Unreliable positioning and motion control cause design failures, production delays, and system inefficiencies. A stepper motor solves these issues with precise, repeatable movement ideal for automation. Let’s explore how.

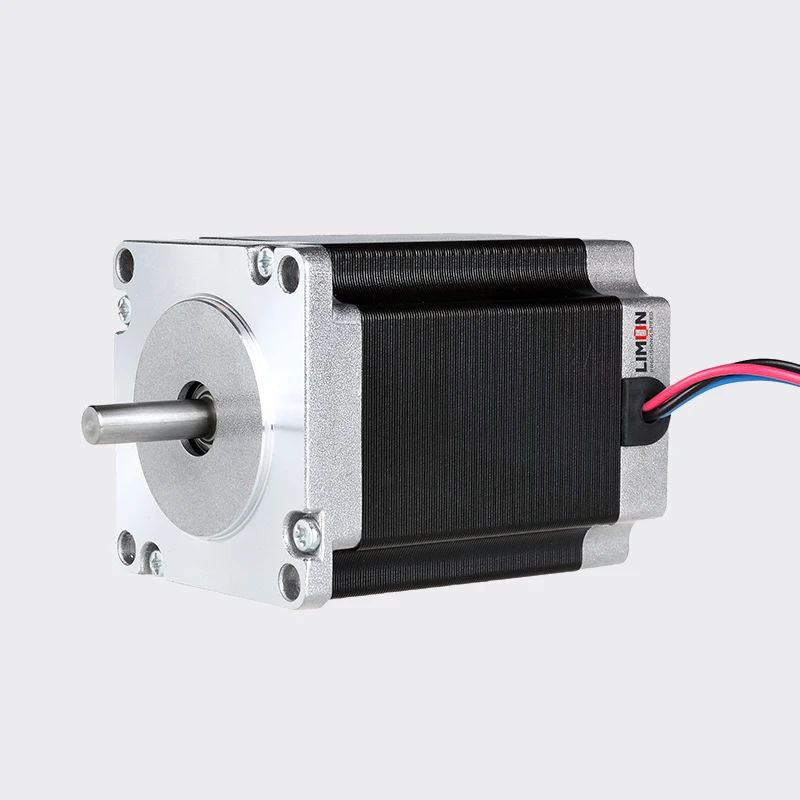

A stepper motor is a brushless, synchronous electric motor that moves in discrete steps, offering accurate, open-loop control of position, speed, and torque in automation systems.

Keep reading to understand how stepper motors operate and where they excel.

What is a Stepper Motor?

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements. Unlike conventional motors that rotate continuously, a stepper motor divides a full rotation into equal steps, enabling precise control of position without the need for feedback systems.

Stepper motors typically have multiple coils organized in phases. These coils are energized in a specific sequence, causing the rotor to move step by step. The number of steps per revolution depends on the motor’s design—commonly 200 steps per rotation (1.8° per step) for standard motors.

Key characteristics of a stepper motor include:

Precise positioning without feedback

Repeatable and predictable motion

High torque at low speeds

Digital control compatibility (ideal for microcontrollers and PLCs)

These features make stepper motors particularly useful in applications where accuracy, reliability, and low-cost control are required.

How Do Stepper Motors Work?

A stepper motor works by energizing its stator windings in a specific sequence, creating a rotating magnetic field that causes the rotor to follow in discrete steps. The stepwise nature of its rotation distinguishes it from traditional DC motors.

Here’s a breakdown of the operating principle:

Stator Coils: Arranged in phases (usually 2, 4, or 5), the stator is powered in a sequence that rotates the magnetic field.

Rotor: Made of permanent magnets or soft magnetic material, the rotor aligns with the magnetic field as it shifts.

Stepping Sequence: The controller sends pulses that determine which coil is energized next. Each pulse results in one step movement.

Microstepping: By modulating current between phases, the motor can achieve finer steps—improving smoothness and resolution.

Control methods include:

Full-step driving: The motor moves one full step at a time.

Half-step driving: Alternates between full and half steps for smoother motion.

Microstepping: Splits each step into smaller parts (up to 256 microsteps) using PWM current control.

The speed of the motor is determined by the frequency of the input pulses. Torque characteristics vary with speed and input current, and proper driver matching is essential for optimal performance.

Types of Stepper Motor

Several types of stepper motors are available, each suited for specific operational needs. Understanding their differences helps in selecting the right motor for your application.

1. Permanent Magnet (PM) Stepper Motors

These use a permanent magnet in the rotor. Known for low cost and high torque at low speeds, they are suitable for consumer electronics and basic robotics.

Pros:

Simple construction

Good holding torque

Cons:Limited resolution

Lower speed capabilities

2. Variable Reluctance (VR) Stepper Motors

VR motors have a rotor made of soft iron and operate on the principle of minimum reluctance. They offer high stepping rates but lower torque.

Pros:

High stepping speed

No detent torque

Cons:Lower torque

Less common in modern systems

3. Hybrid Stepper Motors

These combine PM and VR designs, offering high precision, better torque, and finer step angles (typically 1.8° or 0.9° per step). They are the most widely used in industrial applications.

Pros:

High accuracy

Good speed-torque characteristics

Supports microstepping

Cons:Slightly more expensive

4. Closed-Loop Stepper Motors

Equipped with encoders, these motors combine open-loop simplicity with feedback-driven performance, correcting missed steps in real time.

