When you’re designing for precision linear motion, understanding the role and maintenance of linear bearings is crucial. Let’s address some of the most common technical questions related to linear bushings and linear motion systems.

Can Linear Bushings Replace Rolling Bearings?

Not typically—because linear bearings and rolling bearings are designed for entirely different types of motion.

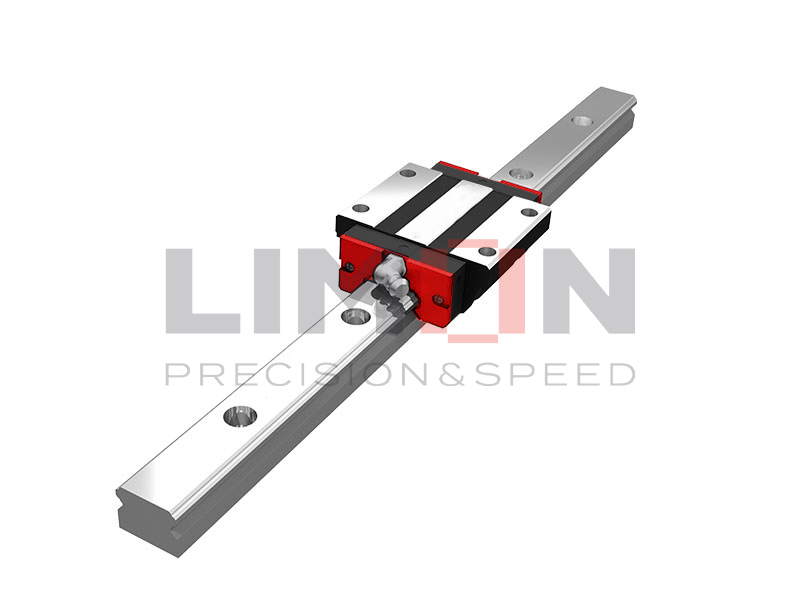

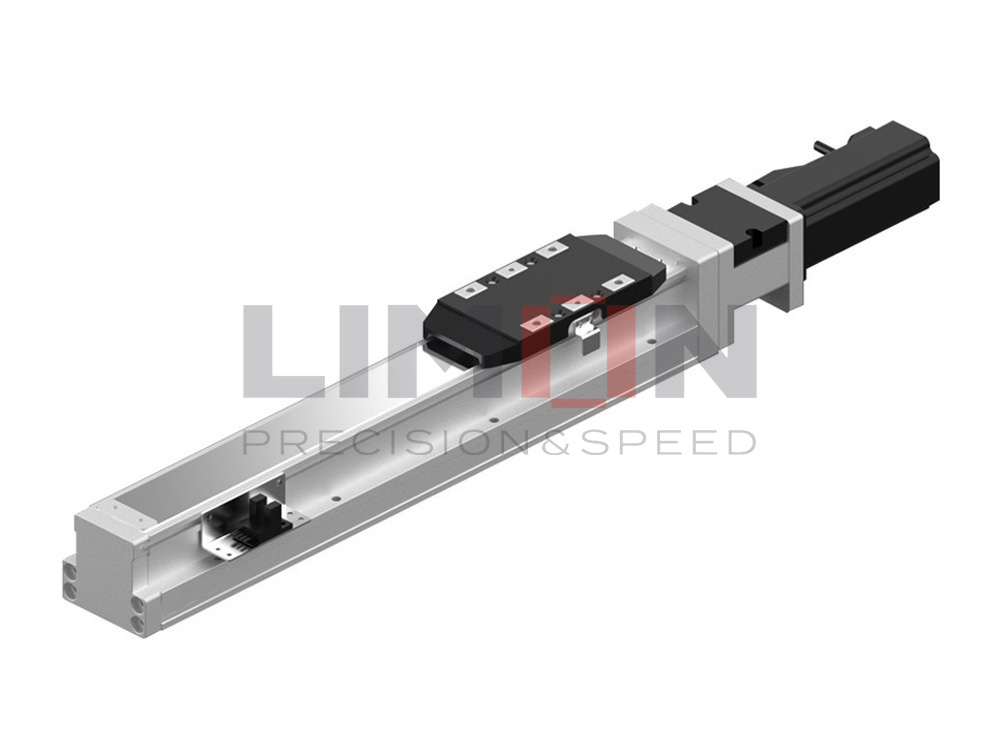

Linear bearings provide smooth motion in a straight line, commonly used in CNC machines, 3D printers, and industrial automation systems.

