Dry Lubrication vs. Oil Lubrication: Application Scenarios

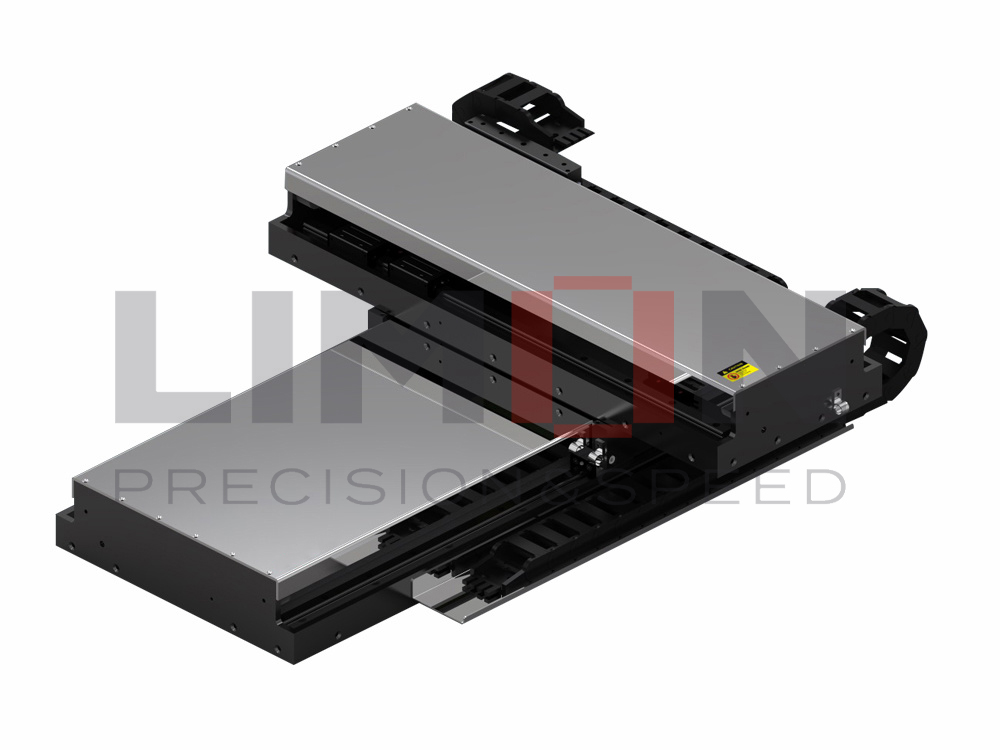

In the realm of linear motion products, lubrication plays a pivotal role in ensuring performance, longevity, and reliability. Two principal lubrication methods dominate the landscape—dry lubrication and oil-based lubrication. Each of these methods has unique strengths and applications, and choosing the correct method is critical for maximizing performance in different industrial environments. This section explores these lubrication strategies in depth, especially in relation to LIMON’s advanced linear guideway systems and broader trends within the automation industry.

