Industrial automation demands high-speed, precise linear motion. Inefficient drive systems lead to costly downtimes and reduced productivity. Toothed belt drive linear axes offer a reliable, efficient solution, ensuring smooth, high-speed motion with minimal maintenance.

A toothed belt drive is a high-performance motion system that combines speed, precision, and durability. Toothed belt axles are widely used in automation, CNC machines, and material handling due to their low maintenance, lightweight design, and excellent repeatability. Their ability to provide smooth, backlash-free movement makes them an ideal choice for high-speed applications.

Understanding toothed belt drive systems ensures optimal selection and performance for various industrial applications.

What is a Toothed Belt?

A toothed belt is a type of belt with teeth on its inner surface that mesh with corresponding grooves on a pulley. Unlike smooth belts, it prevents slippage, ensuring synchronized motion. These belts are commonly made from reinforced rubber or polyurethane, providing high durability and flexibility.

The design of a toothed belt enables efficient power transmission while maintaining precise movement. Industries such as robotics, packaging, and automation rely on toothed belts for applications requiring repeatable and accurate linear motion. Their ability to operate at high speeds with minimal noise and vibration makes them ideal for modern automated systems.

Advantages of Toothed Belt Axles

Toothed belt axles offer several benefits that make them preferable over traditional motion systems:

- High Speed & Efficiency – Capable of rapid acceleration and deceleration without losing accuracy.

- Low Maintenance – No need for lubrication or frequent adjustments.

- Durability – Resistant to wear, ensuring long operational life.

- Low Noise – Operates smoothly with minimal vibration.

- Backlash-Free Movement – Ensures precision in positioning and motion control.

- Compact Design – Lightweight and space-saving, making it ideal for constrained environments.

These advantages make them suitable for applications that demand consistent and reliable linear motion.

