Slow positioning, high noise, and short lifespan plague outdated motion systems—hurting productivity. Toothed belt-driven linear axes solve this with speed, silence, and reliability. Discover how.

Linear axes with toothed belt drive provide high-speed, precise, and low-maintenance motion control. These systems are ideal for automation tasks requiring long strokes, consistent accuracy, and smooth operation.

Explore their design, benefits, and motor compatibility below.

Advantages of Toothed Belt Axles

Toothed belt axles offer several significant advantages for modern industrial applications, especially where speed, stroke length, and cost-efficiency are key concerns.

1. High Speed and Acceleration

Unlike screw-driven systems, toothed belt axes can achieve much higher speeds—often exceeding 5 m/s—and offer quick acceleration without compromising stability. This makes them ideal for pick-and-place systems, packaging lines, and fast transport tasks.

2. Long Stroke Capability

Linear axes with toothed belt drive support extended travel lengths (sometimes over 6 meters) without losing accuracy. Unlike ball screw setups, which are limited by screw deflection and whip, toothed belt axes are much more scalable in this regard.

3. Low Maintenance and Clean Operation

Thanks to fewer moving parts and no recirculating ball bearings, these systems require minimal maintenance. Belts are self-lubricating and run clean, making them suitable for industries such as medical, food processing, and semiconductors.

4. High Repeatability and Accuracy

Despite not being contact-based like screws, high-quality toothed belts combined with linear guideways can still achieve repeatability within ±0.05 mm—ideal for most automation tasks.

5. Quiet and Smooth Running

The toothed belt mechanism eliminates metallic friction, producing less vibration and significantly lower noise levels compared to chain or gear-driven alternatives.

6. Cost-Effective

With fewer components and simpler assembly, linear axes with toothed belts offer a lower overall cost, both in terms of initial investment and maintenance over time.

In summary, toothed belt axles balance performance, affordability, and flexibility—ideal for a broad spectrum of automation challenges.

