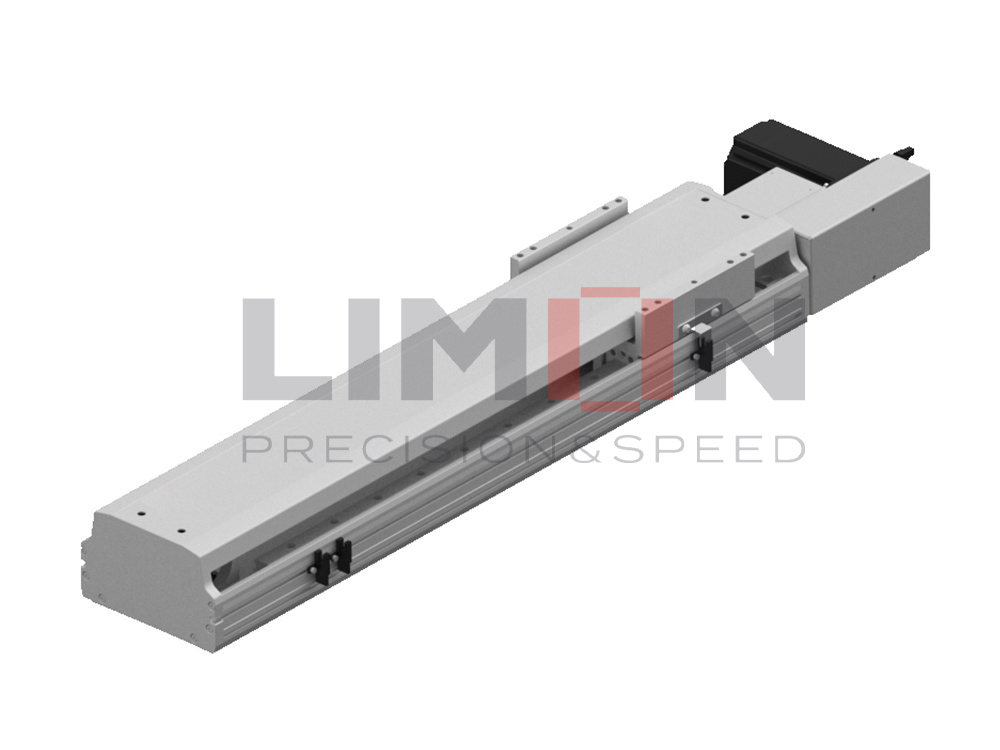

After you received your linear actuator/linear unit, it has the smoothness of industrial products, and now you might just have one thought, which is how am I supposed to use it to make its life span as long as it can. So today’s topic is going to be – how to use linear actuators, and we hope this can bring you actual benefits about how to use linear actuators correctly and save it’s life.

In the field of automation industry, linear units are called single axis linear motion devices. Because they can be combined into multi axis rectangular coordinate manipulators, such as cross combination, gantry type, etc., they are widely used. Now let’s come to the topic,how to use linear actuators when we got one according to different situation.

