Poor support in motion systems causes vibration, misalignment, and premature wear. A reliable ball screw support unit ensures precision, rigidity, and extended lifespan. Here’s what you need to know.

Ball screw support units are essential components that secure and stabilize ball screw assemblies, ensuring precise motion, reduced vibration, and long-term durability across demanding industrial applications.

Read on to explore structures, types, and design benefits.

What are the Components of a Ball Screw?

A ball screw is a mechanical linear actuator that translates rotational motion into linear motion using a threaded shaft and a ball nut with recirculating ball bearings. To function effectively, the ball screw system requires precise alignment and support—which is where the ball screw support unit comes into play.

The key components of a ball screw system include:

Screw Shaft: A long, threaded rod that provides the path for linear motion. Threads are either rolled or ground for specific applications.

Ball Nut: Encases the balls and rides along the screw shaft, transferring the rotary motion into linear movement.

Ball Bearings: Recirculating balls between the nut and screw shaft reduce friction and enable high-efficiency motion.

Support Units: Positioned at both ends of the screw, these units consist of preloaded bearings and housings that provide rigidity, axial support, and alignment.

Couplings & Motor Mounts: Used to connect the screw to a motor for actuation.

Without proper support units, the screw shaft may deflect under load, introducing backlash and reducing system accuracy. High-performance support units minimize this risk by offering secure end support and absorbing axial and radial forces.

Types of Ball Screw Support Units

Ball screw support units come in various types to match different mounting requirements, load conditions, and performance specifications. They are typically classified based on their location on the screw and the type of bearings used.

1. Fixed Support Units (e.g., BK, FK, EK, FK types)

These are mounted at the drive end of the screw. They incorporate two angular contact bearings with preloaded settings to provide both axial and radial support. These units are critical for applications that require high positioning accuracy and rigidity.

2. Floating or Simple Support Units (e.g., BF, EF, FF types)

Located at the opposite end of the fixed side, these support units typically use single radial bearings. Their primary purpose is to guide the screw while allowing for thermal expansion, preventing bending or stress buildup.

3. Compact and Flange Types

Some units are designed with a flange-style housing, enabling face-mounting to the machine frame. Compact units are ideal for applications with space constraints and lightweight designs.

4. Standardized Pre-machined Kits

Manufacturers like LIMON offer support units that match standard ball screw shaft end machining. These units ensure seamless integration, precision fit, and quick assembly.

Proper selection of support unit types ensures optimal performance, minimal backlash, and reduced mechanical wear in the ball screw system.

Ball Screw Support Structure and Features

The ball screw support unit is a compact assembly designed to house precision bearings within a rigid enclosure, providing structural support to the ball screw shaft.

Key structural features include:

Preloaded Angular Contact Bearings

The fixed-end support uses dual angular contact bearings that are factory preloaded to eliminate axial clearance. This enhances positioning precision and stiffness under load.High-Rigidity Housing

Support units are machined from steel or aluminum alloy to provide excellent rigidity. Surface treatments such as black oxide or anodizing help resist corrosion.Sealing and Greasing

High-quality seals protect the bearings from contaminants. Most support units are pre-greased and sealed for life, eliminating the need for routine maintenance.Positioning Accuracy

The support structure integrates dowel pin holes or machined base surfaces to ensure alignment with the ball screw shaft and linear axis system.Easy Installation Features

Support units are designed with pre-drilled mounting holes and standardized interfaces to align with machine frames. This simplifies assembly and reduces installation time.

These structural elements ensure smooth, accurate movement while supporting axial thrust and maintaining screw alignment—even in high-speed, high-load environments.

Uses the Optimal Bearing

The performance of a ball screw support unit heavily depends on the type and quality of bearing used. Optimal bearing selection directly impacts load handling, vibration resistance, and system life.

Angular Contact Ball Bearings (ACBB)

These are the most common bearings used in fixed-end support units. They are designed to support both radial and axial loads and are typically mounted in pairs with back-to-back or face-to-face configuration. Preloaded angular contact bearings eliminate backlash and increase rigidity.

Radial Ball Bearings

Used in floating or simple support units, these bearings support radial loads and allow axial movement to accommodate thermal expansion. Though less rigid than angular types, they serve a critical role in long-stroke systems.

