And Why They’re Critical to Modern Industrial Efficiency

Linear guides are the backbone of precision engineering, offering low-friction, high-load linear motion in everything from robotic arms to surgical robots. These components are engineered for speed, stability, and repeatability, making them indispensable to industries where precision equals profit.

Featured Snippet Answer

Linear guides are widely used in automation, medical devices, semiconductor manufacturing, renewable energy, aerospace, and robotics. Their advantages—precision, durability, and high load capacity—enable linear guide manufacturers to deliver optimized motion control in demanding application fields, from automated assembly lines to advanced surgical systems.

1. How Do Linear Guides Revolutionize Industrial Automation?

In industrial automation, linear guides ensure smooth, accurate motion for CNC machines, robotic arms, and conveyor systems.

Functional advantages: High rigidity, low wear, and long service life.

Use cases: Precision welding, high-speed packaging, pick-and-place systems.

Key players: Brands like THK and HIWIN manufacture linear guides that endure high loads and high duty cycles.

In the era of Industry 4.0, where uptime is gold and microsecond delays cost thousands, linear guides are the unsung heroes keeping production seamless.

2. Why Are Linear Guides Vital in Semiconductor Manufacturing?

Semiconductor manufacturing demands sub-micron accuracy. That’s where linear guides step in:

Used in wafer handling robots, lithography systems, and inspection tools.

Features like vibration damping, cleanroom compatibility, and zero-particulate operation are non-negotiable.

Industry leaders like NSK and Bosch Rexroth engineer ultra-high precision linear guide systems tailored for semiconductor fabs.

In an industry chasing nanometers, linear guides provide the mechanical stability chips need to evolve.

3. What Makes Linear Guides Critical in Medical Equipment?

In medical technology, the margin for error is zero. Linear guides provide:

Hygienic, sterilizable motion control in devices like MRI tables, robotic surgery arms, and diagnostic scanners.

Materials like stainless steel and polymer-coated surfaces from brands such as Schneeberger and IKO ensure compliance with medical-grade standards.

From diagnostics to surgery, linear guides support precise, repeatable movements—literally saving lives with every pass.

4. Can Renewable Energy Systems Function Without Linear Guides?

Short answer: no. In renewable energy, linear guides are critical to maximizing system output.

Solar panel trackers rely on linear guides to adjust angle relative to the sun.

Wind turbines use them in pitch control systems for blade alignment.

Brands like TBI Motion and PMI develop corrosion-resistant linear guides engineered for outdoor, all-weather reliability.

With the global push toward clean energy, linear guide systems have become mission-critical for efficient power generation.

5. How Do Aerospace Applications Utilize Linear Guides?

The aerospace sector pushes components to the limit—extreme temperature, speed, and stress.

Linear guides are used in:

Aircraft jigs and fixtures

Satellite deployment systems

Jet engine test platforms

Manufacturers like SKF and Thomson supply aerospace-certified linear guides that meet rigorous safety and quality standards, ensuring reliable performance during both manufacture and operation.

6. Are Linear Guides Used in Advanced Robotics?

Absolutely. In collaborative robots (cobots) and autonomous mobile robots (AMRs), linear guides deliver:

Compact, high-precision motion for joints, grippers, and linear actuators

Minimal maintenance with high-load, high-duty operation

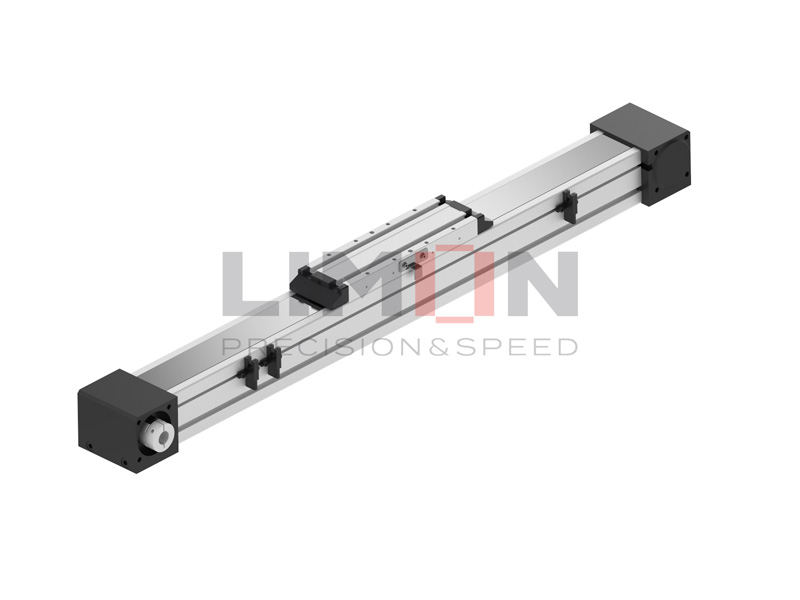

Integration by companies like LIMON, supporting logistics, electronics, and smart agriculture

Without linear guides, next-gen robotics would wobble—literally.

In Summary: Why Linear Guides Are a Cornerstone of Industrial Innovation

From semiconductor fabs to surgical theaters, linear guides provide the reliability, precision, and motion control modern industry demands. Whether you’re in energy, aerospace, or robotics, the right linear guide system can elevate your operational efficiency and output.