Upfront Costs: Comparing Ball Screws to Alternatives

When evaluating ball screws against alternatives like lead screws or rack-and-pinion systems, the initial price tag might seem steeper. However, it’s important to view this cost through the lens of long-term savings and performance.

Why Ball Screws Are More Expensive Initially

The ball screw is built with precision-engineered materials and high-quality components. These factors contribute to their higher upfront cost compared to alternatives such as lead screws.

- Lead Screws: Cheaper but less durable and precise.

- Rack-and-Pinion Systems: Typically bulkier and less efficient than ball screws.

1.2 Precision and Accuracy for Long-Term Gains

If your business involves high-precision tasks such as CNC machining or robotics, investing in ball screws will provide more value over time due to their unmatched accuracy and repeatability.

For a detailed breakdown of ball screws vs. lead screws, check out this comparison guide.

Operational Efficiency: Why Ball Screws Are Worth the Cost

Over time, ball screws justify their higher cost through operational efficiency. Let’s break down the benefits:

2.1 Energy Efficiency: Reduce Operational Costs

Ball screws use rolling elements that reduce friction significantly compared to alternatives. This results in less energy consumption and lower operational costs in the long run.

2.2 Reduced Wear and Tear

Because of their low friction design, ball screws experience less wear and tear. This prolongs their lifespan, saving you on replacement and maintenance costs.

2.3 Consistent Performance Over Time

In high-performance environments such as robotics, ball screws maintain their accuracy and efficiency, ensuring consistent results over time, which reduces downtime and increases productivity.

For more on the energy-saving potential of ball screws, read this article on energy-efficient montion systems.

Maintenance Costs: Longevity That Pays Off

While ball screws do require maintenance, the cost is minimal compared to the long-term benefits they provide. Here’s a breakdown of typical maintenance needs:

Regular Lubrication and Care

Proper lubrication is essential to maintaining smooth operation. However, many ball screws come with integrated lubrication systems, reducing manual maintenance.

Minimal Downtime for Repairs

Because ball screws are more durable and have lower wear rates, they don’t require frequent repairs or replacements, minimizing downtime and keeping your production line moving smoothly.

Inspection and Monitoring

Regular inspections are important but not costly, and help prevent major issues from arising. When maintained correctly, ball screws last longer than most alternatives.

For more maintenance tips, check out our comprehensive ball screw maintenance guide.

Scalability and Adaptability for Growing Businesses

As your business scales, the demands on your machinery and systems evolve. Ball screws are adaptable, making them a smart investment for long-term growth.

High Load Capacity

Ball screws can handle high loads without sacrificing precision, which is vital as production scales up.

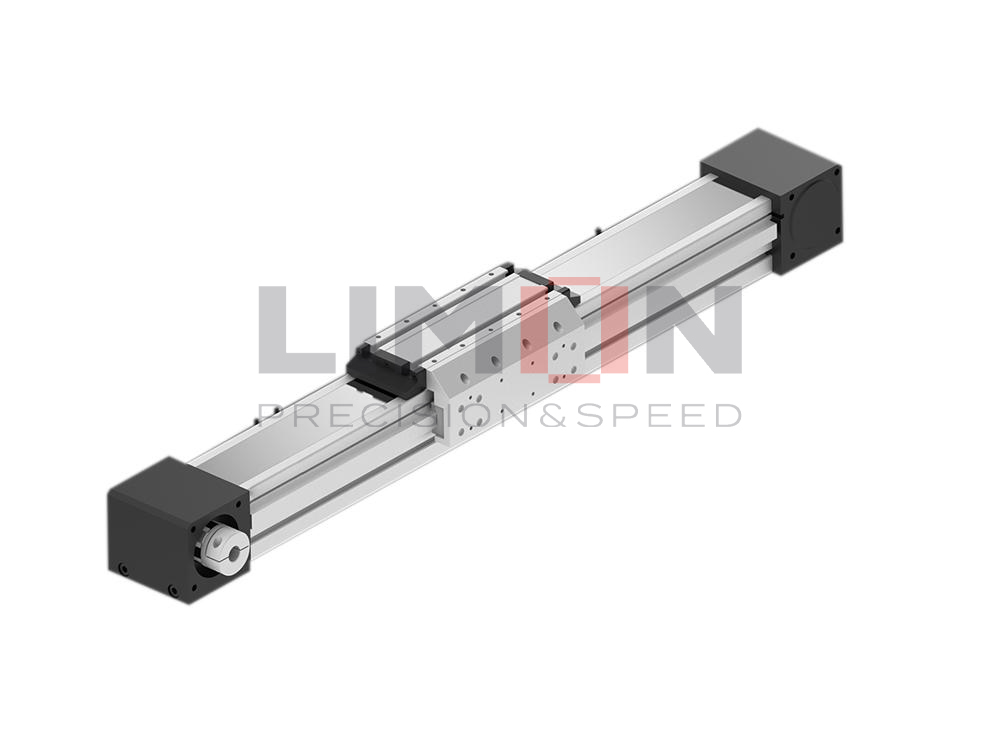

Custom Configurations for Varying Needs

Whether you need compact designs for micro-applications or larger configurations for industrial machinery, ball screws can be customized to fit your evolving needs.

Future-Proof Technology

With the integration of technologies like predictive maintenance and smart sensors, ball screws are adaptable to the latest trends in automation and robotics.

Explore scalable ball screw solutions in our product catalog.

Industries That Gain the Most from Ball Screws

Ball screws are perfect for industries that demand precision, efficiency, and reliability. These industries benefit the most:

- CNC Machining: Accuracy is essential in precision manufacturing.

- Robotics: Smooth, efficient motion is key for automation systems.

- Aerospace: High-strength ball screws endure extreme conditions.

- Medical Devices: Micron-level accuracy ensures successful operations and diagnostics.

To see how ball screws are used across industries, check out this article on ball screw applications.

Final Verdict: Are Ball Screws Worth the Investment?

When you factor in precision, durability, and energy savings, ball screws are an excellent investment for businesses that require high-performance systems. Here’s why they’re worth the cost:

- Precision and Accuracy: Perfect for demanding applications.

- Longer Lifespan: Reduced maintenance and replacement costs over time.

- Operational Efficiency: Lower energy costs and consistent performance.

Investing in ball screws is a forward-thinking decision that will pay off in the form of reliable, efficient, and long-lasting machinery.