Brief Introduction of our linear motion machines

Linear motion system plays a very important role in the field of automation. The linear motion machines have the advantages of simple structure, easy manufacture, reliable operation, long transmission distance and large load transmission, and can realize the law of quick return motion. If you are new to here, you will have a general cognition of linear motion machines in the linear motion system filed after reading this article.

Linear bushing-linear motion machines

This product also be called like linear bearing, linear bearing bushing, which is a linear motion system/linear motion machine, which is used for linear stroke and cylindrical shaft. Because the bearing ball contacts with the bearing jacket point, the steel ball rolls with the minimum friction resistance, so the linear bearing has small friction and is relatively stable. It does not change with the bearing speed, and can obtain a stable linear motion with high sensitivity and high precision.

Nowadays, linear bearings are more and more widely used in precision equipment or special machinery industries such as electronic equipment, food machinery, packaging machinery, medical machinery, printing machinery, textile machinery, machinery, instruments, robots, tool machinery, CNC machine tools, automobiles and digital three-dimensional coordinate measurement equipment.

- According to specification and system:

It is divided into two series, LM and LME series Its code LM series is used in Asia, Southeast Asian countries, Japan, South Korea, China and so on. Taking the metric dimension as the standard, the outer diameter tolerance of the matched linear shaft is generally H7. LME series are mostly used in Europe, the United States, Germany, Italy and other regions. The standard is British dimension, and metric dimension is also available. The outer diameter tolerance of linear shaft is generally G6. The structural characteristics of the two series are roughly the same except for different dimensions and different aperture tolerances.

- According to shape:

1: Straight cylinder type (the shape is like a cylinder, which is generally installed with snap ring, and is used in occasions with small installation size)

2: Flange type (there is a mounting flange at the end or in the middle, which can be installed with screws. The flange is generally divided into round, square and trimming types)

3: The shape of the opening type is like a straight cylinder, with axial slit on the surface. It is used for occasions requiring clearance adjustment, which is divided into two types: large opening and small opening)

Linear guideway-linear motion machines

Linear guideway, also known as guide rail, linear guide rail, slide rail, linear guide rail and linear slide rail, is used for high-precision or high-speed linear reciprocating motion. It can bear a certain torque and realize high-precision linear motion under high load.

The function of linear guide rail motion is to support and guide moving parts to make reciprocating linear motion in a given direction. Linear bearing and linear shaft are matched. Linear guide rail is mainly used in mechanical structures with high precision requirements. Rolling steel balls are used instead of intermediate media between moving elements and fixed elements of linear guide rail.

Linear guide rail is a precision part as a linear motion machine, so it is required to be quite cautious in use. Even if high-performance linear guide rail is used, if it is not used properly, it can not achieve the expected performance effect, and it is easy to damage the linear guide rail. The following precautions shall be taken when using straight guide rail:

- Prevent corrosion

When directly taking the linear guide rail by hand, fully wash the sweat from your hands and apply high-quality mineral oil before operation. Pay special attention to rust prevention in rainy season and summer.

- Keep the environment clean

Keep the linear guide rail and its surrounding environment clean. Even small dust invisible to the naked eye will increase the wear, vibration and noise of the guide rail.

- The installation shall be careful

The linear guide rail shall be used and installed carefully. It is not allowed to press strongly, directly knock the guide rail with a hammer, and transfer pressure through the rolling body.

- The installation tools shall be appropriate

Proper and accurate installation tools shall be used for the linear guide rail, special tools shall be used as far as possible, and things such as cloth and short fiber shall be avoided.

