Mechanical systems lacking precision and efficiency lead to production delays, excess energy usage, and increased downtime. Ball screws offer accurate, smooth motion to solve these issues. Learn how.

Ball screws convert rotary motion into linear movement with high efficiency and precision. Used in a wide range of industrial equipment, they reduce friction, enhance load capacity, and extend operational life.

Explore the working principles and real-world uses of ball screws below.

How Does a Ball Screw Work?

Ball screws are precision mechanical devices designed to translate rotational motion into linear motion using rolling ball bearings. Unlike traditional lead screws, which rely on sliding friction between threads, ball screws incorporate a ball nut and recirculating ball bearings that move along the helical grooves of the shaft.

The core mechanism involves:

A screw shaft with helical grooves (threaded like a bolt),

A ball nut containing internal matching grooves, and

A series of steel balls circulating in the space between the nut and shaft.

As the screw rotates, the balls roll between the nut and shaft, carrying the load and converting torque into linear movement. After completing their path, the balls are redirected back into the circuit through return tubes or deflectors, enabling continuous motion.

This rolling contact results in very low friction (efficiency of up to 90%) and extremely accurate positioning—essential in precision machining, robotics, and other automation applications.

Why Use A Ball Screw?

The use of ball screws in industrial design stems from their superior performance characteristics over other linear motion systems. Here are the core benefits:

1. High Efficiency

With rolling elements replacing sliding contact, ball screws offer much higher mechanical efficiency—typically over 90%. This means less torque is required to achieve the same force, improving energy savings and reducing motor demands.

2. Accuracy and Repeatability

Ball screws enable precise positioning, often within microns, making them ideal for CNC machines, robotic arms, and inspection equipment. Their ability to eliminate backlash through preloading enhances repeatability in demanding environments.

3. Load Capacity and Rigidity

The contact area of the balls with the grooves allows ball screws to carry significant loads while maintaining structural rigidity. They’re suitable for vertical loads and long-travel setups under dynamic conditions.

4. Long Lifespan

Thanks to low friction and minimal wear, ball screws last longer than lead screws. Proper lubrication and environmental sealing can further extend service life even under continuous duty.

5. Smooth Motion and Low Noise

The smooth rolling motion reduces vibration and noise, making ball screws suitable for sensitive applications such as semiconductor or medical equipment.

Choosing ball screws ensures performance, precision, and durability in a wide variety of motion control systems.

What Are Ball Screws Used For?

Ball screws are used extensively across modern industries where controlled linear motion is critical. Below are some of the most common application categories:

1. CNC Machines

Whether it’s milling, turning, grinding, or EDM machines, ball screws enable precise tool positioning and smooth axis motion. Their accuracy and stiffness allow high-speed machining with minimal error margins.

2. Semiconductor Equipment

In wafer handling and precision positioning platforms, ball screws contribute to micron-level accuracy while operating in cleanroom environments with low dust and noise.

3. Medical Devices

Imaging tables, surgical robots, and diagnostic equipment use ball screws for their smooth motion and positioning precision—vital for patient safety and comfort.

4. Automotive Industry

Ball screws assist in dynamic assembly lines, robotic welding arms, and quality control inspection systems requiring high-duty cycles and reliability.

5. Aerospace and Defense

Flight simulators, control systems, and satellite equipment utilize ball screws due to their precision, durability, and ability to function under extreme conditions.

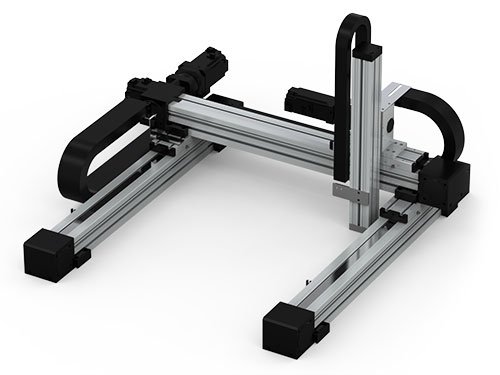

6. Industrial Automation

Pick-and-place units, packaging machines, and robotic gantries benefit from the consistent performance and longevity of ball screw mechanisms.

No matter the field, ball screws enable motion systems to deliver precise, repeatable performance under load, over long distances, and at variable speeds.