Bearing Preload Options

Manufacturers like LIMON offer support units with factory-set preload. This minimizes assembly errors, ensures consistent stiffness, and improves dynamic response. High-precision applications often require C3 or C5 class bearings with matching ball screw grades.

Sealing and Lubrication

Bearings inside support units are sealed and filled with high-performance grease. This ensures smooth operation, extended life, and protection from contaminants—especially important in dusty or corrosive environments.

Choosing the optimal bearing configuration ensures high-speed stability, accurate motion control, and long-term reliability of the ball screw system.

Support Unit Shapes

Ball screw support units come in various shapes and configurations to meet the diverse needs of industrial environments. Understanding the differences helps in choosing the right form factor for machine design.

Flange Type

Flange-type units (e.g., FK, FF) feature a circular or rectangular flange that enables face mounting. These are common in machines with limited mounting depth or where alignment from the front is easier.

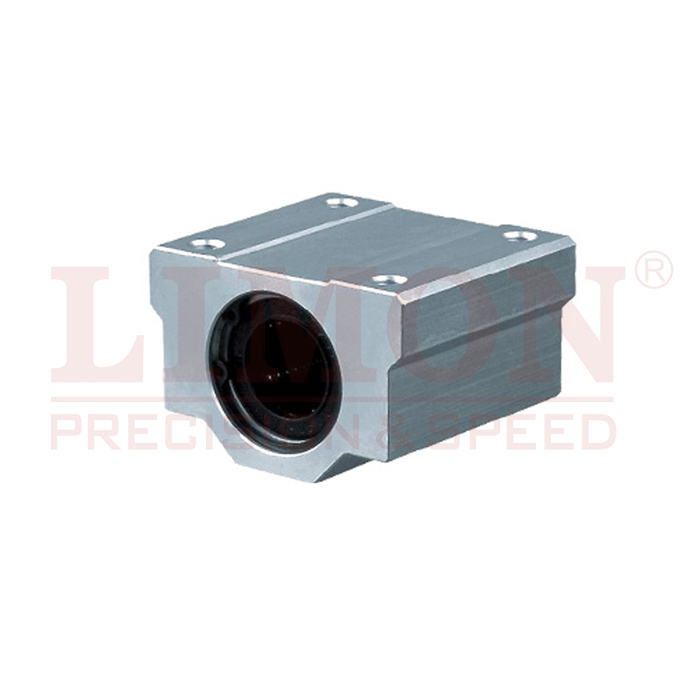

Block Type

Block-style supports (e.g., BK, BF, EK, EF) are designed as cubic blocks with mounting holes on the bottom. They offer excellent stability and are widely used in horizontal and vertical installations.

Compact Type

Some systems require compact support units that minimize space usage. These are ideal for lightweight applications or limited machine envelopes, without compromising rigidity.

Open-Type and Closed-Type Designs

Support units may feature an open housing to allow access for lubrication or adjustments, while closed designs provide better sealing and protection.

The choice of shape depends on:

Mounting method (horizontal, vertical, inverted)

Machine frame layout

Load direction and access for maintenance

Manufacturers typically provide detailed CAD files and specifications to ensure proper fit within the system design.

Compact and Easy Installation

Modern ball screw support units are engineered for quick installation and compact integration into machine systems. Time savings during assembly translate into lower operational costs and higher productivity.

Standardized Interfaces

Most support units are compatible with standard end machining specifications (e.g., bearing diameter, snap ring groove, shaft shoulder). This ensures plug-and-play compatibility with pre-machined ball screws.

Preassembled Designs

Manufacturers like LIMON supply preassembled units with preloaded, lubricated, and sealed bearings. This eliminates the need for manual bearing installation and adjustment.

Minimal Footprint

Compact body designs allow for tighter machine layouts, especially in multi-axis systems or portable automation solutions.

Quick Mounting

Support units include tapped holes or through-holes that align with mounting surfaces. Dowel pins or locating features ensure proper alignment with the linear motion axis.

Maintenance-Free Operation

Due to factory greasing and sealing, most support units require no periodic maintenance. This reduces downtime, improves MTBF (Mean Time Between Failures), and enhances machine reliability.

These features make support units easy to implement across applications, from CNC machining centers to semiconductor handling systems and 3D printing platforms.

Summary

Ball screw support units provide stability, precision, and simplified assembly—critical for maximizing performance and lifespan in linear motion systems.For further questions please contact [email protected]

_1.jpg)