Why Ball Screws Are Critical for CNC Machining

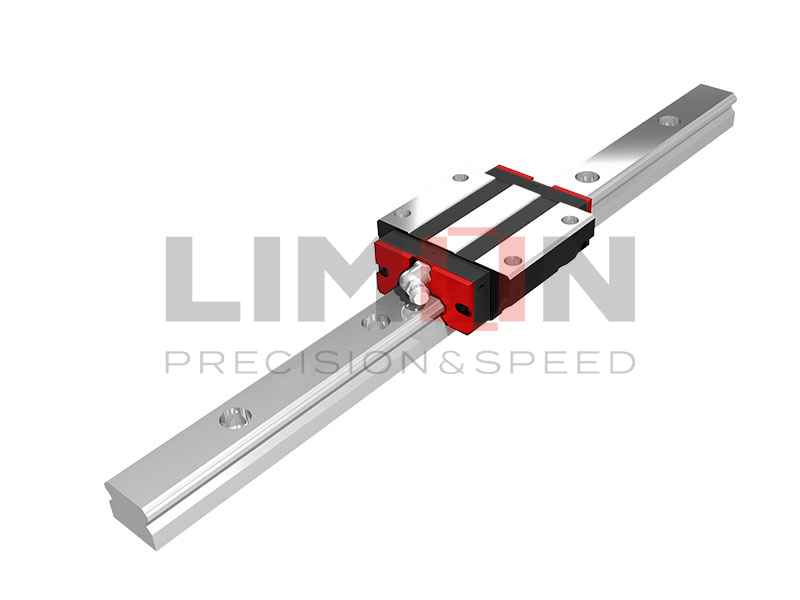

Every CNC machining operation relies on precise linear motion, and ball screws deliver this with unmatched accuracy. Their rolling ball mechanism minimizes friction, ensuring smooth, consistent performance.

Compared to other motion control options, ball screws excel in:

- High precision with minimal backlash.

- Durability for heavy-duty applications.

- Energy efficiency, saving operational costs.

For more on why ball screws dominate CNC applications, check out this article.

Determine Your CNC Machining Requirements

Every CNC machine is different, and so are its needs. When choosing a ball screw, consider:

- Load capacity: How much weight will it handle?

- Speed: Do you prioritize speed over precision, or vice versa?

- Environment: Will it operate in a clean room or a dusty factory floor?

For precision machining, I recommend ground ball screws, while rolled ball screws work well for general tasks. Not sure which type fits your needs? This ground vs. rolled ball screw guide has you covered.

The Role of Size and Lead in Ball Screw Performance

Choosing the correct ball screw size and lead (pitch) directly impacts your CNC machining efficiency:

- Diameter: Larger diameters support heavier loads but can limit speed.

- Lead: A smaller lead provides higher precision; a larger lead ensures faster movement.

For example, if you’re machining small, intricate parts, opt for a finer lead. For rapid prototyping, go with a higher lead screw.

Focus on Material and Coating

Durability is non-negotiable in CNC machining. Most ball screws are made from hardened steel or stainless steel for longevity. Consider coatings like:

- Chrome plating for wear resistance.

- Anti-corrosion layers for humid environments.

Proper material selection ensures your ball screw withstands harsh conditions while maintaining peak performance.

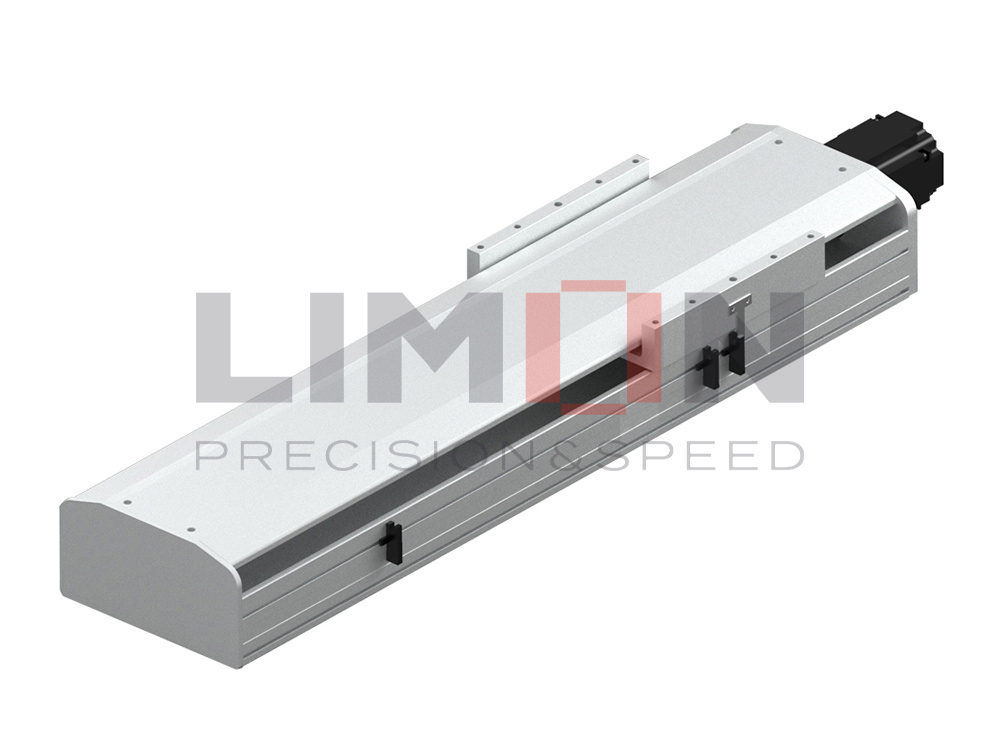

Support Components: Don’t Overlook These Essentials

A ball screw is only as good as its support system. Ensure your CNC machine is equipped with:

- High-quality bearing blocks to stabilize motion.

- Effective lubrication systems to reduce friction and extend lifespan.

For tips on setting up the ideal support system, visit this lubrication guide.

Balancing Cost and Value

While premium ball screws come with a higher price tag, they deliver superior value through:

- Increased machine accuracy.

- Reduced maintenance needs.

- Lower energy consumption.

Investing in high-quality ball screws ensures long-term savings and optimal performance for your CNC machining operations.

Partnering with Trusted Suppliers

A reliable supplier can make the selection process seamless. Look for suppliers who:

- Offer a wide range of ball screws tailored to CNC needs.

- Provide technical support and customization options.

- Have a proven track record of quality and service.

For trusted recommendations, explore this supplier directory.

Why Ball Screws Are the Backbone of CNC Machining

Choosing the right ball screw is more than a technical decision—it’s a strategic move to enhance precision, efficiency, and durability in your CNC machining operations. By understanding your needs and partnering with the right supplier, you can unlock your machine’s full potential.

Need Expert Guidance? Let’s Talk!

Not sure where to start? Contact me for personalized advice on selecting the perfect ball screw for your CNC machine. Or, explore our comprehensive ball screw catalog for more options.