Inaccurate motion control leads to poor product quality, wasted energy, and production failures. Servo motors solve this with high precision, feedback control, and efficiency. Discover how they operate.

Servo motors are precision-controlled motors that use feedback systems to achieve accurate motion control in automation, robotics, and industrial machinery. Their internal design ensures efficiency, torque, and positional accuracy.

Read on to understand their structure and industrial roles.

Inside a Servo Motor

Servo motors are electromechanical devices designed to deliver precise angular or linear motion through closed-loop control. Unlike simple motors, servo motors combine mechanical, electrical, and control elements into one integrated system to ensure consistent performance and feedback-based accuracy.

A typical servo motor contains the following main components:

Stator and Rotor: The stator generates a rotating magnetic field, while the rotor is the moving part that follows this field.

Encoder or Resolver: Positioned on the shaft, it provides real-time feedback on position, speed, and direction to the controller.

Gearbox (Optional): Some servo motors include a gear train to reduce speed and increase torque.

Controller Interface: Receives command signals (e.g., voltage, PWM, or digital commands) and adjusts motor behavior accordingly.

Drive or Amplifier: Modulates voltage or current based on feedback, ensuring precise response to input signals.

When a signal is sent to the motor, the internal circuit compares it with the encoder’s feedback. The difference between the target and actual position triggers corrective movement, resulting in responsive, accurate positioning.

This continuous feedback loop is what distinguishes servo motors from open-loop motors such as steppers, making them indispensable for automation and high-precision systems.

Servo Motor Control

Servo motors operate using closed-loop control systems—meaning they constantly compare actual performance with the target command and adjust in real time. This level of control enables precise positioning, velocity, and torque regulation.

The control system typically consists of:

Command Input: This can be a digital signal, analog voltage, or a pulse-width modulation (PWM) signal. It defines the desired motion—whether angle, speed, or position.

Controller or Servo Drive: It processes the input command and compares it with the feedback signal from the encoder or resolver. If there’s any deviation (called “error”), the controller modifies the motor input to correct it.

Feedback Device: Encoders or resolvers mounted on the motor shaft monitor speed and position. These devices send continuous updates to the controller, creating a dynamic feedback loop.

Power Amplification: The controller uses the error signal to drive power amplifiers, which adjust current or voltage to the motor to achieve the desired output.

Tuning and PID Control: Many systems use PID (Proportional-Integral-Derivative) control loops to ensure smooth acceleration and deceleration, eliminate overshoot, and minimize steady-state error.

This precise feedback mechanism allows servo motors to maintain high performance even under load variations, sudden stops, or speed changes—making them ideal for demanding applications.

Types of Servo Motors

Servo motors come in various forms, each tailored for specific performance criteria, size constraints, and control complexity. The most common classifications include:

1. AC Servo Motors

These operate on alternating current and are known for their high-speed performance, precise control, and efficient power usage. They are often used in CNC machinery, robotics, and conveyor systems. They offer:

High torque-to-inertia ratio

Good heat dissipation

High accuracy with optical encoders

2. DC Servo Motors

Operating on direct current, DC servo motors are simpler and more affordable. They are commonly used in smaller-scale automation, RC vehicles, and mechatronics systems. Key traits include:

Simple control circuitry

Moderate efficiency

Ideal for low-cost, low-power applications

3. Brushless Servo Motors (BLDC)

These use electronic commutation instead of brushes, offering extended lifespan and lower maintenance. Widely used in drones, medical equipment, and precision tools. Advantages include:

