When precision engineering meets compact performance, you get the miniature type linear guide—a marvel of motion control technology. Small in size but mighty in function, these guides are redefining what’s possible in modern automation, robotics, and medical device design.

What Is a Miniature Type Linear Guide?

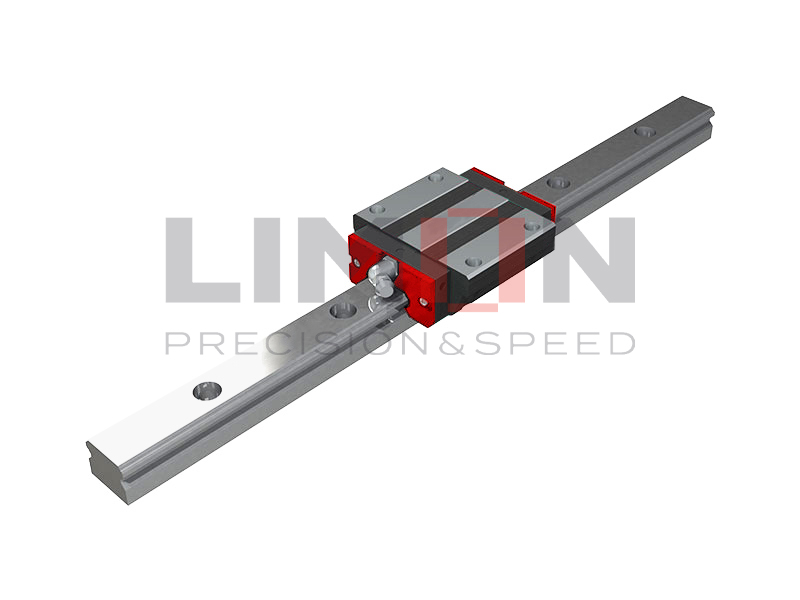

A miniature type linear guide is a scaled-down, high-precision linear motion system designed for smooth, accurate, and low-friction movement. Built for space-constrained environments, it typically features a rail and a slider integrated with precision ball bearings.

This compact configuration is crucial for:

Robotics

Medical devices

Automation systems

Anywhere that demands tight tolerances and minimal footprint, miniature linear guides offer a sleek, effective solution.

Why Use a Miniature Type Linear Guide?

Let’s be honest: when space is at a premium and motion accuracy is non-negotiable, there’s no substitute for a miniature type linear guide.

Top benefits include:

Compact design for space-limited systems

Smooth, low-friction motion for precision control

Reliable operation in demanding applications

Lightweight build without sacrificing durability

They’re the go-to solution for OEMs and engineers building the next generation of intelligent machines.

Miniature vs. Regular Linear Guides

| Feature | Regular Linear Guide | Miniature Type Linear Guide |

|---|---|---|

| Size | Larger, suited for industrial machinery | Compact, fits tight spaces with ease |

| Load Capacity | High, for heavy-duty tasks | Moderate, ideal for lighter precision systems |

| Precision | Variable | Exceptional accuracy |

| Applications | CNC, milling, industrial automation | Medical, robotics, compact automation |

| Cost | Higher due to material volume | Cost-efficient for small-scale systems |

Why LIMON Miniature Linear Guides Are Industry Game-Changers

1. What Makes LIMON Guides Stand Out?

LIMON’s miniature type linear guides are engineered for precision—and built to last. With advanced materials, low-friction coatings, and compact durability, these guides are the choice of innovators in motion control.

2. How LIMON Enhances Automation Efficiency

In automation, every millisecond counts. LIMON’s miniature linear guides offer low-resistance motion, reduced energy use, and pinpoint repeatability—perfect for:

Robotic arms

CNC precision tools

Smart assembly lines

The result? Increased uptime and faster cycles, all without sacrificing accuracy.

3. Key Applications Across Industries

LIMON’s guides are quietly doing big things in:

Medical devices – Think MRI systems, surgical robots, diagnostic platforms

Robotics – Compact actuators and high-speed end effectors

Factory automation – Especially where space and reliability are crucial

Wherever delicate motion meets tight constraints, miniature type linear guides from LIMON shine.

4. LIMON’s Quality Promise

Precision starts at the source. LIMON applies:

Rigorous testing protocols

International manufacturing standards

Top-grade materials and coatings

This ensures every miniature linear guide performs reliably—even under harsh or high-frequency conditions.

5. Real Cost Benefits That Last

While not the cheapest upfront, LIMON’s miniature guides deliver ROI where it counts:

Long service life

Lower maintenance costs

Improved energy efficiency

Reduced system downtime

6. Customer Support That Moves With You

LIMON isn’t just a manufacturer—they’re a partner in motion control. Their support team provides:

Product selection guidance

Installation assistance

Troubleshooting and technical documentation

From quote to commissioning, LIMON has your back.

Final Word

If you’re designing systems where precision, reliability, and compact design matter, there’s no better fit than a miniature type linear guide—and no better brand than LIMON. Engineered to outperform, built to outlast.