capacity of Caterpillar Band | 17*25 | ||

| Home Sensor | EE-SX672(NPN) | ||

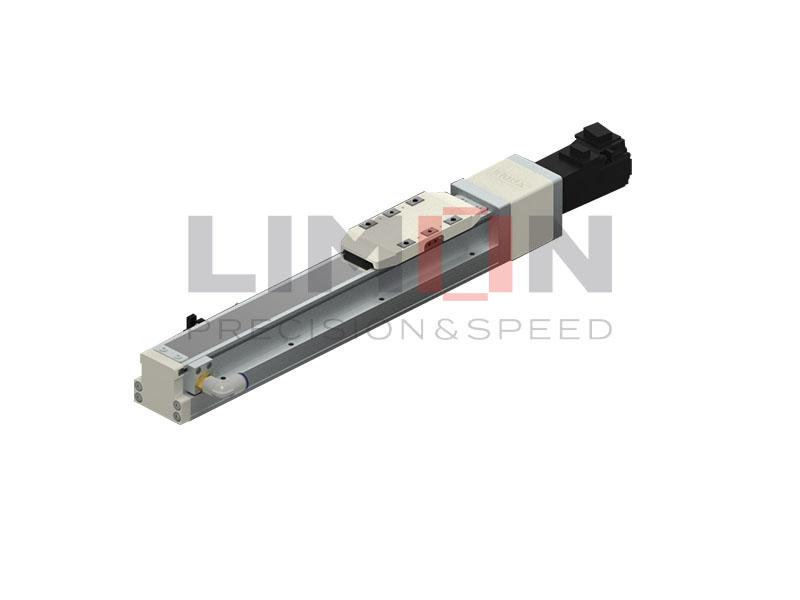

WLO22

Classification: WLO Series

Driver type: Motor drive

Sealed type: general environment, semi sealed

Repeat positioning accuracy: ±0.05mm

Maximum dimension of main section: 233*120mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

