Ball screw linear actuators are at the heart of precision automation. With their ability to convert rotary motion into highly accurate linear movement, they play a crucial role in industries demanding stability, repeatability, and load-bearing performance.

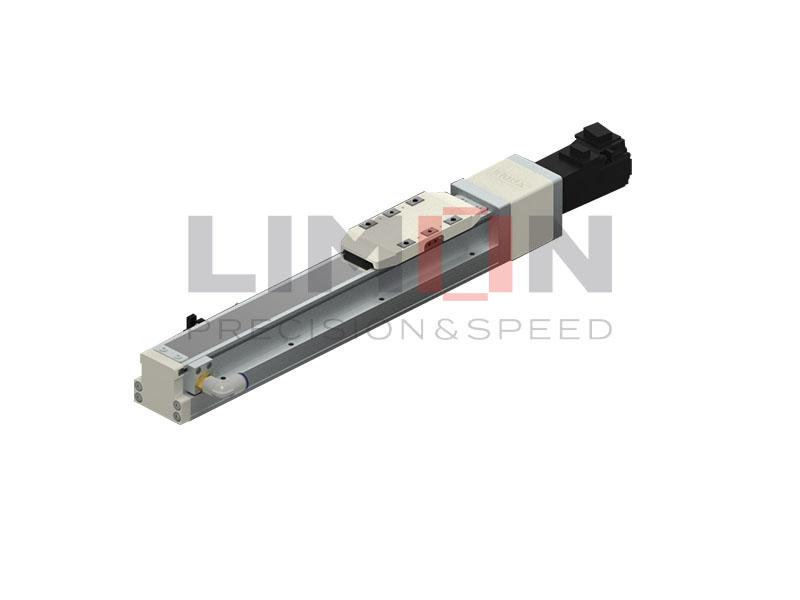

How Does a Ball Screw Linear Actuator Work?

A ball screw linear actuator operates by using a threaded shaft and a ball nut filled with recirculating ball bearings. This design drastically reduces friction, ensures smooth linear travel, and enhances positioning accuracy. The result? High-precision motion control with exceptional load capacity—ideal for mission-critical systems that can’t afford compromise.

CNC Machines: Precision Machining Starts Here

In CNC machining, ball screw linear actuators ensure micron-level positioning in milling, drilling, and grinding. Their minimal backlash and smooth actuation significantly improve cutting accuracy and reduce material waste—making them indispensable in high-precision manufacturing.

Semiconductor Industry: Cleanroom-Grade Precision

For semiconductor manufacturing, where particle control and micro-alignment are critical, ball screw linear actuators are used in wafer handling, optical inspection, and chip assembly. Their repeatable, frictionless motion ensures flawless component placement and inspection accuracy.

Medical Equipment: Smooth, Reliable Movement

In medical systems such as robotic surgery platforms, diagnostic imaging, and lab automation, ball screw actuators provide the delicate, smooth movement required for patient safety and procedural accuracy. Their stability supports applications like CT scanners, surgical robots, and automated blood analyzers.

Automation & Robotics: Precision Meets Speed

From pick-and-place robots to high-speed assembly, ball screw linear actuators deliver unmatched positioning precision and repeatability. Their robustness and consistent performance make them the go-to component in demanding industrial automation environments.

Packaging Machinery: Speed with Accuracy

In fast-moving packaging lines, actuators must be fast, consistent, and durable. Ball screw linear units are used in filling, sealing, labeling, and palletizing—ensuring each product is handled with consistent accuracy and minimal waste.

Aerospace Industry: High-Stakes Motion Control

From flight simulators to actuation systems in aircraft, the aerospace sector relies on the load-bearing strength and precise motion of ball screw linear actuators. Their reliability under extreme conditions is key to safety and performance.

Automotive Manufacturing: Powering Assembly Lines

In automotive production, these actuators are used in vehicle assembly, material handling, and quality control machines. Their efficiency and precision ensure that every component—from doors to drivetrains—is placed and tested with exacting standards.

Photovoltaic Industry: Supporting Green Energy

Ball screw linear actuators contribute to the automation of solar panel production, enabling accurate placement, bonding, and inspection of photovoltaic cells. Their role is key to driving both quality and throughput in solar tech manufacturing.

Summary: Why Ball Screw Linear Actuators Lead in Industrial Motion

Across industries, the ball screw linear actuator is synonymous with:

High-precision linear motion

Low-friction, long-lasting performance

Efficient energy use with minimal backlash

Versatility in harsh, high-speed environments

Whether it’s for semiconductor accuracy, robotic control, or industrial automation, these actuators are foundational in building the machines that build the future.

2.jpg)