Ball screws are the unsung heroes in modern automation. From electric drive systems to high-precision robotics, these components enable seamless conversion of rotary motion into linear motion with minimal friction and maximum efficiency. Here’s how they power the technologies that move our industries.

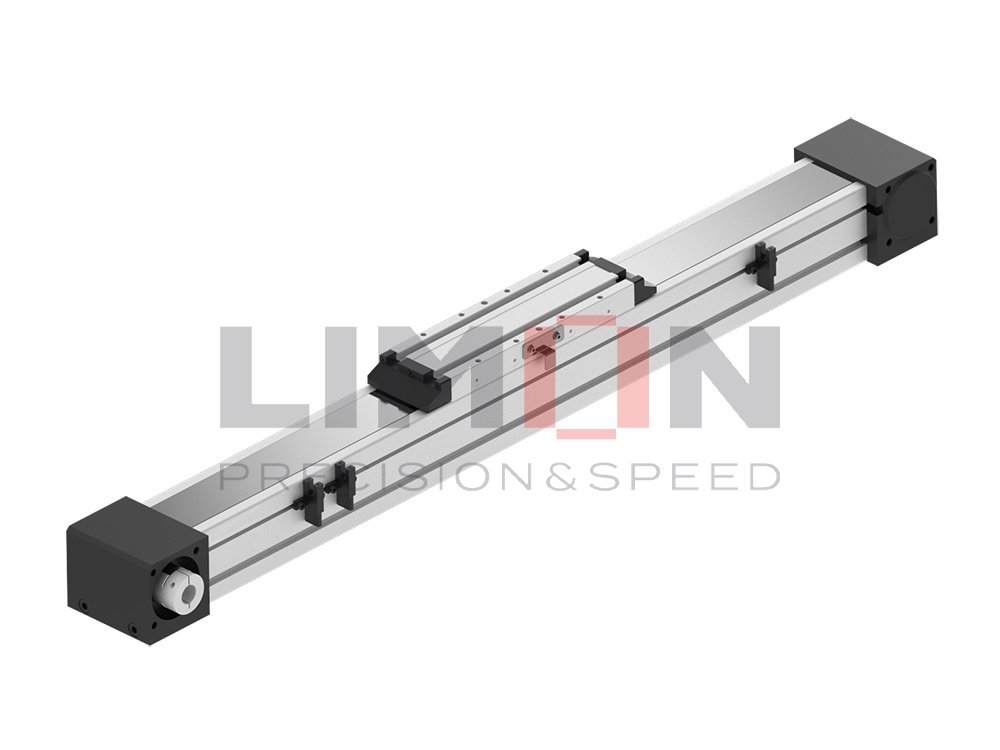

High-Efficiency Linear Motion in Electric Drive Systems

In electric drive systems, ball screws serve as critical components in translating motor-generated rotation into precise linear actuation. Their high mechanical efficiency—typically above 90%—makes them ideal for energy-conscious applications like electric power steering (EPS) in electric vehicles (EVs).

Ball screws reduce energy loss and ensure consistent performance in systems like:

Steering actuators

Power seat adjustments

Battery module handling systems

Their low friction not only minimizes heat and wear but also extends system lifespan—an essential factor in automotive electric drive designs.

Precision and Reliability in Robotics

When it comes to robotic systems, accuracy is everything. Ball screws in robotics enable repeatable, backlash-free movements in robotic arms, gantry systems, and pick-and-place machines.

Applications include:

Industrial robots on automated production lines

Medical robots for minimally invasive surgery

3D printing and additive manufacturing systems

Thanks to their ability to handle heavy axial loads while maintaining micron-level positioning accuracy, ball screws are preferred over belt drives and pneumatic actuators in precision-dependent environments.

Load Handling and Smooth Operation for Heavy-Duty Robotics

One of the greatest strengths of ball screws is their ability to combine load-bearing capacity with smooth linear motion. In robotic arms that manipulate large or intricate objects, this balance is key.

For example, in collaborative robots (cobots) that work alongside humans, ball screws enable force feedback, smooth trajectory control, and safe deceleration. Their performance is also consistent in high-duty-cycle environments like:

Automated warehousing

Heavy assembly lines

Material handling systems

Speed, Accuracy, and Scalability in Advanced Robotics

Modern robotics demand more than just strength—they require speed, precision, and adaptability. Ball screws offer a superior speed-to-accuracy ratio, ideal for rapid positioning without compromising accuracy.

Whether it’s a high-speed vision-guided robotic system or a surgical robot performing micro-incisions, the zero-lash, repeatable motion delivered by ball screws is mission-critical. Their modularity also supports scalable applications, from desktop robot platforms to large-scale gantry systems.

Summary: Why Ball Screws Are Essential in Electric Motion Control

In both electric drive systems and robotics, ball screws stand out for their:

Exceptional efficiency and energy savings

High precision with minimal backlash

Durability under continuous operation

Ability to handle heavy loads and high-speed cycles

Whether you’re developing EV platforms or next-gen robotic automation, integrating ball screw linear actuators ensures performance, reliability, and long-term value.