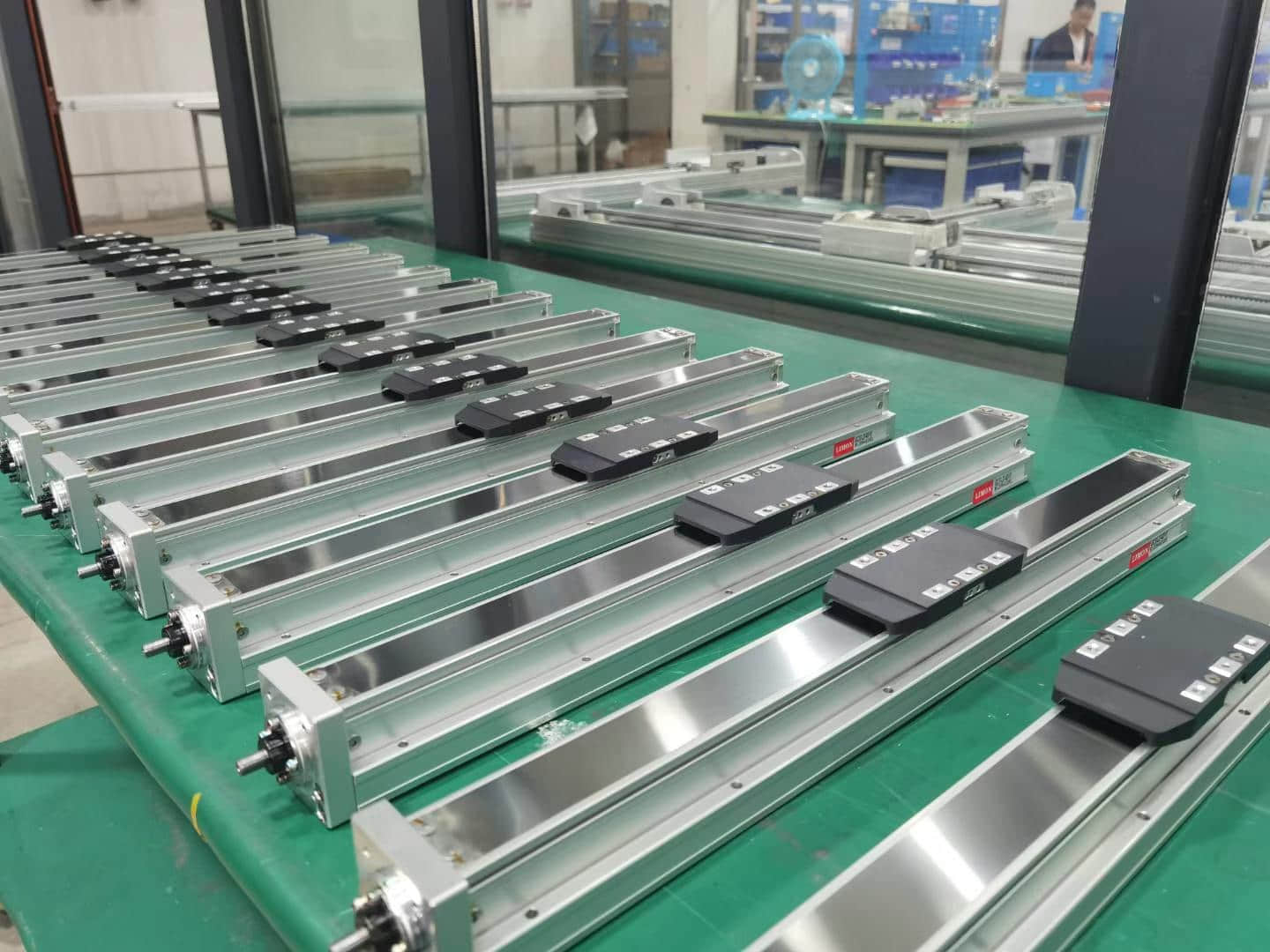

Linear actuator-linear motion machines

There are several names for linear actuator in the linear motion machines, such as linear module, rectangular coordinate robot and linear slide. It is an automatic upgrading unit following linear guide rail, linear motion module and ball screw linear transmission mechanism. The linear and curvilinear movement of load can be realized through the combination of various units, making the automation of light load more flexible and positioning more accurate.

The application scope of linear module has been expanding and running all over the world. It runs faster in our country. In recent years, the development of linear module is faster. Especially in Zhejiang, it has done a lot, and the quality is also good, which is deeply favored by equipment manufacturers.

Up to now, linear module has been widely used in a variety of equipment. China's enthusiasm for R & D and manufacturing of complete sets of equipment has reduced the indispensable contribution of engineers to the development of foreign manufacturing. At present, linear module has been widely used in measurement, laser welding, laser cutting, gluing machine, spraying machine, punching machine, dispensing machine, small CNC machine tool, engraving and milling machine, sample plotter, cutting machine, transfer machine, sorting machine, testing machine and applicable education.

At present, the widely used linear modules can be divided into three types: timing belt type, ball screw type and linear motor model.

- The timing belt type linear module

Belt driven linear units as linear motion machines is mainly composed of: belt, linear guide rail, aluminum alloy profile, coupling, motor, photoelectric switch, etc. The belt is installed on the transmission shaft on both sides of the linear module. As the power input shaft, a sliding block for adding equipment workpieces is fixed on the belt. When there is input, the slider moves by driving the belt.

- The ball screw type linear module

Ball screw driven linear units as linear motion machines is mainly composed of: ball screw, linear guide rail, aluminum alloy profile, ball screw support seat, coupling, motor, photoelectric switch, etc. The function of ball screws is to convert rotary motion into linear motion, which is the further extension and development of ball screw. The significance of this development is to change the bearing from rolling action to sliding action. Due to its small friction resistance, ball screw is widely used in various industrial equipment and precision instruments. It can realize high precision linear motion under high load.

- Linear motor module

Linear motor modules as a linear motion machine is a kind of transmission device that directly converts electric energy into linear motion mechanical energy without any intermediate conversion mechanism. The utility model has the advantages of simple structure, convenient realization of long stroke, high acceleration, fast response and high precision, and the maximum repeated positioning accuracy is ± 0.001 μ m.