In modern automation, precision is no longer optional—it’s expected. That’s where the linear motor unit steps in, delivering unmatched accuracy, speed, and reliability. Whether you’re optimizing semiconductor lines or upgrading CNC systems, understanding what a linear motor is and how it works can unlock new levels of performance in your operation.

What Is a Linear Motor?

A linear motor is an electric motor that creates straight-line motion directly—without the need for mechanical transmission systems like screws, belts, or gears. Unlike rotary motors, which require conversion mechanisms, a linear motor unit produces direct linear motion by design.

Keyword: linear motor unit

Key Benefit: No mechanical conversion = less wear, more efficiency

These motors are designed around electromagnetic principles, offering high precision motion, fast acceleration, and excellent control, making them indispensable in today’s industrial automation and precision manufacturing.

How Does a Linear Motor Work?

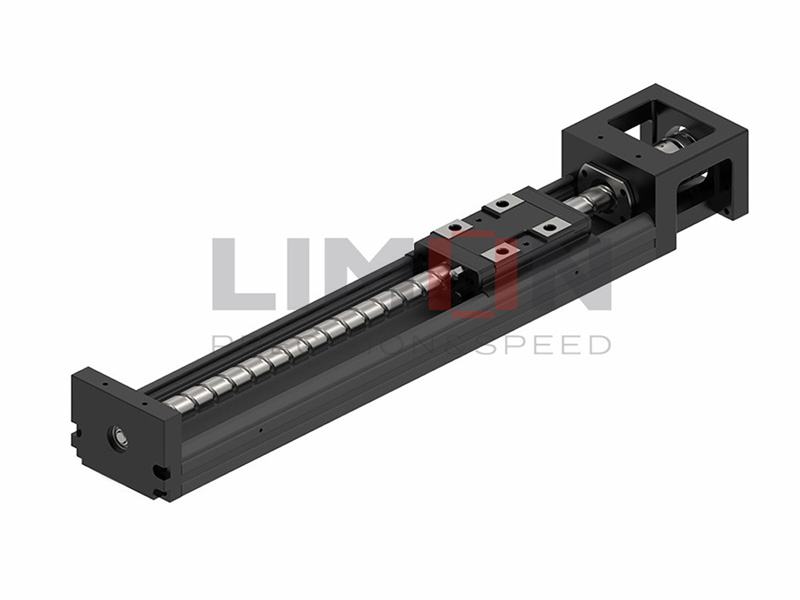

At its core, a linear motor consists of two main parts:

Primary (Stator): Contains the electromagnetic windings

Secondary (Forcer): Usually made of permanent magnets or conductive material

When electrical current flows through the stator, a magnetic field is generated, creating electromagnetic thrust along the motor’s length. This force pushes the forcer in a straight line, resulting in immediate linear movement.

No belts. No gearboxes. No screw drives. Just pure linear motion.

Types of Linear Motors and Their Applications

Not all linear motors are created equal. The right configuration depends on your load, speed, and precision requirements. Here’s a breakdown:

Iron-Core Linear Motors

High force density

Best for heavy-load applications in machine tools and packaging lines

Slight cogging may occur

Ironless Linear Motors

Smooth, cog-free motion

Ideal for semiconductor manufacturing, lab automation, and precision inspection equipment

Lightweight and highly dynamic

Tubular Linear Motors

Cylindrical, compact design

Excellent for robotics, actuators, and systems requiring high acceleration

Efficient space utilization

Where Are Linear Motor Units Used?

The linear motor unit is the driving force behind some of today’s most advanced machinery. Key industries include:

Industrial Automation: Fast, accurate pick-and-place operations

Semiconductor Equipment: Sub-micron positioning with zero backlash

Medical Devices: Smooth motion with clean operation for lab automation

CNC Machines: Rapid tool changes and precise part handling

Transportation: Maglev trains and other electromagnetic propulsion systems

Summary: Why Choose a Linear Motor Unit?

Choosing a linear motor unit means opting for:

Direct linear drive (no mechanical conversions)

High-speed, high-precision performance

Minimal maintenance (fewer moving parts)

Increased energy efficiency

Whether you’re scaling up throughput or aiming for nanometer-level precision, linear motors deliver.

Visit LIMON to explore cutting-edge linear motion solutions engineered for next-generation automation.