What Is Linear Guide

A linear guide is an essential component in mechanical systems, providing smooth and precise motion along a straight path. These guides are vital in industries such as automation, medical devices, and precision tools. By reducing friction and enabling stable movement, linear guides enhance both efficiency and reliability in various applications.

What Are Key Points That Matter When Selecting a Linear Guide?

When selecting a linear guide, consider factors such as load capacity, precision, type of application, environmental conditions, and available certifications. Ensure compatibility with system requirements and prioritize quality to avoid operational inefficiencies and costly replacements.

Linear Guides Manufacturers

Numerous manufacturers globally produce high-quality linear guides. Among them, LIMON stands out as a leading player in the linear motion industry. Since 2003, LIMON has focused on producing reliable, high-precision components like linear guides, ball screws, and actuators. Known for quality and innovation, LIMON serves a global market spanning over 31 countries.

Explore the sections below to delve deeper into linear guide selection and application.

List of 10 Linear Guide Manufacturers

- LIMON– Based in China, LIMON specializes in high-precision linear motion components and serves a global clientele.

- THK– A Japanese manufacturer known for durable and innovative linear motion products.

- Hiwin– A Taiwanese leader in linear guide technology offering a wide range of solutions.

- Bosch Rexroth– German precision engineering with versatile linear motion solutions.

- SKF– Swedish excellence in linear guides and motion systems.

- NSK– High-performance products from a reputable Japanese brand.

- Schneeberger– Swiss precision and engineering for industrial applications.

- IKO International– Specializes in miniature linear motion guides for compact applications.

- INA (Schaeffler Group)– Known for high-precision linear rolling bearings.

- PBC Linear– U.S.-based manufacturer focused on cost-effective, high-quality solutions.

Different Types of Linear Guides

Linear guides come in various types to meet diverse application needs:

- Regular Type: Standard linear guides for general industrial use, balancing load capacity and precision.

- Quiet Type: Incorporates noise-reduction features, ideal for medical or laboratory settings.

- Miniature Type: Compact and lightweight, suitable for space-constrained applications like 3D printing.

- Roller Type: Uses rollers instead of balls for higher load capacity and rigidity in heavy-duty applications.

Where Are Linear Guides Used?

Linear guides are widely employed across industries, including:

- Automotive: Assembly lines and manufacturing automation.

- Medical Devices: High-precision surgical equipment.

- Electronics: Semiconductor manufacturing tools.

- Packaging: High-speed and accurate labeling or sorting machines.

- Aerospace: Precision machining and testing facilities.

Their adaptability ensures they play a critical role wherever precision and stability are required.

What Certificates Do You Need to Import Linear Guides to the USA?

Importing linear guides to the U.S. may require several certifications to ensure compliance with safety and quality standards:

- ISO 9001: Quality management certification to assure high manufacturing standards.

- RoHS Compliance: Ensures products are free from hazardous substances.

- CE Marking: Mandatory for certain products entering the European and North American markets.

- UL Certification: For electrical components used in conjunction with linear guides.

Consult with manufacturers to confirm these certifications and avoid import delays.

How Much Will the Importation Cost to the USA?

The cost of importing linear guides depends on:

- Product Price: Typically ranges from $30 to $300 per guide, depending on type and specifications.

- Shipping Costs: Vary based on origin, weight, and delivery terms (e.g., FOB or CIF).

- Customs Duties and Taxes: Import duty rates in the U.S. for machine components usually range between 0-5%.

- Other Fees: Handling charges and brokerage fees add to the final cost.

Obtaining quotes from multiple suppliers can help control expenses.

