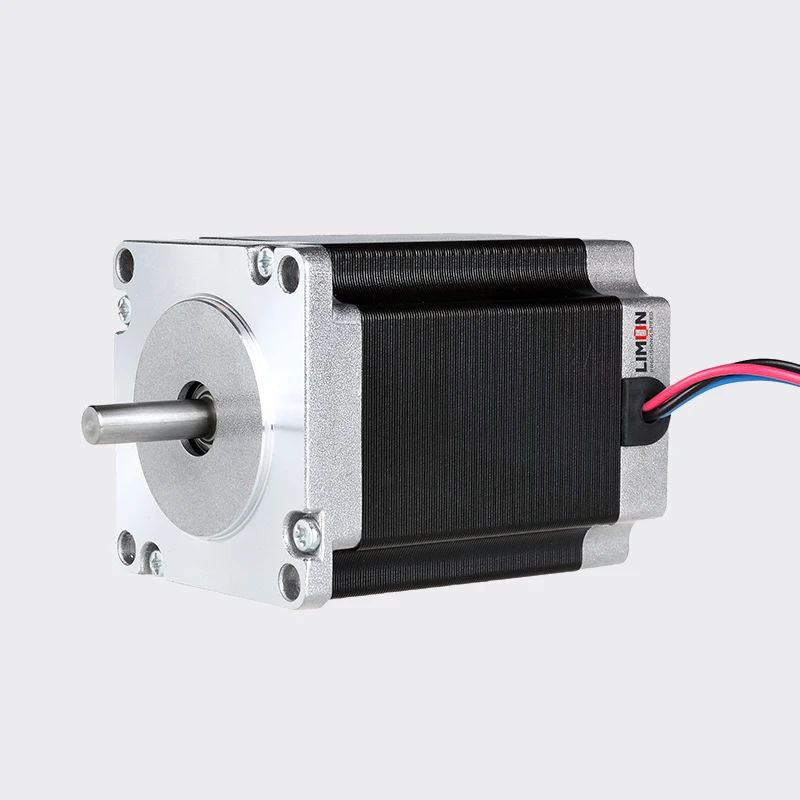

Connecting a stepper motor without a driver results in erratic movement, overheating, and system failure. A proper driver ensures voltage control, power regulation, and motion precision—read on to learn why.

A stepper motor requires a driver to regulate voltage, current, speed, and power output. The stepper motor driver ensures reliable, smooth, and efficient motion in automated systems.

Keep reading to understand how a driver empowers your stepper motor system.

The Motor Needs the Driver to Adjust the Voltage and Current

A stepper motor does not operate effectively when connected directly to a power source. It requires a stepper motor driver to control the voltage and current applied to its windings. Unlike brushed DC motors that accept direct voltage, stepper motors function through sequential energizing of coils in precise patterns.

Without a driver, supplying full voltage directly to the motor coils can result in:

Coil overheating

Inconsistent torque

Excessive power draw

Poor motion control

Stepper motor drivers use pulse-width modulation (PWM) and chopper control techniques to manage how much current flows through each phase. These drivers regulate the supply voltage—often higher than the motor’s rated voltage—to improve performance without exceeding current limits.

In high-precision or industrial systems, using constant-current drivers ensures thermal protection, stability, and efficiency. They protect the motor from damaging spikes while enabling consistent torque delivery. Adjusting voltage and current also enables the use of microstepping, which improves motion resolution.

In essence, the stepper motor driver is not just a control tool—it’s a critical power regulation component tailored to each motor’s electrical characteristics.

The Stepper Motor Needs a Driver to Control the Speed

A stepper motor moves in discrete steps, with the step rate determining how fast the shaft rotates. However, this speed cannot be controlled simply by increasing voltage or connecting to a battery. It requires precise timing of pulse signals—something only a stepper motor driver can provide.

