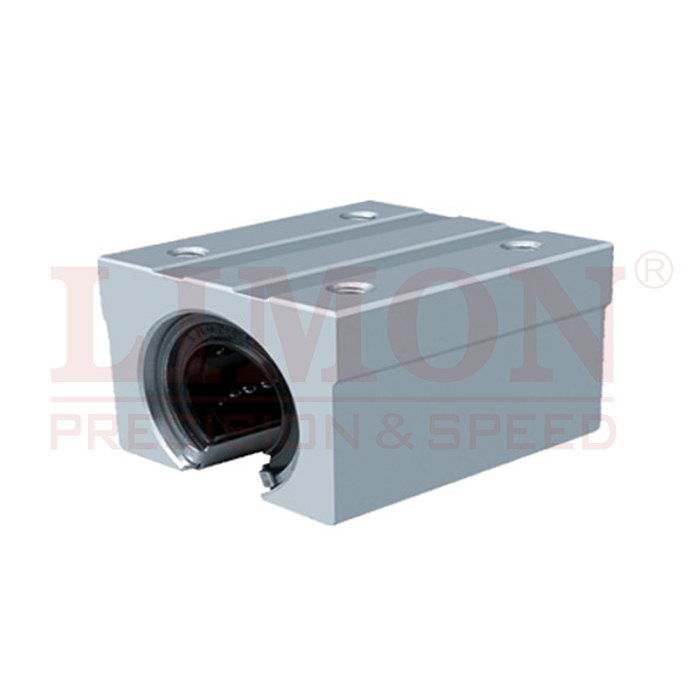

Understanding the Basic Function of Linear Motion Guide

Linear motion guides are essential components in precision machinery, enabling smooth and controlled linear movement. These guides minimize friction, enhance efficiency, and ensure stability in various industrial applications, from automation to medical equipment. Selecting the right linear guide requires careful evaluation of key factors such as load capacity, environmental conditions, and material compatibility.

The Significance of Linear Motion Guides in High-Precision Applications

Linear motion guides provide stability, accuracy, and durability in precision applications, reducing operational friction and enhancing efficiency. Their role in industrial automation, robotics, and medical devices ensures reliability, making them indispensable for high-performance systems. Choosing the right linear guide enhances productivity and system longevity.

Uncovering the Hidden Advantages: Why You Should Dive Deeper

Linear guides offer more than just smooth movement; they enhance performance, reduce maintenance, and increase system lifespan. By selecting high-quality guides from reputable linear guide manufacturers, businesses can improve efficiency and reduce downtime. These functional advantages make them ideal for various application fields, ensuring long-term operational success.

To make an informed decision, let’s explore the critical factors that influence linear guide selection.

Cost-Efficiency in the Long Run

While initial costs may vary, investing in a high-quality linear guide ensures long-term savings. Premium guides reduce wear and tear, minimize maintenance costs, and prevent unexpected failures. Companies should consider lifecycle expenses rather than just upfront prices to achieve optimal cost-efficiency. Durable materials and advanced engineering contribute to longevity, making them a cost-effective choice.

Adaptability to Diverse Environments

Different industries require linear guides that can withstand extreme conditions, such as high temperatures, humidity, or corrosive environments. Selecting guides with appropriate coatings, materials, and sealing options ensures consistent performance in various application fields. Industries like food processing, aerospace, and pharmaceuticals demand specialized linear guides to maintain precision under challenging conditions.

Compatibility with Different Materials and Systems

Linear guides must integrate seamlessly with different machinery, ensuring compatibility with materials like stainless steel, aluminum, or specialized alloys. Proper alignment with existing systems enhances efficiency, reducing installation and maintenance complexities. By working with experienced linear guide manufacturers, businesses can find solutions tailored to their specific operational needs.

Innovation and Technological Advancements

Continuous advancements in linear motion technology improve performance, efficiency, and adaptability. Modern guides incorporate smart sensors, self-lubrication mechanisms, and enhanced load-bearing capacities. These innovations optimize production processes, reduce downtime, and ensure superior operational precision in industries like robotics and semiconductor manufacturing.

Customization Options

Many industries require tailored linear guides to meet specific design and performance needs. Customizable options include size variations, specialized coatings, and load-bearing capacities. By collaborating with trusted linear guide manufacturers, businesses can obtain solutions designed to meet unique operational requirements, improving overall efficiency and reliability.

Safety and Reliability in Critical Applications

Safety is a top priority in applications such as medical devices, aerospace systems, and high-speed automation. High-quality linear guides ensure stability, reducing the risk of mechanical failures and ensuring smooth operation. Manufacturers focusing on precision engineering and rigorous testing provide reliable guides that meet strict industry standards, enhancing overall system safety.

Conclusion

Choosing the right linear guide requires balancing cost, adaptability, compatibility, innovation, customization, and safety. Investing in quality ensures long-term efficiency and operational success.