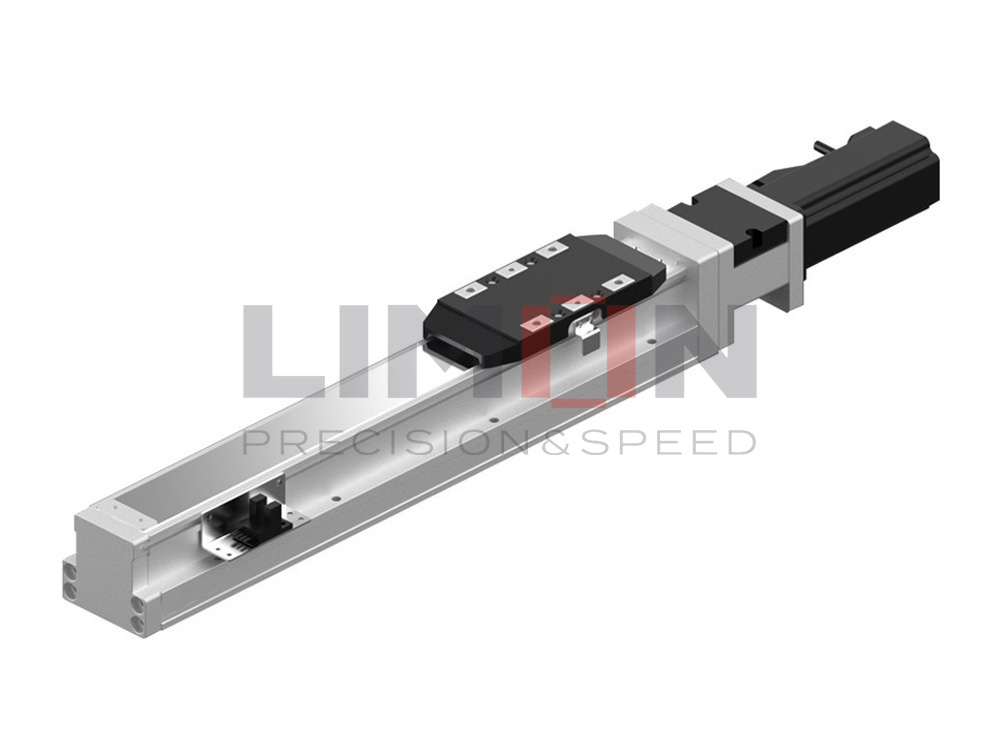

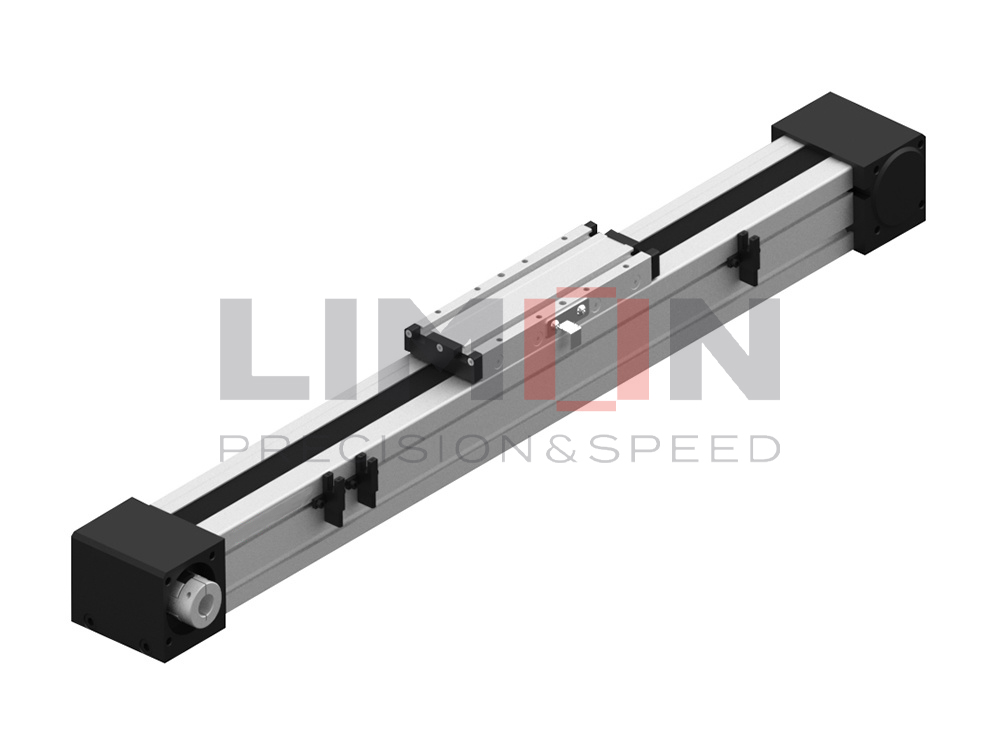

Structure of a Toothed Belt Axis

Understanding the anatomy of a toothed belt axis is essential for effective system integration. The design integrates multiple elements to enable precise and reliable linear motion.

1. Toothed Belt

The core transmission component is the belt, typically made from polyurethane reinforced with high-tensile fibers such as steel or Kevlar. Its teeth engage precisely with the drive pulley to eliminate slippage and ensure synchronized motion.

2. Pulleys and Shafts

One end of the axis features a drive pulley connected to the motor shaft, while the opposite end holds an idler pulley to maintain belt tension. Both pulleys are supported by precision bearings to reduce rotational resistance.

3. Linear Guideways

Mounted parallel to the belt, linear guideways ensure the carriage moves smoothly and remains aligned. These guides offer high rigidity and low friction, providing accuracy and support under load.

4. Carriage/Slider Platform

Attached to the moving part of the belt, the carriage carries tools or payloads. Its design varies depending on load requirements and may integrate tapped holes, sensors, or protective covers.

5. Motor Mount & Coupling

The motor is connected to the drive pulley via a flange or integrated mount. The choice between stepper and servo motors depends on speed, torque, and precision needs.

6. Base Profile and Housing

The aluminum or steel profile provides structural support, ensuring rigidity and protecting internal components. Sealed and open frame options exist depending on environmental conditions.

This modular structure allows easy customization in stroke length, carriage size, and motor configuration to suit diverse industrial needs.

Application Examples with Toothed Belt Axles

Toothed belt-driven linear axes are used across a wide range of industries due to their flexibility, long-stroke capacity, and excellent cost-to-performance ratio.

1. Packaging Automation

Fast, repetitive movement in vertical and horizontal packaging systems benefits from the high speed and long reach of toothed belt axes. For example, cartoning machines, label applicators, and palletizers rely on them for positioning accuracy.

2. Electronics Assembly

In PCB and component assembly lines, linear axes help position soldering heads, conveyors, and cameras with precision. Their quiet operation and clean environment compatibility are especially useful.

3. Medical and Pharmaceutical Equipment

Applications such as diagnostic imaging, sample handling, and automated medicine dispensing benefit from the smooth, particle-free operation of toothed belt axes, especially in cleanroom settings.

4. Laser Engraving and Cutting

These machines require high-speed scanning and precise positioning, which toothed belt systems provide reliably. Lightweight carriages ensure swift acceleration and deceleration for sharp, detailed results.

5. 3D Printing and CNC Routing

Many mid- to large-format 3D printers and light-duty CNC routers employ toothed belt systems for their cost-effectiveness and ability to handle long print beds without vibration or backlash.

6. Photovoltaic and LCD Manufacturing

Long-stroke transport of delicate materials requires accurate, non-contact handling. Toothed belt axes provide consistent motion while reducing mechanical stress on sensitive components.

These examples demonstrate the wide applicability of toothed belt linear axes in sectors that value reliability, quietness, and cost efficiency.

Which Motors Can I Connect to the Toothed Belt Axes?

Toothed belt-driven linear axes are highly adaptable in terms of motor integration. Depending on application complexity, different types of motors can be connected:

1. Stepper Motors

Common in entry-level or budget-conscious systems, stepper motors offer reliable motion with simple control schemes. They work well in applications where high precision and torque are not critical, such as light-duty pick-and-place machines or labeling stations.

2. Servo Motors

For applications demanding high accuracy, dynamic performance, or load variation, servo motors are the preferred choice. They enable closed-loop control, offer high torque at speed, and support features like encoder feedback and auto-tuning.

3. Integrated Motor-Drive Units

Some compact systems benefit from integrated motors that combine the controller, driver, and motor in a single unit. These simplify wiring, reduce panel space, and lower overall system costs.

4. Gearbox Integration

In cases requiring more torque or reduced speed, planetary or spur gearboxes can be fitted between the motor and pulley. This is common in heavy payload applications or when motors must run at constant speeds.

5. Multi-Axis Configurations

Toothed belt axes can also be combined in gantry setups (X-Y or X-Y-Z) powered by synchronized motor drives. This setup is widely used in CNC routers, plasma cutters, and automated testing systems.

When selecting a motor for your toothed belt axis, consider the required speed, acceleration, load, positional accuracy, and available control hardware.

Summary

Toothed belt-driven linear axes offer fast, reliable, and scalable motion solutions—perfect for high-speed automation and long-travel industrial applications.For further questions please contact [email protected]