Speed control in stepper motors involves:

Pulse frequency: More pulses per second = higher RPM

Acceleration/deceleration profiles: Gradual ramping prevents missed steps

Microstepping: Smoother motion at varying speeds

A driver converts logic-level signals from a microcontroller or motion controller into controlled pulses that rotate the motor. For example, a 200-step motor driven at 1,000 pulses per second will rotate at 300 RPM. Without a driver to manage this frequency and signal integrity, performance degrades quickly.

Modern stepper motor drivers include features like:

Adjustable pulse frequency

Configurable microstep resolution

Ramp control for smooth start/stop

This enables high-speed movement without compromising positional accuracy. Especially in applications like 3D printing, textile feeding, and pick-and-place robotics, smooth and reliable speed variation is essential. The driver handles all of this logic efficiently, freeing the main controller to focus on system-level decisions.

The Driver of a Stepper Motor Can Provide Higher Output Power

The ability to deliver higher output power is a critical advantage of using a stepper motor driver. Motors themselves don’t “generate” power—they respond to what is supplied. The driver acts as a power amplifier, taking logic signals and delivering regulated electrical energy to the motor’s windings.

Stepper motors often have rated voltages as low as 2–5V per phase, but for high-speed operation, they’re driven by voltages of 24V, 36V, or even 48V. How is that possible? The driver controls the current, not the voltage. By using current-limiting techniques, it applies a high voltage across the coil briefly and then chops the current to safe levels.

Benefits of driver-boosted output power include:

Higher torque at higher speeds

Faster response time

Overcoming load inertia during startup

Maintaining torque under variable load conditions

For instance, a high-performance driver delivering 4A per phase allows a NEMA 23 motor to deliver maximum holding torque and fast acceleration, making it suitable for CNC routers or heavy-duty robotic arms.

Therefore, the motor’s true capability can only be unleashed when paired with a driver capable of high current and voltage delivery—while protecting it from overcurrent, undervoltage, or short-circuit faults.

The Output Power of the Motor Is Related to Its Driver

A stepper motor’s output power—torque multiplied by rotational speed—is directly influenced by the capabilities and configuration of its driver. Even if the motor is physically capable, poor driver selection can limit its actual performance.

Key factors affecting motor output power:

Driver current limit: If the current is too low, torque suffers

Voltage range: Insufficient voltage leads to poor high-speed torque

Stepping mode: Full-step drivers may cause mechanical resonance; microstepping offers smoother motion but may reduce peak torque

Driver efficiency: Poor heat dissipation or chopper design reduces usable power

Advanced drivers dynamically adjust current based on the motor’s motion state—reducing idle current and boosting current during acceleration. This intelligent power management allows motors to perform efficiently across a wide RPM range.

For example:

A poorly tuned driver may allow a stepper to deliver only 50% of its rated torque.

A well-matched, properly cooled driver can maintain 90–100% torque up to mid-speed ranges.

If your motor underperforms in a real-world application, often the culprit isn’t the motor itself but an underpowered or mismatched driver. This makes careful driver selection and setup a top priority in motion system design.

The Driver Can Provide Higher Output Power to Meet the Needs of the Motor

As applications grow more demanding, motors require higher power input to deliver precise, rapid, or heavy-load motion. A stepper motor driver designed with ample current capacity, high-voltage tolerance, and dynamic control algorithms enables motors to meet these higher performance requirements.

In modern systems, motors may need to:

Accelerate quickly with heavy loads

Maintain torque at high speeds

Drive complex, multi-axis motion profiles

Operate in hot or harsh environments

The driver ensures the motor receives enough current during acceleration while also protecting it from overheating or overload. Features such as programmable current curves, idle current reduction, and over-temperature shutoff give the motor greater performance without compromising safety.

A well-engineered stepper motor driver is therefore more than just a controller—it is a dynamic, adaptive power source tailored to the mechanical and thermal limitations of the motor.

When engineers size systems for performance, they often focus on motor specifications. But in reality, it is the driver that enables the motor to operate close to those specs consistently and reliably.

Summary

A stepper motor without a driver cannot perform—only with the right driver can it deliver power, speed, and precision effectively.For further questions please contact [email protected]