A: We pay great attention with the quality of our products and we have many quality certificates: ISO9001, ISO14001, CE European Union certification certificate, ROHS certificate etc.

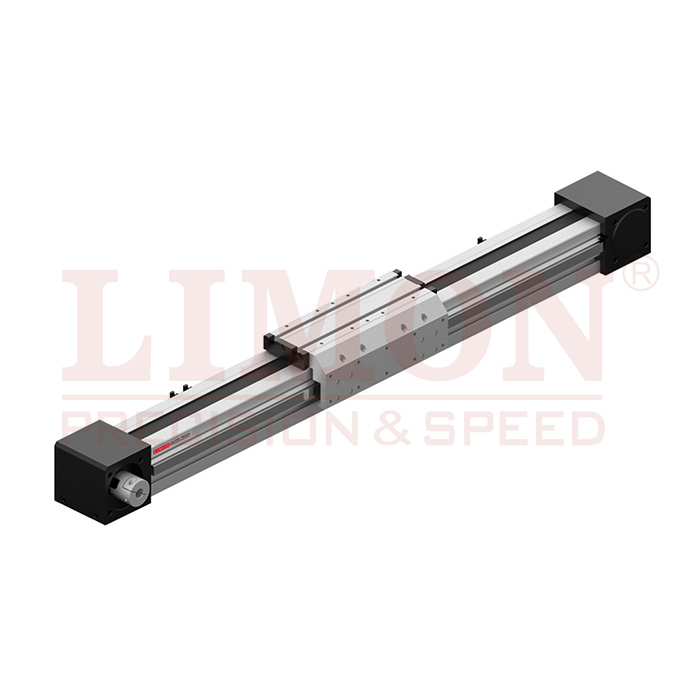

Belt Driven Linear Actuator – H Series

Belt Driven Linear Actuator

H Series

Open type

Classification: Open type

Drive type: Belt drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Heavy load capacity: Under the same working conditions, the load is nearly 2 times larger than that of the I series

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

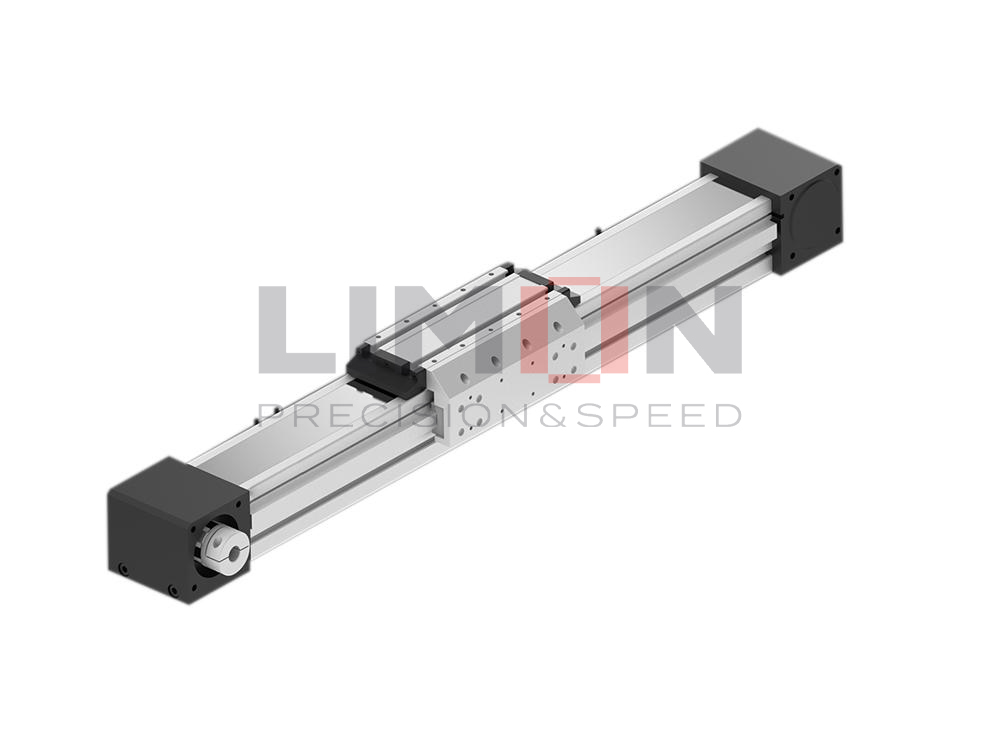

Close type

Classification: Close type

Drive type: Belt drive

Sealed type: Clean room environment, fully enclosed

Repetitive accuracy: ±0.05mm

Heavy load capacity: Under the same working conditions, the load is nearly 2 times larger than that of the I series.

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

Close type

Repetitive accuracy: ±0.05mm

Motor Fixed,not increase mobile terminal load

Good dynamic performance

Standard Rail

| HTZ80 | |||

| Technical Parameters | Repetitive Accuracy (mm) | ±0.05 | |

| Pulley Lead(mm) | 210 | ||

| Belt Type | 5M-50 | ||

| Maximum Speed (mm/s) | 2000 | ||

| Maximum Payload | Vertical(kg) | 30 | |

| Max.No-load Driving Torque(N·m) | 0.9 | ||

| Max.Driving Torque(N·m) | 49.8 | ||

| Basic Specification | Stroke(mm) | 1-1500 | |

| AC Servo Motor Output (W) | 400/750 | ||

| Linear Guide | 15#×2PCS | ||

| Max Outline of Main Engine’s Cross Section (mm) | 94×190 | ||

| Home Sensor | PM-Y45(NPN) | ||

Description

BELT DRIVEN TYPE

Close type: HTC80/100 (Long carriage available)

Open type: HTO60/80/100 (Long carriage available,except HTO60)

- The integrated design for pulley and coupling could keep the stability and save space

- This design can shorten the length of motor lateral installation, save the machine space

- It is very flexible, the motor mount could change to each side according to customer’s different design.

- We put the external oil holes on the block to avoid the disassembling,when the end user adding the grease.

Applicable Industrial: LCD panel manufacturing, Photovoltaic industry, white goods production line, lithium battery manufacturing, automation industrial

This series is uniaxial modules. While providing uniaxial modules, LIMON can also provide multi-axis combined projects, including necessary connecting parts, motor drive, reducer, drag chain belt, etc. Besides, our technicians also participates in customer projects, calculates design strength, and provides customers with a complete set of solutions.

Frequently Asked Questions

A: Yes, sample is available. If you are interested, you can contact us by e-mail ([email protected]) to get more photos and information.

A: Normal order delivery of linear motion products is generally controlled within 1-2 months.

Normal order delivery for linear unit and higher precision products is generally controlled within 7-15 working days.

A: Our cooperating transportation companies include DHL, TNT, UPS, etc. Sea transportation, air transportation and express delivery are all available. If you have a specific carrier, please let us know when you place the order.

A: You can contact us by e-mail ([email protected] ) and we will recommend the most suitable project according to your requirements.

A: T/T in advance.

A: LIMON agent in Asia: Singapore, Japan, India

LIMON agent in Europe: Hungary, Turkey, Israel

LIMON agent in South America: Brazil

A: LIMON do quite well in Europe, Asia and South America, also China is a potential market for us. Now LIMON’s distributors have covered more than 32 country and regions.

A: We are really looking forward to having you as a solid partner of LIMON. Please contact us by e-mail ([email protected] ) , we can start talk and get to know more about each other.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.