1. Technology Advantages & Explosive Market Demand

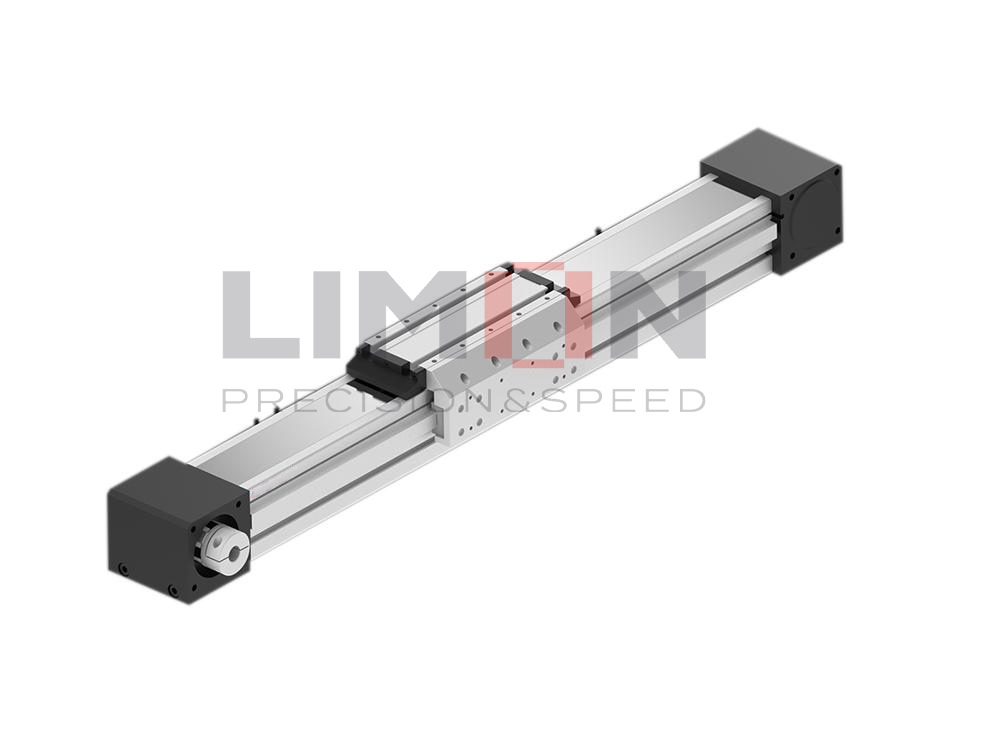

Planetary roller lead screws are revolutionizing humanoid robotics. With three times the load capacity of traditional ball screws, a tripled service life, and high precision (±0.001mm), these lead screws are now indispensable in the joint drives of humanoid robots.

Take Tesla Optimus Gen-2 for instance—its fluid, human-like motion hinges on proprietary planetary roller lead screw actuators. Each robot uses 14 lead screws, contributing to 20% of the robot’s total value.

2. Domestic Production & Cost Disruption

For years, the market was dominated by Swiss giants like GSA and Rollvis, who held over 50% of the global share. But Chinese manufacturers are now breaking this monopoly with a vengeance.

Reverse Engineering + Cost Innovation

Companies like Shuanglin Co., Ltd. and Wuzhou Spring have leveraged reverse design to bring costs down from tens of thousands to mere hundreds of yuan per screw. Game-changing, right?

Shuanglin also acquired Wuxi Kezhixin, integrating high-precision grinding machine technology, slashing equipment investment from ¥10M to ¥3M, and boosting mass production efficiency by 75%.

Meanwhile, Changban Technology announced plans to reach 10,000 units/year in reverse lead screw production by 2025—becoming the first domestic player to go public with such a target.

3. Industrial Chain Synergy & Policy Tailwinds

Policy is giving the sector a major tailwind.

Under China’s 14th Five-Year Plan for Robotics, there’s a clear mandate to localize critical components like planetary roller screws. Cross-industry tech powerhouses like Huawei and BYD have entered the field, injecting both capital and innovation.

The release of the T/CIET 965-2025 industry standard has further aligned domestic planetary roller lead screw production with international benchmarks, solidifying China’s foothold in the global supply chain.

Final Thoughts

With technology advantages, a skyrocketing market, and policy support, domestically produced planetary roller lead screws are positioned to drive the next generation of humanoid robotics—efficiently, affordably, and at scale.