Technical Specifications and Options

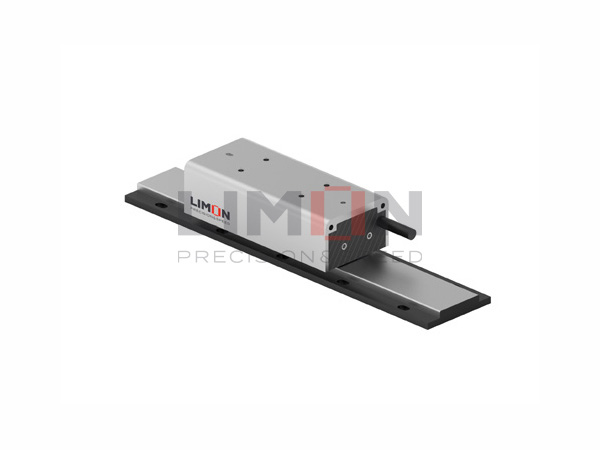

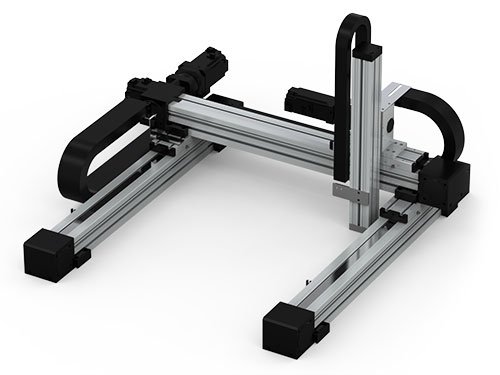

LIMON’s linear modules offer a variety of technical specifications and options to suit diverse applications. They provide systems with load capacities ranging from light-duty to heavy-duty, depending on the required performance. The modules can be customized for different speeds, travel lengths, and load handling capabilities, offering both compact designs and precision motion control. Options include integration with stepper or servo motors for enhanced control, as well as various mounting configurations for ease of installation.

- belt drive,ball screw drive, rack & pinion drive, linear motor drive

- for high speeds and high precision requirements

- high travel speeds up to 4m/s

- overall stroke up to 12 m

- loads up to 300 kg

- Variousproduct range for different applications

- Support customized solution and different type ofmulti-axis systems

How Does a Linear Axis Work?

A linear axis operates by converting rotational motion from a motor into straight-line motion. The motor typically drives a ball screw, belt, or rack, which moves a carriage along a set of guide rails. As the motor turns, it either rotates a ball screw or pulls a belt, generating linear movement. This allows machines to position tools, parts, or other components with precision along the defined path. The system’s design minimizes friction and backlash, ensuring smooth and repeatable motion for various tasks.

Which Industry Can Apply a Linear Axis?

Linear axes are versatile components used in many industries requiring precision and reliable motion systems. These include:

- Manufacturing & CNC: Linear axes are crucial in CNC machines and manufacturing processes for high-precision cutting, milling, and drilling.

- Robotics: In robotic arms, linear axes provide the necessary movement for assembly, handling, and packaging applications.

- Automation & Packaging: Automated systems and conveyors rely on linear axes to move products, materials, and tools efficiently in packaging lines.

- Medical: Linear systems are used in medical devices for precise positioning and movement, including imaging equipment and robotic surgery tools.

- Aerospace: Linear motion systems play a vital role in testing, assembly, and research equipment in the aerospace industry.

- Food & Beverage: Linear axes assist in sorting, packaging, and moving products along production lines in the food and beverage sector.

List of 10 Linear Axes Manufacturers

The linear axis market features several leading manufacturers known for their high-quality products. Here is a list of 10 key players:

Certainly! Here is the revised list with one sentence per brand, limited to 20 words:

Got it! Here is the updated list without bolding the industry information:

- THK (Japan): Premium, high-precision products focused on robotics, CNC machining, automation, and semiconductor manufacturing industries.

- HIWIN (Taiwan): High-performance, cost-effective systems targeting industrial automation, robotics, and material handling sectors.

- Bosch Rexroth (Germany): Premium solutions for automotive, industrial automation, packaging, and machine tools industries.

- Festo (Germany): High-quality automation systems used in robotics, food and beverage, and pharmaceutical industries.

- LIMON (China): Reliable, competitive linear motion solutions for automation, machinery, robotics, and conveying systems industries.

- Kollmorgen (USA): High-precision systems serving robotics, aerospace, automotive, and industrial automation sectors.

- Parker Hannifin (USA): Durable, high-quality systems for hydraulics, automation, robotics, and manufacturing systems sectors.

- Nedella (France): Precision engineering systems focusing on industrial automation, robotics, and CNC machining applications.

- Schneider Electric (France): Known for energy-efficient automation solutions in industrial automation, energy management, and building systems.

- NSK (Japan): Excellent precision and durability, ideal for CNC machines, robotics, material handling, and automotive industries.

These companies are renowned for their innovation and high-precision products, offering a variety of linear motion systems, from basic linear rails to complex multi-axis solutions. Each manufacturer brings a unique expertise in serving different industries’ needs for linear motion and automation systems.

How to Choose Different Types of Linear Axis?

Choosing the right linear axis depends on the specific requirements of your application. Consider the following factors when selecting:

- Precision Requirements: If your application demands high precision, such as in CNC machining or robotics, ball screw-driven or linear motor-driven axes are ideal.

- Load Capacity: For heavy-duty tasks, such as material handling in industrial machines, rack & pinion or ball screw-driven axes can carry higher loads.

- Speed Needs: For high-speed applications like conveyors or packaging systems, belt-driven axes are typically more cost-effective.

- Space Constraints: If space is limited, compact linear modules or integrated multi-axis systems may be necessary to save on floor space while providing full functionality.

- Environmental Conditions: If your linear axis system operates in harsh environments, ensure that the selected system is protected against dust, water, or other contaminants by choosing sealed or dustproof designs.