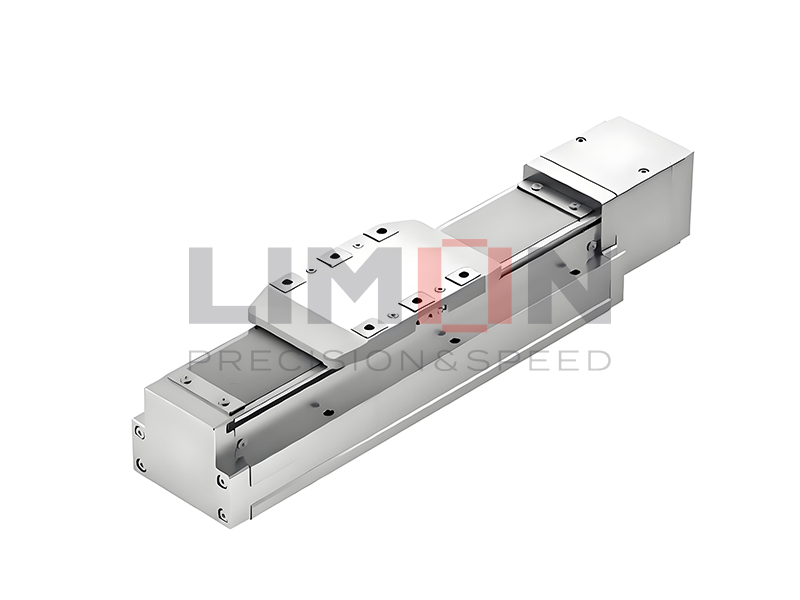

Physical Properties Of A Ball Screw

Understanding the physical makeup of a ball screw is crucial for selecting the right model for an application. Key components and properties include:

1. Shaft

Usually made from hardened alloy steel or stainless steel, the screw shaft features precision-ground or rolled helical grooves. The shaft diameter affects load capacity and stiffness.

2. Nut

The ball nut houses the ball circulation system and matches the groove profile of the shaft. Some designs offer flanged ends or preloaded dual nuts for zero backlash.

3. Balls

The recirculating balls are typically made of hardened chrome steel. Their diameter and quality affect efficiency, noise, and durability.

4. Lead and Pitch

The lead defines the distance the nut moves per revolution of the screw. Smaller leads offer higher resolution but lower speed, while larger leads offer speed but reduce mechanical advantage.

5. Preload

Preloading ball screws eliminates axial play, enhancing stiffness and accuracy. This is achieved by using oversized balls or dual-nut designs.

6. Lubrication and Seals

Proper lubrication—oil or grease—minimizes wear and maintains efficiency. Optional wipers or bellows protect against contamination.

These design elements work together to provide the reliable and smooth motion characteristics that define modern ball screw systems.

How to Select a Ball Screw

Choosing the right ball screw for an industrial application involves several critical factors. Here’s a checklist to guide the selection process:

1. Load Requirements

Calculate the axial and radial loads the ball screw will encounter. Choose a model rated for the maximum dynamic and static loads with an appropriate safety factor.

2. Travel Length

Determine the stroke distance needed. Ball screws can be custom-cut or specified in standard lengths. Consider deflection for longer screws to avoid whip.

3. Speed and Acceleration

High-speed applications require higher lead values and properly rated bearings to reduce inertia. Check the critical speed of the screw to avoid vibration.

4. Accuracy Class

Ball screws are available in different precision grades (e.g., C7, C5, C3). Applications like CNC or semiconductor systems may require C5 or C3 for fine motion control.

5. Environment

Consider exposure to dust, moisture, temperature extremes, or corrosive chemicals. Stainless steel and protective covers may be necessary.

6. Preload Needs

Zero-backlash or high-precision applications benefit from preloaded nuts, which increase stiffness but may add cost and friction.

7. Mounting and Support

Ensure the screw matches your machine’s support system (e.g., fixed–fixed, fixed–floating) and that end machining aligns with your bearing blocks.

8. Budget and Availability

Finally, balance cost with performance. For example, rolled ball screws are more affordable and suitable for general automation, while ground screws are best for high-precision tasks.

Consulting manufacturers or engineering specialists ensures optimal integration with minimal trial and error.

Summary

Ball screws deliver high-performance, low-friction linear motion—perfect for precision-driven industrial automation and demanding mechanical applications.For further questions please contact [email protected]