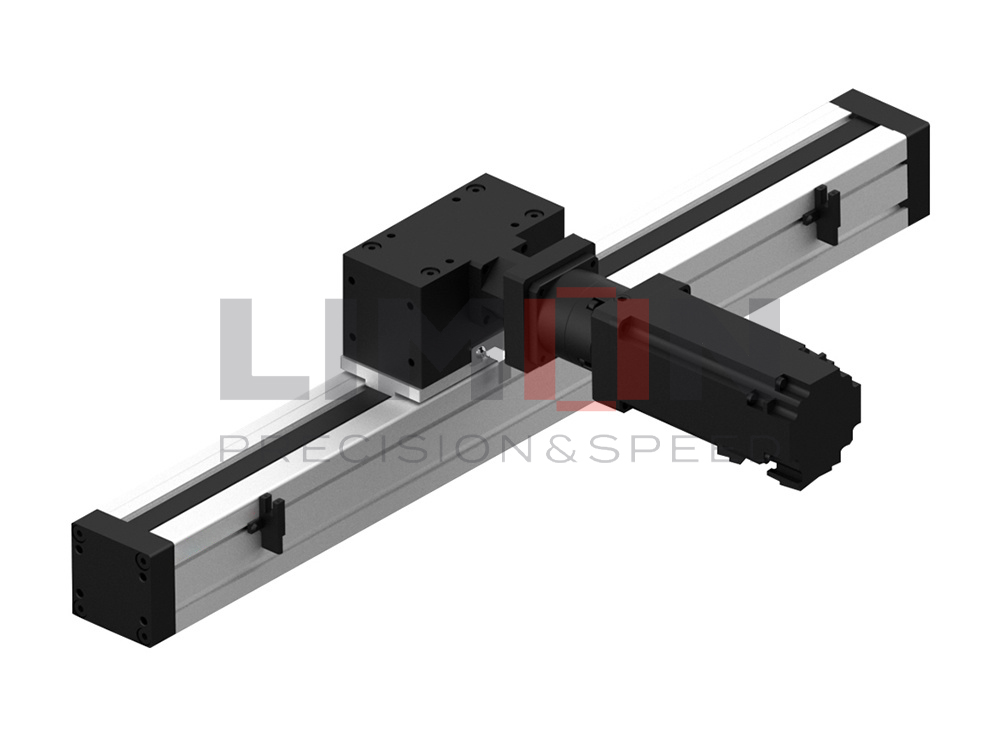

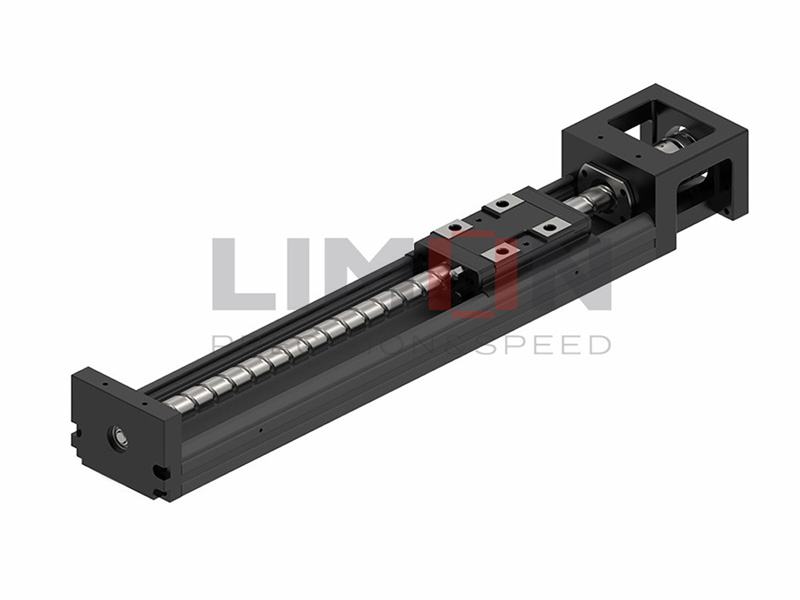

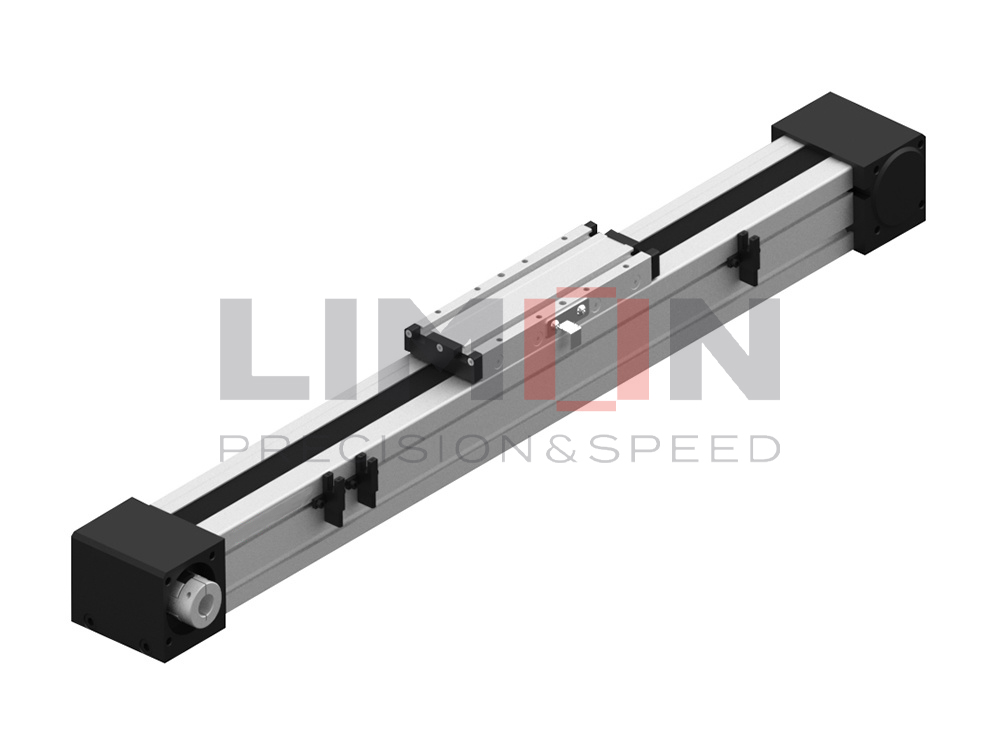

Structure of a Toothed Belt Axis

A toothed belt axis consists of several key components:

- Toothed Belt – Provides power transmission with a secure grip on the pulleys.

- Guides and Bearings – Maintain smooth and stable motion along the axis.

- Pulley System – Converts rotary motion into linear movement.

- Frame – Supports the entire structure, ensuring rigidity and precision.

- Tensioning Mechanism – Maintains proper belt tension to prevent slippage and wear.

The synergy between these components ensures efficiency, durability, and high-speed performance in automated systems.

Application Examples with Toothed Belt Axles

Toothed belt axles are widely used across various industries, including:

- Robotics – Ensuring precise linear motion for robotic arms.

- CNC Machinery – Providing accurate and rapid positioning in milling and cutting applications.

- Material Handling – Enabling smooth movement in conveyor systems.

- Packaging Industry – Ensuring synchronized motion for high-speed packaging machines.

- Medical Equipment – Delivering precision in laboratory automation and diagnostic devices.

These applications highlight their versatility and importance in modern industrial automation.

How Long Does a Toothed Belt Last?

The lifespan of a toothed belt depends on various factors:

- Material Quality – High-grade polyurethane or rubber belts last longer.

- Operating Conditions – Excessive loads or harsh environments reduce lifespan.

- Proper Tensioning – Prevents premature wear and improves efficiency.

- Maintenance & Inspection – Regular checks extend service life.

On average, toothed belts can last between 10,000 and 20,000 operating hours, depending on usage and environmental conditions.

Conclusion

Toothed belt axles offer a powerful combination of speed, precision, and reliability, making them indispensable in modern automation systems.For further questions please contact [email protected]