What Is a Ball Screw?

A ball screw is a high-precision mechanical component that converts rotational motion into linear motion with minimal friction. It uses a screw-driven mechanism with ball bearings circulating inside a nut to reduce resistance and improve efficiency. Widely used in CNC machinery, robotics, and industrial automation, ball screws offer unmatched accuracy, load capacity, and operational longevity.

Different Types of Ball Screws

Ball screw manufacturers design various types to meet different application needs:

Standard Ball Screws – Versatile and widely used, offering high efficiency and load-bearing capabilities.

High-Load Ball Screws – Engineered for heavy-duty performance, ideal for presses, injection molding, and machine tools.

Miniature Ball Screws – Perfect for compact equipment, such as medical devices, laboratory automation, and precision instruments.

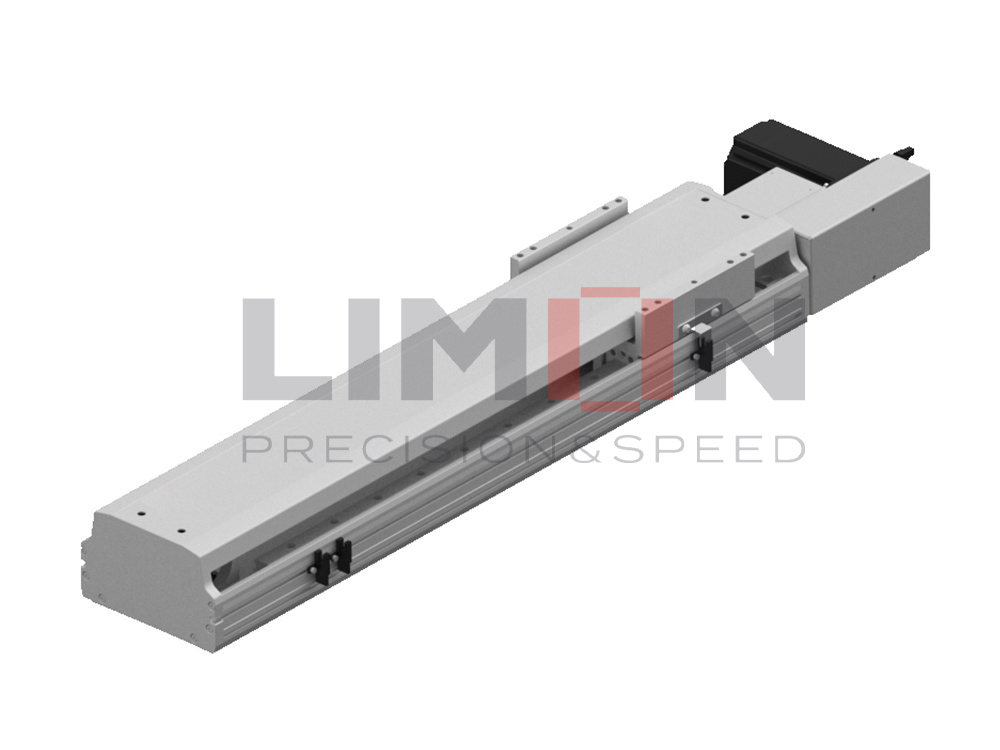

Compact Ball Screws – Offer space-saving designs with powerful output, frequently used in industrial automation systems.

Each of these ball screw designs serves unique demands—whether it’s micro-precision or industrial-strength load handling.

Who Makes the Best Ball Screws?

When it comes to top ball screw manufacturers, two names dominate the conversation:

NSK Ball Screws

Renowned for their cutting-edge engineering, NSK delivers world-class ball screw solutions tailored for high-speed, high-precision environments. Their screws feature excellent load capacity, low friction, and superior motion control, making them a go-to for robotics, semiconductor, and automotive industries.

THK Ball Screws

Another global giant, THK is known for producing high-performance ball screws used in automation, mechatronics, and precision tooling. Their products exhibit exceptional durability, tight tolerances, and a commitment to innovation in motion control.

Why Are Ball Screws So Expensive?

The cost of a ball screw reflects its precision, engineering complexity, and material quality. Here’s why:

Tight tolerances and complex threading require advanced machining.

Use of high-grade hardened steel and precision ball bearings.

Rigorous quality control, including testing for backlash, load limits, and smoothness.

Longevity and minimal maintenance requirements result in total cost-efficiency over time.

What Is Ball Screw NSK?

NSK ball screws are designed for optimal accuracy, load handling, and motion efficiency. These components are engineered for:

High-speed, low-friction operation.

Extended service life in tough conditions.

Seamless integration into automation, aerospace, and manufacturing systems.

Their extensive product range positions NSK as a leading ball screw manufacturer trusted across critical industries.

How Many Types of Ball Screws Are There?

In total, ball screw manufacturers produce several core variants:

Standard

Miniature

Compact

High-load

Plus specialty features like:

Preloaded ball screws (for anti-backlash)

Self-lubricating models (for maintenance-free use)

These variations are tailored for specific performance demands, environmental conditions, and spatial limitations.

What Is the Disadvantage of a Ball Screw?

Even the best ball screw manufacturers face these engineering challenges:

Regular maintenance is necessary to prevent wear and contamination.

Susceptible to backlash if improperly configured.

Sensitive to temperature fluctuations, which may affect accuracy.

Not always ideal for extremely dynamic load conditions.

Despite these concerns, the advantages—precision, efficiency, and durability—far outweigh the drawbacks when properly selected and maintained.

How Efficient Are NSK Ball Screws?

NSK ball screws are engineered for industry-leading efficiency:

Friction levels as low as 0.003–0.01, far outperforming lead screws.

Superior motion stability in high-speed environments.

Enhanced energy efficiency for automation lines and machinery.

Proven reliability in high-demand applications, from semiconductor fabrication to robotic assembly.

What Are the Grades of Ball Screws?

Ball screw grades define their accuracy class, a vital selection factor in engineering:

C5 – High-precision, used in automated inspection and precision tools.

C7 – Most common, perfect for general automation and machine tools.

C10 – Lower precision, suitable for non-critical systems.

Summary

Choosing the right ball screw manufacturer is about balancing performance, price, and application needs. Industry leaders like NSK and THK continue to raise the standard with high-precision, long-lasting ball screw systems tailored for today’s most demanding automation challenges.

Whether you’re sourcing for a robotic arm, semiconductor platform, or industrial CNC, investing in premium ball screws ensures long-term reliability and optimal performance.