Pros:

No step loss

Efficient power usage

Cons:Higher system cost

Requires additional controller logic

Selecting the right stepper motor type involves balancing precision, torque, speed, and cost based on your system’s requirements.

What is a Stepper Motor Used For?

Stepper motors are used in applications that require accurate, repeatable, and controllable positioning or rotation without complex feedback systems. Their open-loop control and compatibility with digital electronics make them ideal for a wide range of industries.

Common Applications:

1. 3D Printers

Stepper motors control the movement of the print head and the build platform. Their precision ensures layer alignment and smooth surface finishes.

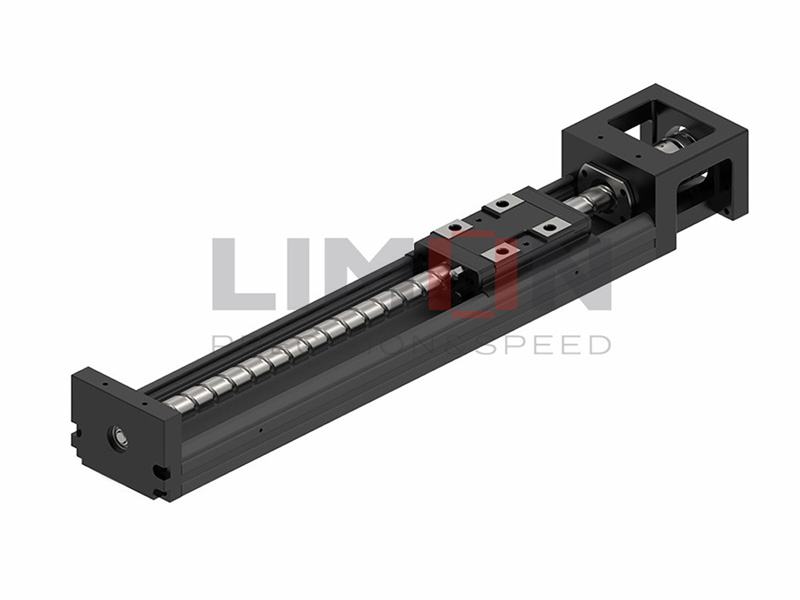

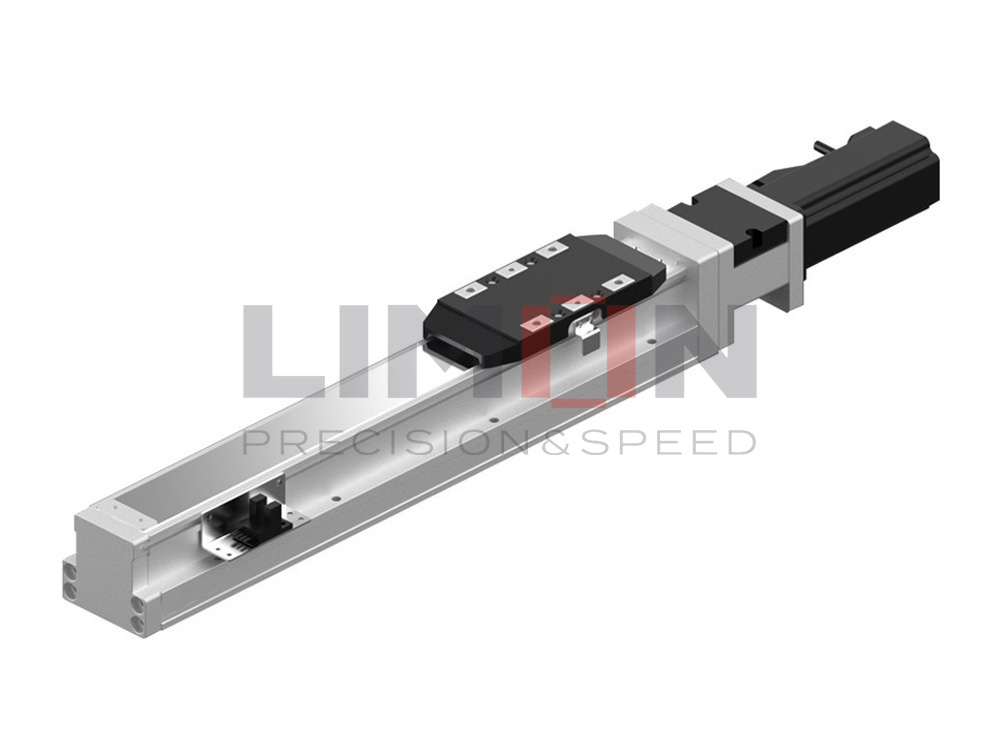

2. CNC Machines

Used to drive the X, Y, and Z axes, stepper motors offer repeatability and cost-efficiency for routing, engraving, and milling tasks.

3. Camera Platforms

Pan-tilt systems and focus mechanisms often use stepper motors for controlled motion without overshooting.

4. Robotics

From joint actuators to conveyor positioning, stepper motors offer predictable movement that can be easily programmed into autonomous routines.

5. Medical Devices

Used in pumps, imaging systems, and lab automation for dosing and scanning applications requiring high control precision.

6. Automated Manufacturing

Stepper motors drive pick-and-place machines, label applicators, and packaging systems where exact motion is essential.

Stepper motors are especially popular in systems where closed-loop feedback is unnecessary or too costly, and where motion must be tightly synchronized with digital control logic.

Summary

Stepper motors deliver precise, repeatable motion ideal for automation, robotics, and digital control—powering reliable systems across industries.For further questions please contact [email protected]

2.jpg)