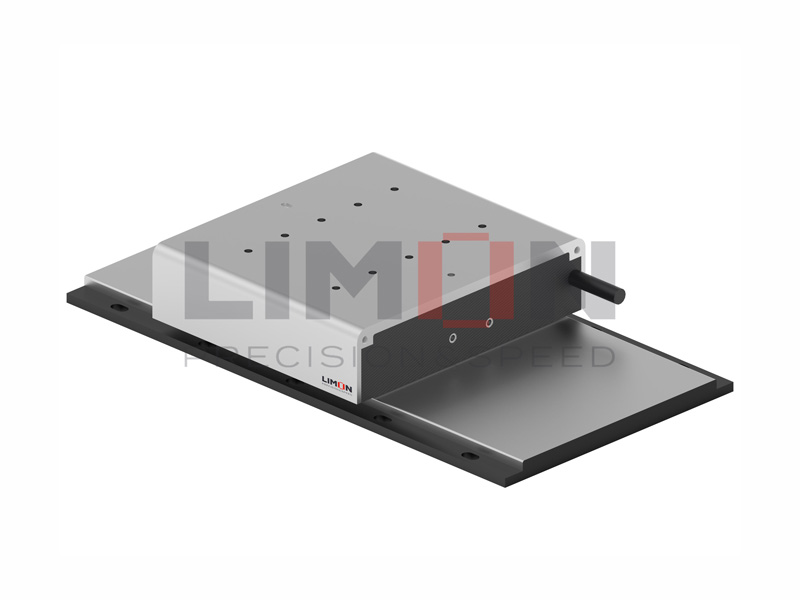

Dry lubrication refers to the use of solid lubricants like graphite, molybdenum disulfide, or embedded lubrication blocks, often made from engineered plastics. LIMON linear guideways, such as their self-lubricating series, incorporate these technologies to minimize wear and eliminate the need for frequent manual maintenance. Dry lubrication excels in cleanroom applications, such as semiconductor manufacturing, where contamination control is paramount. These self-lubricating materials are embedded directly into the guideway’s structure, reducing particle emission and making them ideal for vacuum environments as well.

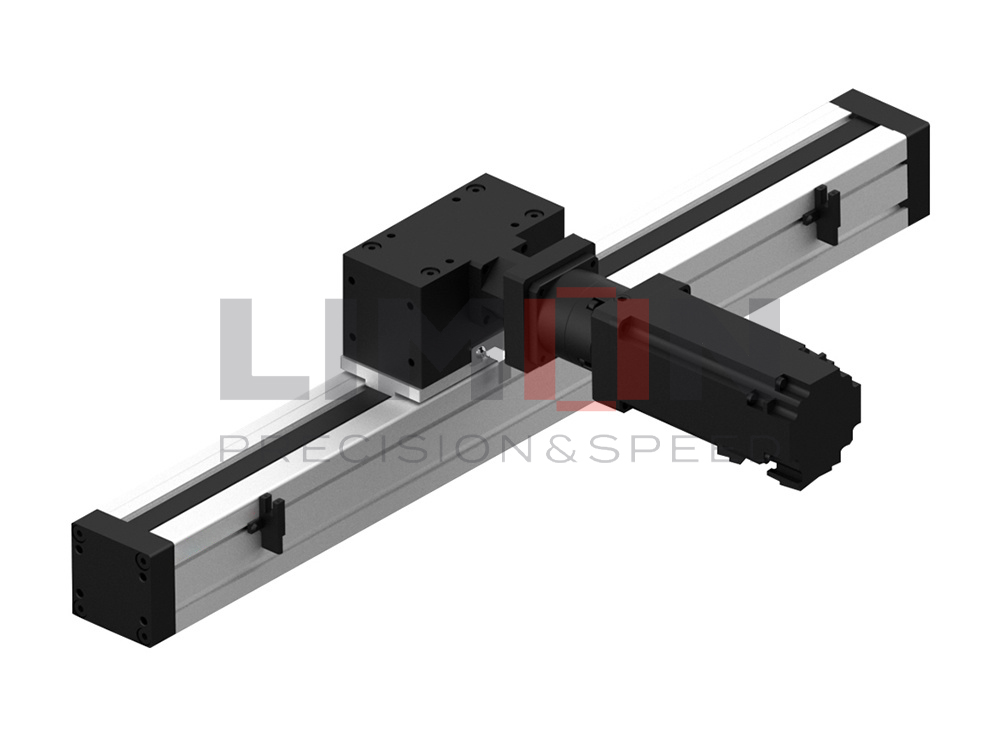

On the other hand, oil lubrication involves applying mineral or synthetic oils to reduce friction and wear. LIMON’s oil lubrication models are designed for high-load and high-speed scenarios commonly seen in CNC machining, transportation systems, and robotic automation lines. These systems often include automated lubrication units that precisely control the volume and timing of oil application, optimizing efficiency and reducing downtime.

Linear guide manufacturers like LIMON offer hybrid solutions to bridge these two approaches. Depending on application requirements—such as ambient temperature, presence of corrosive agents, or mechanical stress—users can select a customized lubrication system. Ultimately, understanding the working environment and performance goals is essential to determine the most suitable method.

Maintenance Cycle Adjustments in Extreme Environments

In dusty or high-temperature environments, linear guideways need more frequent lubrication and inspections. Heat-resistant lubricants and sealed units extend intervals and improve system life.

Extreme environments such as desert regions, steel plants, or foundries expose linear guideways to abrasive particles and heat stress. In these conditions, standard lubrication schedules may no longer suffice. Instead, maintenance intervals should be halved or adjusted based on real-time monitoring of guideway performance indicators, such as noise, vibration, and temperature spikes.

