How to choose linear units?

We talk very often about linear motion system, and we, LIMON has also said that we are dedicate to it, as we all know that linear motion, also called rectilinear motion, is one-dimensional motion along a straight line, and can therefore be described mathematically using only one spatial dimension. And linear motion system is a fascinating area, it leads to an industry and linear actuators is one of the finished products from it, we’d also call it linear units. It’s an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor.

They have many kinds of uses, they mainly used in machine tools and industrial machinery, also they can be used in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

There are four basic types of linear units: mechanical/electro mechanical linear units, hydraulic linear units, pneumatic linear units and piezoelectric linear units. Here we only talk about mechanical/electro mechanical linear units.

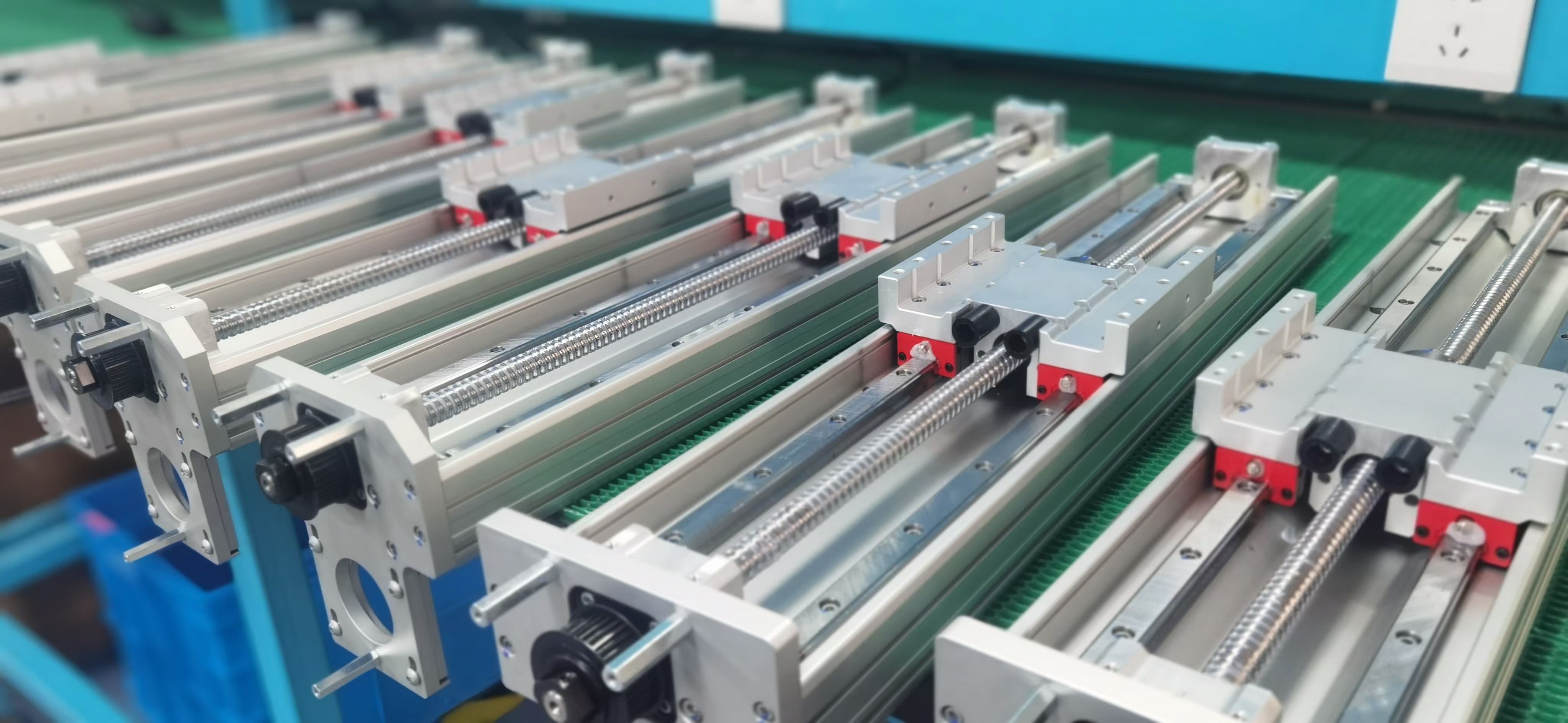

Mechanical linear units typically operate by conversion of rotary motion into linear motion. The most common mechanisms include the screw (ball screw, roller screw, or lead screw designs) and the wheel and axle (belt, chain, cable, or rack).

