In industrial automation, inaccurate positioning and unstable movement lead to production inefficiencies and increased costs. These issues result in product defects and wasted resources. Ball screw driven positioning stages provide a precise, durable, and efficient solution to ensure optimal motion control.

Ball screw driven positioning stages utilize a ball screw mechanism to convert rotational motion into linear motion with high precision, efficiency, and stability, making them ideal for automation, robotics, and CNC applications.

Understanding the working principles, benefits, and movement characteristics of ball screw driven positioning stages can help optimize industrial processes. Read on for a detailed breakdown.

What Is a Ball Screw Drive?

A ball screw drive is a mechanical device that converts rotational motion into linear motion with minimal friction. It consists of a screw shaft and a ball nut with recirculating ball bearings, which reduce friction and enhance efficiency. Unlike lead screws, which experience high wear and require frequent lubrication, ball screw drives ensure smoother operation, higher accuracy, and greater load-bearing capacity.

Key characteristics of a ball screw drive include:

- High Efficiency: The rolling contact of the ball bearings minimizes energy loss.

- Accuracy: Offers precise movement control essential for automation.

- Durability: With proper lubrication, ball screws last significantly longer than lead screws.

- Low Backlash: Reduced play ensures consistent positioning.

Due to these advantages, ball screw drives are widely used in CNC machinery, semiconductor manufacturing, and precision positioning applications.

How Ball Screw Driven Stages Work

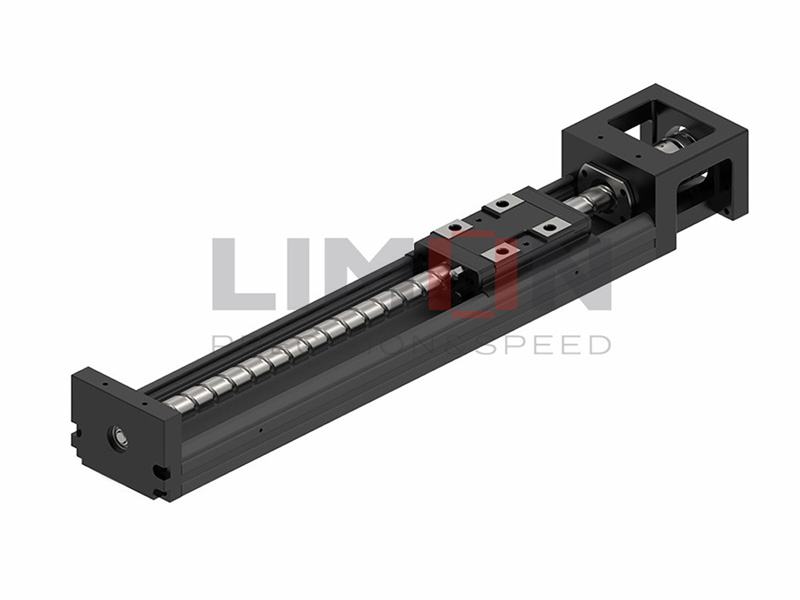

Ball screw driven positioning stages function by using a motor-driven ball screw system to create controlled linear movement. The system typically includes:

- Ball Screw & Nut – Converts rotational motion into linear motion with minimal resistance.

- Guide Rails – Ensures stable, smooth movement along a fixed path.

- Motor (Stepper/Servo) – Powers the screw drive for precise positioning.

- Frame & Housing – Provides structural integrity and vibration resistance.

- Feedback Systems – Encoders enhance accuracy by monitoring position changes.

By synchronizing these components, ball screw driven positioning stages deliver reliable, repeatable, and highly accurate movement, making them crucial in automation and manufacturing applications.

Product Benefits and Highlights

Ball screw driven positioning stages offer multiple benefits that enhance motion control in various industries:

- Exceptional Accuracy – Reduces errors and ensures micron-level precision.

- High Load Capacity – Handles heavier loads without compromising performance.

- Smooth & Consistent Movement – Reduces vibration for steady motion.

- Long Lifespan – Requires minimal maintenance with proper lubrication.

- Low Friction & High Efficiency – Maximizes energy savings and performance.

These benefits make ball screw driven positioning stages the preferred choice for high-precision applications in industrial automation, optics, and semiconductor industries.

What Is the Movement of the Ball Screw?

Ball screw movement is characterized by high-precision linear motion achieved through the recirculation of ball bearings within the nut assembly. This mechanism ensures:

- Linear Motion with Minimal Resistance: The rolling contact reduces friction significantly compared to conventional screw drives.

- Bidirectional Control: Ball screw driven systems enable precise forward and backward movements.

- Consistent Speed & Force: Ensures uniform performance, even under varying loads.

- Minimal Wear & Tear: The efficient design extends the system’s operational lifespan.

These attributes make ball screw driven systems a superior choice for applications requiring high-speed, accurate linear positioning.

Summary

Ball screw driven positioning stages offer precision, efficiency, and durability in industrial applications. Their low friction, high load capacity, and accurate motion control make them essential for advanced automation and manufacturing solutions.For further questions please contact [email protected]