LIMON’s sealed linear guideway systems, equipped with thermally stable lubricants and advanced dust wipers, are purpose-built to address such challenges. Integrating sensor-based predictive maintenance platforms allows users to automate alerts for lubrication reapplication and inspection, minimizing unplanned downtime. Specialized greases that resist oxidation at high temperatures further help extend service intervals, even in harsh conditions.

Overlooked Maintenance Details in User Self-Service

Skipping pre-cleaning or using incompatible lubricants often causes premature failure. Careful planning and reference to manuals prevent this.

Users often underestimate the importance of environment-specific lubricant selection and surface preparation. For example, mixing synthetic and mineral oils can cause degradation, while neglecting to remove old grease before reapplication may result in abrasive sludge formation. Simple habits like wiping the rail with lint-free cloths and storing lubricants in temperature-controlled areas drastically improve system performance.

Don’t stop here—our next section dives deeper into advanced strategies for extreme environments.

Customized Maintenance Solutions for Special Operating Conditions

1.Selection of Corrosion-Resistant Lubricants in the Food Processing Industry

In food processing, hygiene and corrosion resistance are paramount. Stainless steel linear motion components paired with NSF H1-certified food-grade lubricants ensure compliance with safety regulations while resisting aggressive washdowns and acidic exposure. LIMON’s stainless track systems and sealed blocks are specially engineered for such environments, supporting both sanitation and mechanical durability.

Lubricants used in food applications must resist emulsification and maintain viscosity across variable temperatures. LIMON’s proprietary lubrication solutions include high-performance greases and oils that adhere to component surfaces, maintaining their lubricating function even during repeated cleaning procedures.

To guarantee system safety and durability, food-grade lubricants must also resist oxidation and microbial growth. Selecting products with anti-microbial additives further extends the lifespan of the linear guideway and enhances food safety.

2.Cleanroom Maintenance Procedures in Semiconductor Workshops

Cleanrooms, particularly in semiconductor fabrication, impose stringent cleanliness and contamination control requirements. Particles emitted from lubricants or worn surfaces can compromise entire manufacturing batches. As a result, linear guide manufacturers like LIMON prioritize low-particle-emission materials and self-lubricating designs.

LIMON’s cleanroom-optimized models use embedded lubrication systems within polymeric cages and sealed bearing blocks, effectively preventing lubricant leakage. Regular maintenance involves dry wiping, replacement of cleanroom-compatible end seals, and monitoring with particle counters. Automated lubrication systems that use vacuum-rated lubricants are preferred.

Maintenance staff in such settings must wear ESD-safe clothing and follow protocols to prevent particle dispersion. All consumables used during maintenance must be ISO Class 5 or better, further underscoring the importance of meticulous protocol adherence.

3.Waterproof and Rustproof Treatments for Outdoor Engineering Machinery

Outdoor applications such as construction machinery face unpredictable weather conditions, water ingress, and exposure to corrosive agents. LIMON’s outdoor-rated linear motion products include stainless steel rails with nickel or chrome plating, integrated wipers, and IP65-rated seals.

Rustproofing begins with material selection—high-alloy steels or specially treated aluminum bases. Lubricants must be hydrophobic and capable of forming a protective film even in wet environments. LIMON recommends lithium-thickened greases and synthetic oils with anti-corrosion additives.

Preventive maintenance protocols involve regular inspections post-rainfall or high-humidity periods, reapplication of corrosion inhibitors, and visual checks of seal integrity. Component lifetime is significantly extended through periodic re-lubrication and environmental monitoring.

4.Lubrication Compatibility Issues in High Vacuum Environments

High vacuum environments, common in space simulation chambers or advanced electronics labs, demand lubricants that do not outgas or degrade under vacuum pressure. Traditional oils and greases release volatile organic compounds that can compromise vacuum integrity.

LIMON addresses this through vacuum-compatible lubricants like PFPE-based greases and engineered dry lubrication coatings. These materials are chemically inert and possess extremely low vapor pressures, ensuring performance without contamination.

Maintenance in vacuum setups often involves in-situ baking or purging, so lubricants must remain stable at elevated temperatures. LIMON’s high-vacuum guideways include specialized surface treatments to improve bonding with advanced lubricants, preventing micro-migration during thermal cycling.

Conclusion

Strategic lubrication and maintenance optimize performance and longevity across industries. Choose tailored solutions based on application needs.