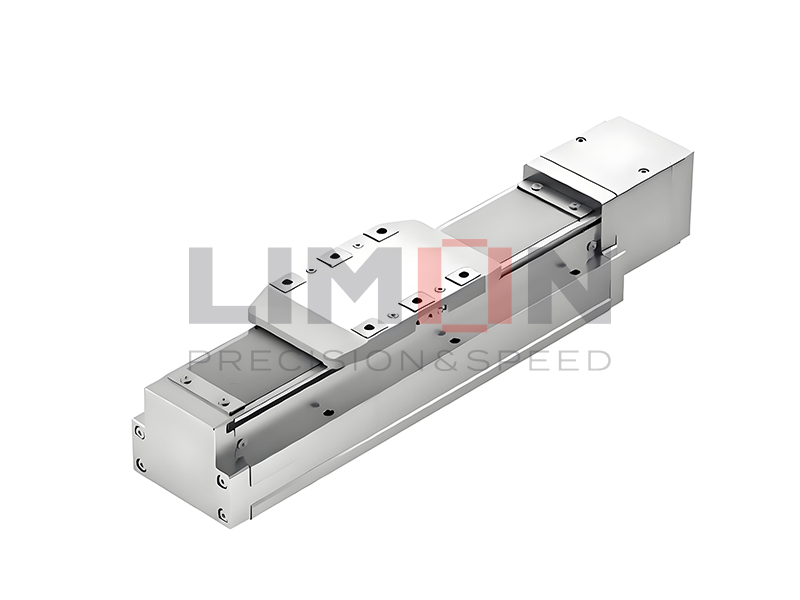

Step 1 – how to use linear actuators – requirements and preparation of installation platform:

1. During the operation of linear units, the platform will be subjected to large impact force, so the installation platform should have sufficient stiffness and stability.

2. If conditions permit, the contact area between the linear units base and the installation platform shall be increased as much as possible.

3. Please ensure that there are no foreign matters, burrs and other items on the installation platform that may hinder the installation of the module before installation.

Step 2 – how to use linear actuators – : installation steps of single axis sliding table module:

The installation mode of single axis manipulator can be divided into lock installation and lower lock installation. The appropriate installation mode can be selected according to the current situation of the workbench.

- If the locking installation is adopted, first remove the dust cover, pass the Allen screw through the body base of the single axis linear module, and lock it to the screw hole of the installation platform.

- If the lower lock installation is adopted, the screw shall pass through the installation platform and the lock shall be attached to the screw hole of the body base.

Step 3 – how to use linear actuators – : installation of single shaft linear module motor:

After receiving the linear units, please install the motor according to the corresponding motor manual. During the installing the motor, please refer to the following operation sequence:

1. If the motor is directly connected, please align the motor mounting flange hole with the ball screw shaft end; If the motor is installed by side folding, make sure that the two synchronous wheels are flush (the alignment error shall not be greater than 0.5mm).

2. Fix the mounting holes of the motor flange in turn, tighten the fastening screws of the motor output shaft and coupling, and install the dust cover after confirmation.

Step 4 – how to use linear actuators – : sensor installation and power on test:

The sensor of the linear units is also called the limit switch. Three sensors are installed in the groove on the side of the module body and placed at the position requiring fiber and test.

Step 5 – how to use linear actuators – : precision test of linear module:

After the installation of the linear units and confirming whether the operation noise and smoothness are normal, you can choose whether to measure the horizontal and vertical running parallelism of the linear units.

Generally, you don’t have to worry about problems, since the manufacturer has carried out various accuracy tests and aging tests before leaving the factory. The following is the parallelism accuracy test method of linear module for customers who need it:

1. Horizontal walking parallelism accuracy test:

- Fix the base of the linear units evenly on the precision reference platform, and set the dial indicator on the sliding seat.

- Adjust the distance from the ruler to the sliding table so that the value of the dial indicator pointer on the sliding seat from two points at both ends of the stroke to the parallel ruler is equal.

- Move the pointer in the whole stroke, and the difference between the maximum value and the minimum value of the dial indicator reading is the horizontal walking parallelism of the sliding table.

2. Accuracy test of vertical walking parallelism:

- Fix the base of the linear module evenly on the precision reference platform, and set the dial indicator on the sliding seat.

- The pointer of the dial indicator contacts the reference plane of the measuring platform and moves the pointer within the whole stroke.

- The difference between the maximum and minimum values of the dial indicator degrees is the vertical walking parallelism of the sliding table.

These are the tips of how to use linear actuators, we have introduced some methods and we hope they can be helpful. We believe you have known how to use linear actuators and we trust that you will take care of them. Usually the factory installation of the linear units is basically perfect, and the operation is simple and convenient. However if you have any questions and you would need help, we are more than happy to be here not just for how to use linear actuators, but also any other problems as long as you let us know!

2.jpg)