| Technical Parameters | Type | WLO22-C1 | WLO22-C2 |

| Driving Method | Linear Motor Driven Type With Iron Core | ||

| Repetitive Accuracy (μ) | 5 #1 | ||

| Continuous Thrust(N) | 280 | 560 | |

| Max Thrust(N) | 840 | 1680 | |

| Max Accelerated Speed (M/S²) | 4G | ||

| Max Speed (MM/S) | 4000 | ||

| Basic Specification | Standard Stroke (mm) | 143-2303 mm /135 pitch | |

| Max Outline of Main Engine’s Cross Section | 233*120 | ||

| High Stiffness Linear Guide (mm) | 25 Guide 2PCS | ||

| Internal Capacity of Caterpillar Band | 17*25 | ||

| Home Sensor | EE-SX672(NPN) | ||

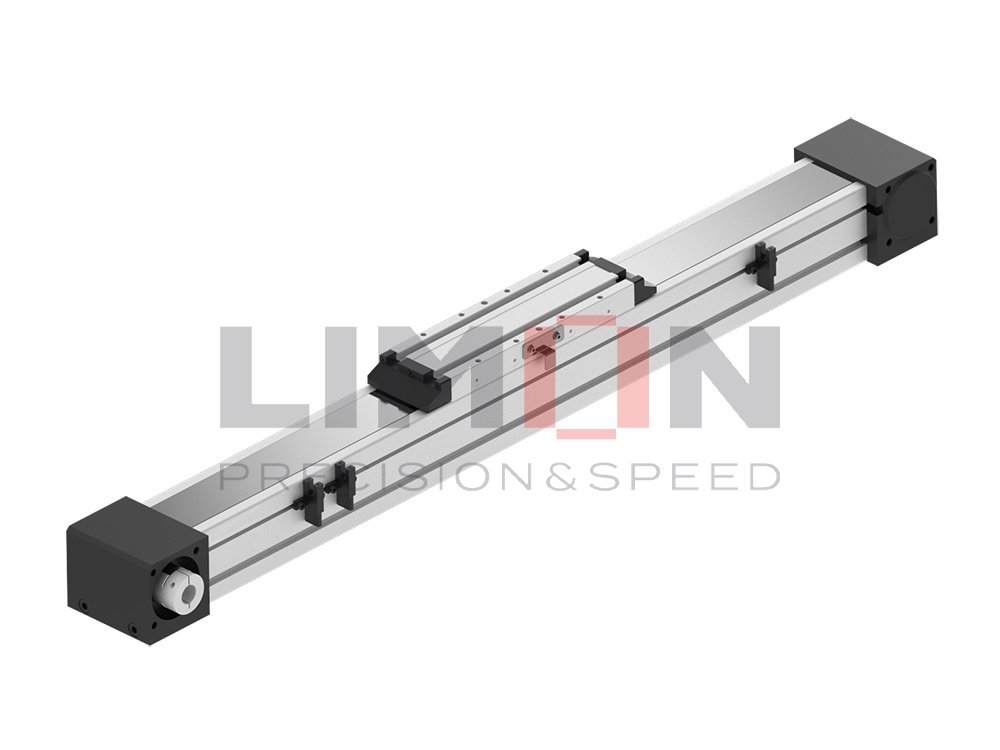

Description

Linear Motor

Application industry:

3D Scanner, Image Scanning, Laser Testing, High-end automation equipment, LCD panel high-speed laser drilling machine, all-linear motor six-axis CNC drilling machine, high-speed and high-precision SMT mounter, high-speed transplanting equipment

Before the advent of practical and affordable linear motors, all linear motion had to be converted from rotating machinery by using ball or roller screw or belt or pulley. For many applications, such as heavy load and the drive shaft is vertical. These methods are still the best. However, linear motor has many unique advantages over mechanical system, such as very high speed and very low speed, high acceleration, almost zero maintenance (no contact parts), high precision and no idle return. To complete the linear motion, only the motor is needed, and there is no gear, coupling or pulley. It is very meaningful for many applications. Those unnecessary parts that reduce performance and shorten mechanical life are removed.

Basic Information:

Maximum acceleration: 4G

Ultra-high absolute positioning accuracy <1 min

Full closed loop feedback system

Anti-deformation and vibration design

Core-free vibration (Yaskawa: 0.4; Jacobs: 0.76; hiwin: 0.8)

Setting time is short: the test method is running 0-30.30-0 back movement, which takes 0.052s

Features:

1. Few parts, all can be modular packed and then shipped.

2. The assembly is simple, do not need skilled workers, just need to tighten the screws.

3. Accessories have a high versatility, the same width of the product, except the main carriage module, other materials are all universal.

Our Service:

1. We can provide the whole parts, including mechanical parts, forcer, stator, raster, magnetic grating, driver.

2. Provide calculation tables for pre-sales selection

3. Provide Panasonic installation and commissioning technical guidance.

4. Provide technical guidance for unit assembly and raster installation.

Suitable for handling occasions:

where needs fast speed, long stroke, maximum load within 100KGS, and replace the occasions where use the timing belt & rack and pinion.

Suitable for high precision required occasion:

can be matched with raster ruler, and replace the occasions where use C3 grade grinding ball screw.

PS: No matter raster or magnetic grating, the repetition accuracy can be achieved within ±0.002. They differ mainly in absolute positioning accuracy. If you run a repeat position, recommend to use magnetic grating.

Suitable for high acceleration occasions of emergency stop and walk:

linear motor can generally reach more than 1G, while ball screw can only reach 0.5G.

Frequently Asked Questions

A: Yes, sample is available. If you are interested, you can contact us by e-mail ([email protected]) to get more photos and information.

A: Normal order delivery of linear motion products is generally controlled within 1-2 months.

Normal order delivery for linear unit and higher precision products is generally controlled within 7-15 working days.

A: Our cooperating transportation companies include DHL, TNT, UPS, etc. Sea transportation, air transportation and express delivery are all available. If you have a specific carrier, please let us know when you place the order.

A: You can contact us by e-mail ([email protected] ) and we will recommend the most suitable project according to your requirements.

A: T/T in advance.

A: LIMON agent in Asia: Singapore, Japan, India

LIMON agent in Europe: Hungary, Turkey, Israel

LIMON agent in South America: Brazil

A: LIMON do quite well in Europe, Asia and South America, also China is a potential market for us. Now LIMON’s distributors have covered more than 32 country and regions.

A: We are really looking forward to having you as a solid partner of LIMON. Please contact us by e-mail ([email protected] ) , we can start talk and get to know more about each other.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.