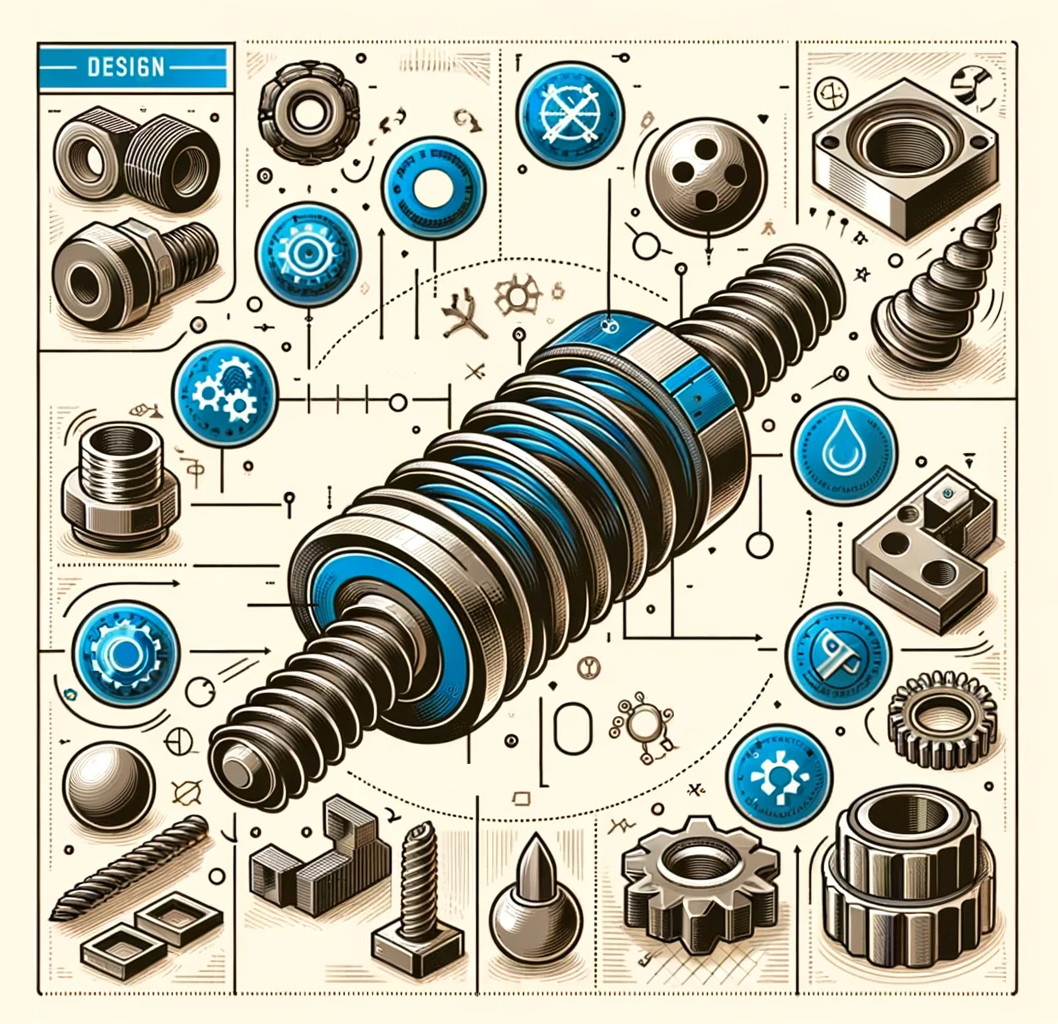

Optimizing Ball Screw Performance: Key Factors and Best Practices

Ball screws are crucial components in various applications, ranging from industrial machinery to aerospace technology. Their efficiency, precision, and longevity are affected by multiple factors, each playing a pivotal role in the overall performance of ball screw systems, including ball screw linear actuators and ball screw CNC machines.

Critical Performance Factors

Design and Material Quality

The architecture of ball screws and the caliber of materials used, particularly for the ball screw nut and bearings, are foundational to their performance. Ball screws must be designed with precision, and high-quality materials are essential for ensuring durability and reliability.

Lubrication

Optimal lubrication is vital for reducing friction and wear, especially in high-speed applications. Regular and appropriate lubrication, as discussed in the context of ball screw vs lead screw systems, plays a significant role in maintaining the health and efficiency of ball screws.

Alignment and Installation

The accuracy in the alignment and installation of ball screws and their components, including the ball screw bearing, is imperative. Correct installation ensures smooth operation and minimizes the risk of premature wear, which could otherwise necessitate ball screw repair.

Environmental and Operational Considerations

Temperature and Contamination

Ball screws operating in extreme temperatures or contaminated environments may experience degraded performance. This makes it essential to consider the environmental conditions when selecting ball screws for specific applications.

Load and Speed

The load capacity and operational speed of ball screws should be compatible with the demands of the application. Understanding the differences, such as in ball screw lead, between various types of screws, is important for optimal selection and use.

The performance of ball screws is influenced by a diverse range of factors, from their design and material quality to the environmental conditions and operational parameters they are subjected to. This highlights the importance of understanding the nuances of ball screw vs lead screw systems, and the criticality of regular maintenance, such as lubrication and alignment checks. Optimizing these factors is essential for the effective and efficient functioning of ball screw systems in various high-precision applications.