Rolling bearings (such as ball or roller bearings) are built to support rotational motion, ideal for shafts, pulleys, and spinning components.

How to Adjust the Clearance of Linear Bearings?

Clearance (or preload) in linear bearing systems directly affects their performance, smoothness, and precision. Here’s how to adjust it depending on the bearing type:

1. Adjustable Linear Bearings

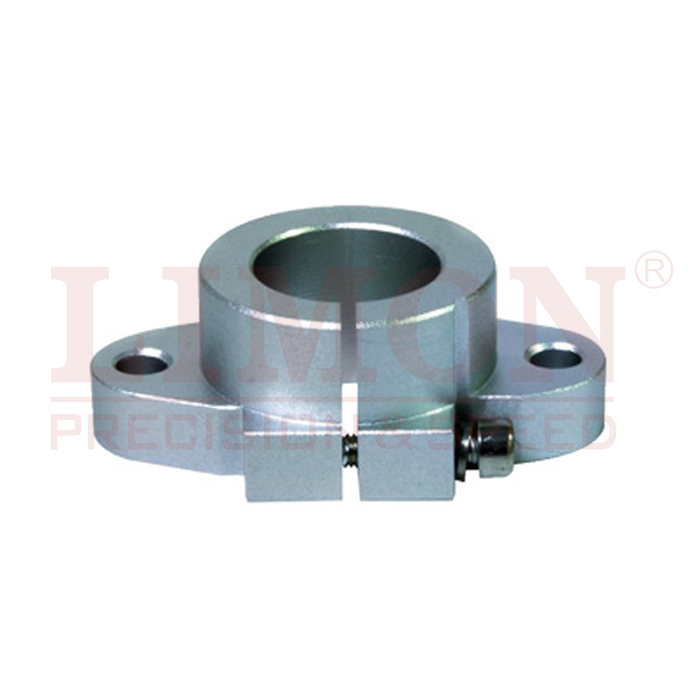

Some linear bushings, like pillow block-style linear bearings, have an external adjustment screw. Tighten it for reduced clearance or loosen it to increase play.

2. Precision Shimming

In linear guide rail systems, you can insert thin shims between the bearing block and the mounting surface to fine-tune the preload.

3. Eccentric Bushing Adjustment

Some linear bearings come with an eccentric bushing. Rotate it to subtly alter the gap and control the fit.

4. Factory-Set Preload

Certain profile rail linear bearings are sold with pre-determined preload levels. These cannot be adjusted post-installation, so it’s important to select the right preload option during procurement.

Can Linear Bearings Have Oil Holes?

Absolutely. Lubrication is essential for extending the life of linear motion components, and many linear bearings are designed with this in mind.

Pre-Engineered Oil Holes

Some linear bushings are manufactured with built-in oil ports or grease nipples to facilitate regular maintenance.

Custom Drilling

If your bearing doesn’t include oil holes, you may carefully drill custom lubrication holes—as long as it doesn’t interfere with the bearing raceway or compromise the housing structure.

Lubrication Fittings

For industrial automation applications, many linear bearings support automated lubrication systems, including grease lines and pressurized oil feed systems.

Summary

Linear bushings cannot replace rotational rolling bearings without a major application redesign.

Adjusting bearing clearance requires the right method—be it screws, shims, or eccentric bushings—based on your specific linear bearing type.

Proper lubrication access via oil holes or fittings is key to maximizing performance and longevity in linear motion systems.