Imprecise motion leads to mechanical wear, increased energy use, and costly failures. A linear bearing solves this by guiding motion with accuracy and minimal friction. Here’s how it works.

A linear bearing supports motion in a straight line by reducing friction between two surfaces. It ensures precision, smoothness, and load capacity in various industrial and mechanical applications.

Let’s explore how this essential motion component operates and benefits multiple industries.

How Does a Linear Bearing Work?

A linear bearing is a mechanical component that allows motion along a single axis with minimal friction. It functions by providing a low-resistance interface between a moving part and a fixed guide, usually a rail or shaft.

There are two main working principles:

Rolling contact (e.g., ball or roller bearings): Steel balls or rollers circulate between the bearing and shaft, significantly reducing friction.

Sliding contact (e.g., plain or sleeve bearings): Low-friction materials like PTFE or bronze glide over the guide surface.

As the shaft or rail moves, the bearing either rolls or slides along it, keeping the moving part aligned while supporting radial or axial loads. This design allows for highly efficient, smooth, and precise linear motion, essential in everything from 3D printers to aerospace tooling.

Linear bearings can be open or closed type, sealed or unsealed, and often include retainers or cages to maintain ball alignment and spacing, contributing to smoother operation and longer service life.

How Does a Linear Bearing Work Across Industrial Applications?

In industrial applications, linear bearings play a critical role in enabling controlled, repeatable motion. They are widely used in systems where components need to move back and forth reliably under varying loads and speeds.

Key Application Areas:

CNC Machinery: Enables accurate movement of cutting tools and worktables.

3D Printing: Guides the printer head or build platform with minimal resistance.

Automation & Robotics: Powers high-speed pick-and-place systems, conveyors, and robot axes.

Medical Devices: Ensures smooth, silent movement in imaging and diagnostic systems.

Packaging & Assembly Lines: Maintains precise product placement and handling speeds.

Industrial environments often demand high repeatability and low friction over long durations. Linear bearings help maintain productivity while minimizing energy consumption and wear. Sealed versions are commonly used in dusty or corrosive settings to extend bearing life and reduce maintenance intervals.

Linear Bearing Types

There are several types of linear bearings, each designed to meet specific load, speed, and environmental requirements:

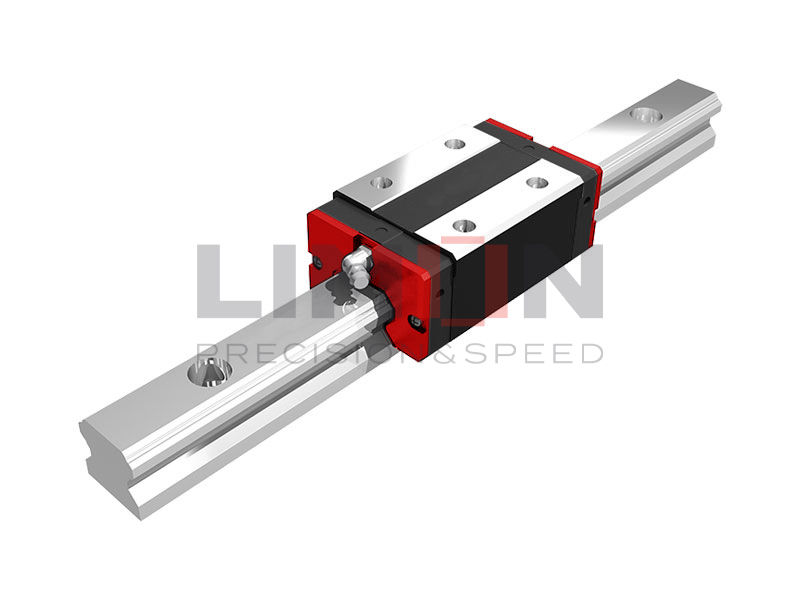

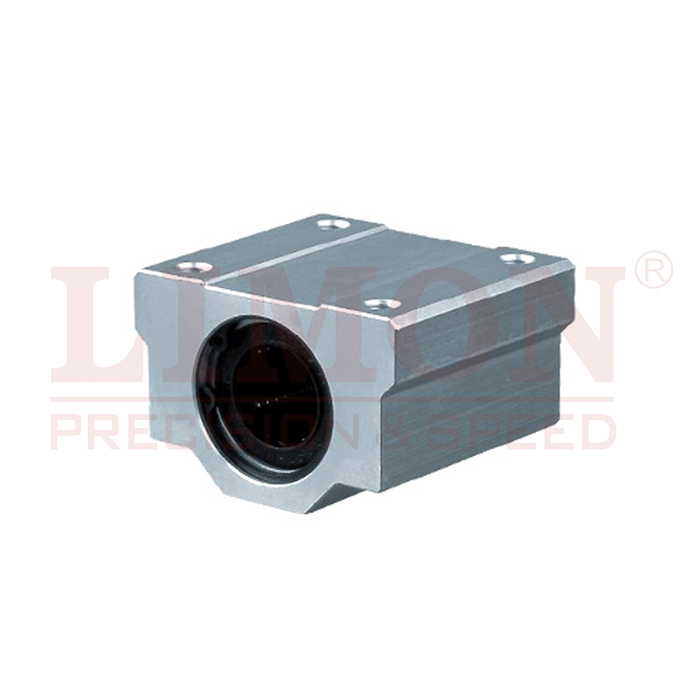

1. Linear Ball Bearings

Feature recirculating steel balls in a cage or retainer. These bearings slide along a hardened shaft and are known for high precision and low friction. They’re commonly found in CNC machines and lab automation.

2. Linear Roller Bearings

Use cylindrical rollers instead of balls, distributing load over a larger surface. They offer higher load capacity and rigidity, making them ideal for heavy-duty applications like metal forming machines.

3. Plain or Sleeve Bearings

No rolling elements—these rely on sliding contact. Made from materials such as bronze, plastic, or composites. They are simple, durable, and suitable for dirty or corrosive environments.

4. Air Bearings

Use a thin film of compressed air to eliminate contact between surfaces. These provide near-zero friction and are used in semiconductor, optics, and metrology systems.

5. Magnetic Bearings

Rely on magnetic levitation to achieve contactless linear motion. Ideal for cleanrooms, they eliminate wear and vibration.

Each type serves a unique purpose. Choosing the right one depends on factors such as load, environment, speed, cost, and required precision.

What Are the Advantages of Linear Bearings?

Linear bearings offer multiple benefits that make them a go-to solution for guiding motion in modern machinery:

1. Low Friction

Rolling or sliding action reduces friction dramatically, resulting in smooth, efficient motion and reduced energy consumption.

2. High Accuracy

Linear bearings maintain alignment with minimal play, allowing for micron-level positioning—essential for high-precision systems like laser cutters and 3D printers.

3. Durability

Engineered from high-strength materials such as chrome steel or engineered polymers, linear bearings withstand prolonged use under continuous loads.

4. Versatility

Available in various forms (e.g., open/closed, flanged/cylindrical), they adapt to wide-ranging design needs, from compact automation to heavy manufacturing.

5. Maintenance-Friendly

Sealed versions protect from dust and contamination, while self-lubricating designs minimize downtime.

6. Compact Design

Even in compact machines, linear bearings provide strong load support with minimal space requirements.

By reducing downtime and enhancing performance, linear bearings add long-term value to any motion system.

How Long Do Linear Bearings Last?

The service life of a linear bearing depends on multiple variables, including:

Load: Heavier loads shorten bearing life due to increased contact stress.

Speed and Acceleration: Higher speeds can increase wear or cause overheating.

Lubrication: Proper lubrication prevents metal-to-metal contact and reduces wear.

Contamination: Dust, moisture, and chemicals can accelerate failure unless properly sealed.

Alignment: Misalignment increases uneven wear, leading to early breakdown.

Under ideal conditions—with proper alignment, lubrication, and load limits—a high-quality linear ball bearing can last for 10,000 to 20,000 km of travel. Self-lubricating sleeve bearings may last even longer in slow-speed, dirty environments.

Some manufacturers provide life-expectancy calculations based on dynamic load ratings (C), expected stroke length, and duty cycle. Following recommended installation and maintenance practices ensures that linear bearings achieve or exceed their rated life span.

Summary

Linear bearings guide motion with low friction and high precision—enhancing the performance, reliability, and efficiency of modern machinery.For further questions please contact [email protected]