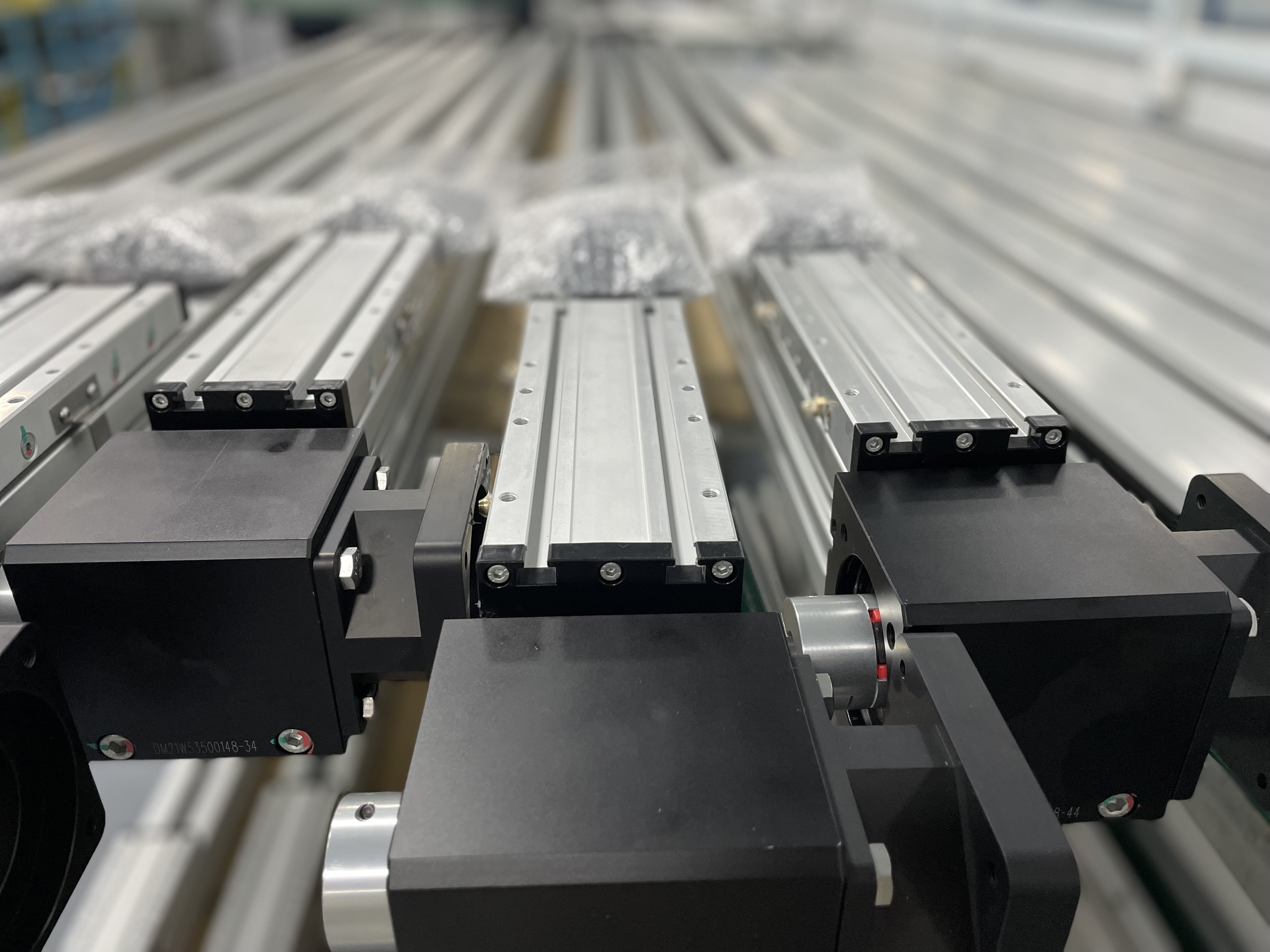

This is what we often hear from others about linear modules, linear slides, slide modules, etc. in fact, these are linear units. In the field of automation industry, they are called single axis linear motion devices. Because they can be combined into multi axis rectangular coordinate manipulators, such as cross combination, gantry type, etc., they are widely used. Now the market has higher and higher requirements for the quality of linear modules, so for our customers, how to choose linear units.

1. How to choose linear units - Accurate accuracy

It is believed that most customers in the linear units will pay attention to the accuracy. Because the biggest advantage of machinery is that the precision of machinery is much higher than that of manpower, and it will not change too much precision with the passage of time, which can reduce the consumption of manpower.

The conventional accuracy standards are divided into repeated positioning accuracy and linear positioning accuracy, and we often say that repeated positioning accuracy. This is the problem encountered in most of the selection. At present, the accuracy of the standard screw sliding table can reach ± 0.01mm, while the accuracy of the belt sliding table can reach ± 0.04mm, most industries can basically meet their daily needs.

On the contrary, in high-precision equipment and instruments such as laser detection, the accuracy requirements will be relatively high, so the grinding screw rod needs to be selected, and its accuracy can reach ± 0.04um, which is close to the accuracy of linear motor, and the cost will be much more expensive. Generally, the standard sliding table adopts cold-rolled screw rod, and the grinding screw rod will be selected only for specific different requirements, In the basic daily work, the standard can meet everyone.

2. How to choose linear units - Overall design style

For industrial production, the design of linear units pays more attention to practicability. It is best to reduce the use space, have enough bearing capacity and realize compact design.

3.How to choose linear units - Choose according to your own needs

The above three aspects are the main parameters that should be considered in the selection of linear units.

Such as operating environment, equipment load, specific stroke, driving speed, accuracy value required by equipment, brand of motor matching, with these requirements, we can basically know the general scope of type selection and how to choose linear units for yourselves.

In addition to fully considering these parameters, in order to ensure the stable performance and ultra-high quality of the equipment in use, we should make a full research on the market before purchasing and purchase the most high-quality equipment.

These are points that you need consider before you buy linear units, and if you have any questions, feel free to let us know. LIMON attaches great importance to the performance, reliability and reputation of customers. We have adhered to high standards for the accuracy and reliability of key equipment over the years, it would be our pleasure to provide service for you. Just don’t hesitate to leave us a message and get in touch with us!