High speed and reliability

No brush wear

Low electromagnetic interference

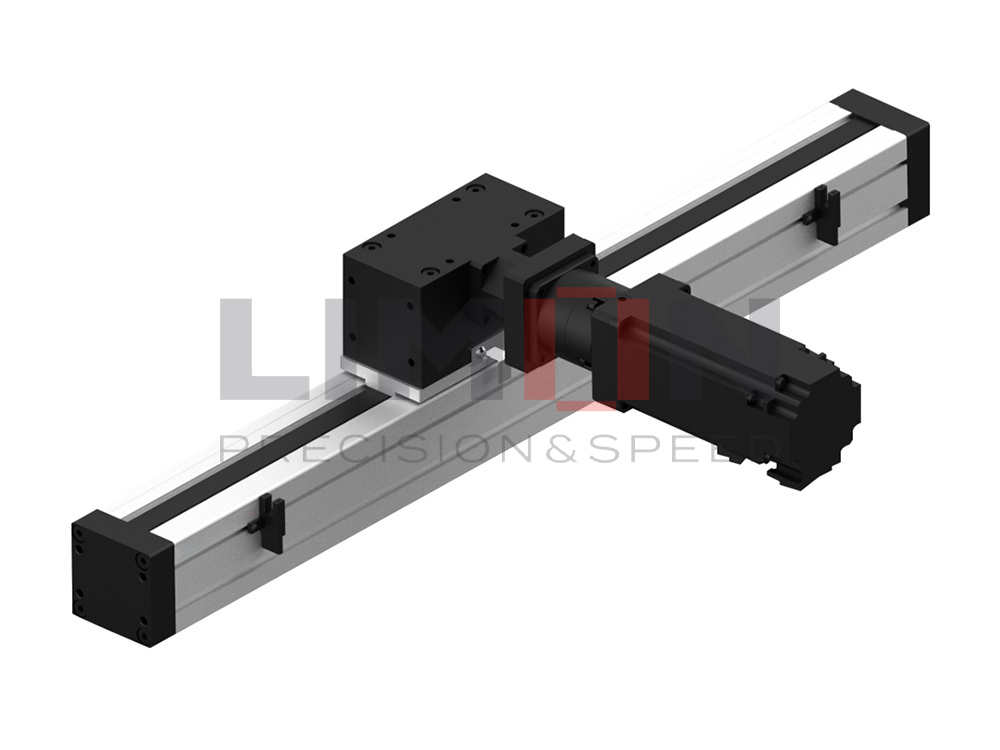

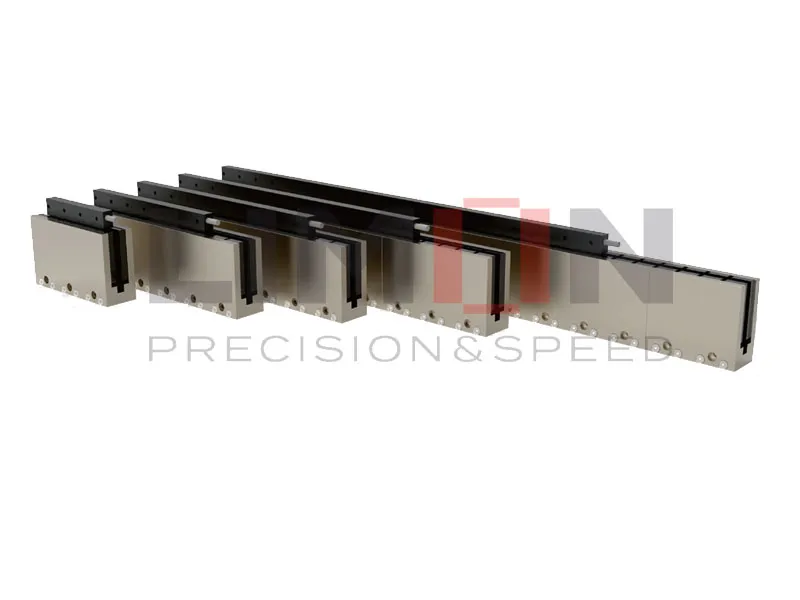

4. Linear Servo Motors

Instead of rotating, linear servo motors produce direct linear motion. They are ideal for semiconductor manufacturing and high-speed cutting where direct translation is required.

5. Digital Servo Motors

Equipped with microcontrollers, digital servos offer better torque consistency, fine-tuned control, and programmability. Used in high-end robotics and aerospace systems.

The selection of servo motor type depends on your application’s requirements for precision, speed, environment, and budget.

Comparison Table: AC vs DC vs BLDC Servo Motors

| Characteristic | AC Servo Motors | DC Servo Motors | BLDC Servo Motors |

|---|---|---|---|

| Supply Type | Alternating current | Direct current | Direct current |

| Typical Voltage | 120 to 480 VAC | 12 to 72 VDC | 12 to 48 VDC |

| Efficiency | Lower | Moderate | Higher |

| Brushes | Yes | Yes | No |

Servo Motor Applications

Servo motors are the backbone of precision motion control in various industries. Their ability to deliver accurate, repeatable, and efficient motion makes them ideal for both simple and complex tasks.

1. Industrial Automation

Used in assembly lines, packaging, and robotic arms, servo motors provide controlled motion for pick-and-place systems, presses, and indexing tables. Their high reliability under continuous duty is a major asset.

2. CNC Machinery

Servo motors power axes in CNC routers, lathes, and milling machines, where micron-level positioning and consistent speed are critical to product quality and tool longevity.

3. Robotics

Robotic systems rely heavily on servo motors for joint control, gripper actuation, and wheel rotation. Their ability to respond in real time makes them perfect for collaborative robots (cobots) and industrial robotics.

4. Aerospace

In aviation systems, servo motors are used in control surfaces, simulation equipment, and precision actuators. Their high torque, responsiveness, and reliability are essential in mission-critical scenarios.

5. Medical Equipment

Servo motors drive surgical robots, imaging tables, and infusion pumps. Their low noise, precision, and ability to function in clean environments are vital in healthcare technologies.

6. Printing and Labeling

Used in paper feeders, label applicators, and registration systems, servo motors enable high-speed, precision motion with minimal error—even under high throughput.

Servo motors continue to evolve in sophistication, expanding into autonomous vehicles, renewable energy systems, and even humanoid robots.

Summary

Servo motors deliver efficient, accurate, and real-time controlled motion—making them essential across automation, CNC, medical, and aerospace industries.For further questions please contact [email protected]