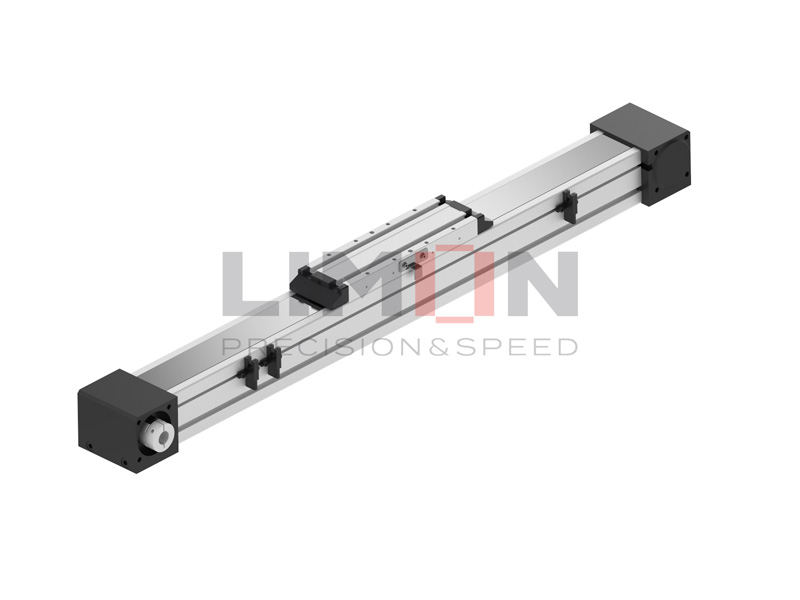

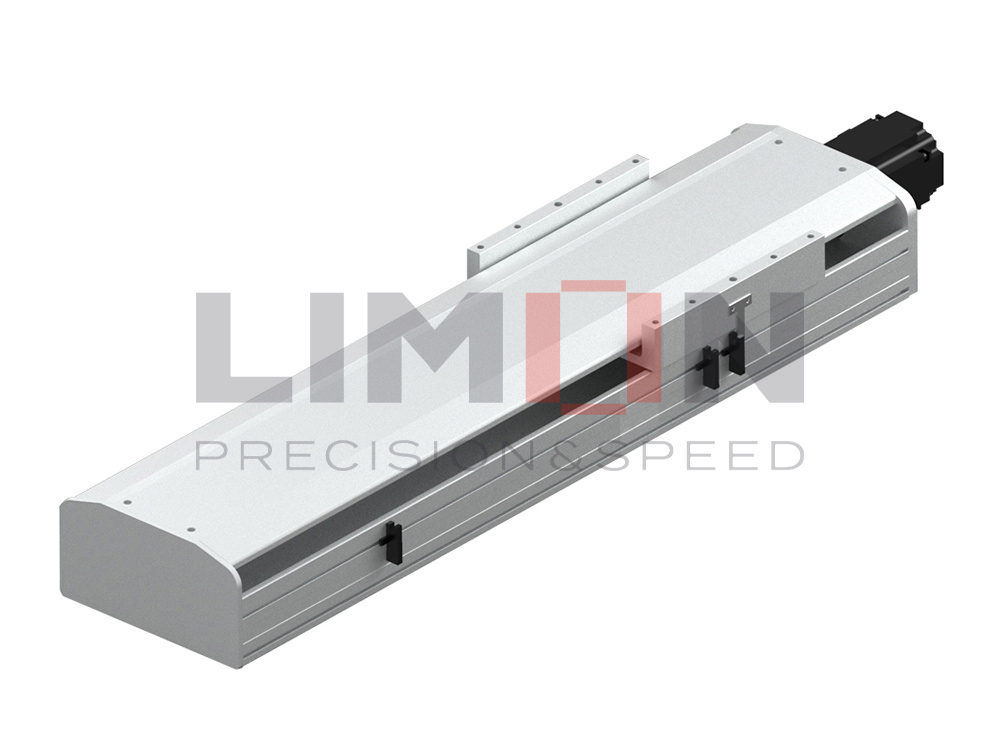

LIMON’s Linear Guides Introduction

LIMON offers a wide range of linear guides tailored to meet diverse industrial needs. Products such as the H Series provide self-aligning capability, high rigidity, and smooth operation. The QH Series, with its low-noise design and self-lubricating technology, is ideal for high-speed, high-precision applications.

LIMON’s robust quality control ensures every guide meets international standards, making them a reliable choice for global industries.

Conclusion

Choosing the right linear guide involves understanding application requirements, evaluating manufacturers, and ensuring compliance with certifications. With products like LIMON’s high-precision guides, businesses can achieve reliable and efficient operations tailored to their needs.