How to reduce ball screw noise?

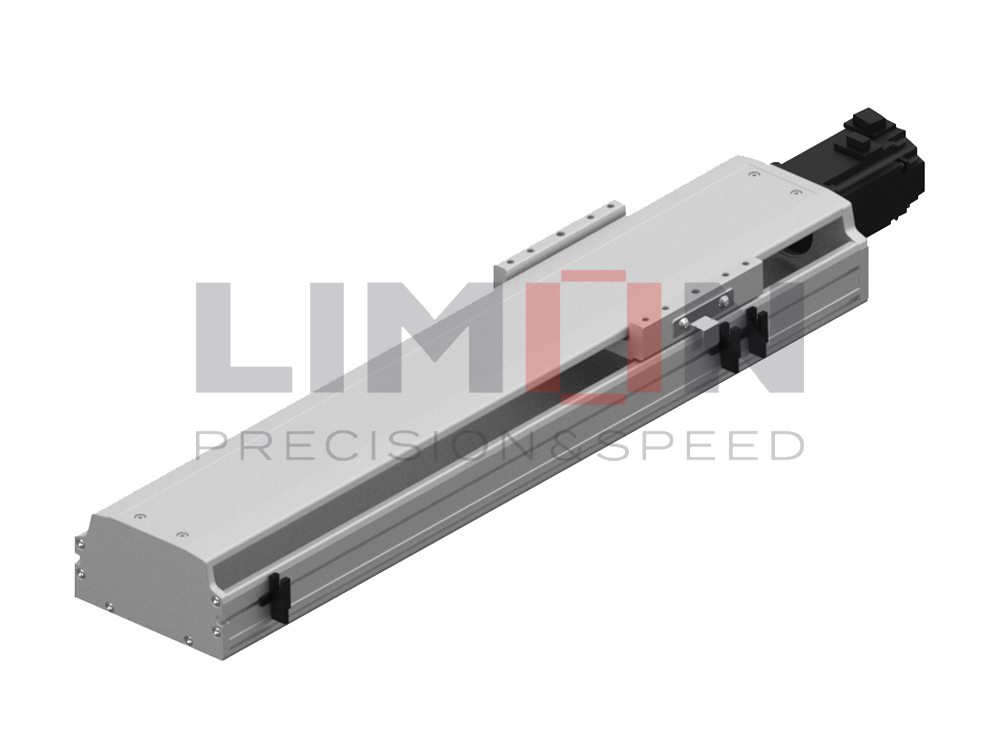

When grappling with ball screw noise concerns, especially in precision applications like those utilizing ball screw actuators or ball screw linear actuators, addressing this issue becomes crucial for maintaining a quiet and efficient operation.

In the discourse of ball screw vs lead screw mechanisms, noise reduction is often a critical factor in decision-making. While lead screws may produce more audible noise due to sliding contact, ball screws, especially in ball screw CNC systems, are preferred for their ability to minimize noise during linear motion.

Identifying Causes: Unraveling the Sources of Ball Screw Noise

To initiate the process of reducing ball screw noise, understanding the underlying causes is essential. Factors such as lead screw vs ball screw design, wear and tear, or improper installation can contribute to increased noise levels. Identifying these issues is the first step towards a quieter operation.

Maintenance Matters: The Crucial Role of Ball Screw Nut and Bearing

Considering the role of components like the ball screw nut and ball screw bearing is vital in noise reduction efforts. Proper maintenance, lubrication, and periodic checks on these components can contribute significantly to minimizing friction-induced noise, addressing potential concerns that might lead to ball screw repair.

Precision Leads to Silence: The Role of Lead in Noise Reduction

In the context of ball screw lead, selecting an appropriate lead is not only crucial for precision but can also impact noise levels. Smaller leads often contribute to smoother motion and reduced noise, especially in applications where noise reduction is a priority.

In conclusion, achieving a quieter operation in ball screws is not only beneficial for operator comfort but is also indicative of a well-maintained and optimized system. Whether in ball screw actuators or ball screw linear actuators, understanding the nuances of noise reduction in the lead screw vs ball screw debate is key. By addressing factors like ball screw repair, ball screw nut, ball screw bearing, and ball screw lead, you can effectively silence the hum and ensure a smoother, quieter operation in your precision linear motion system.